Table of Contents

Benefits of Using an Automatic Dust Proof Cover Pressing Capping Machine

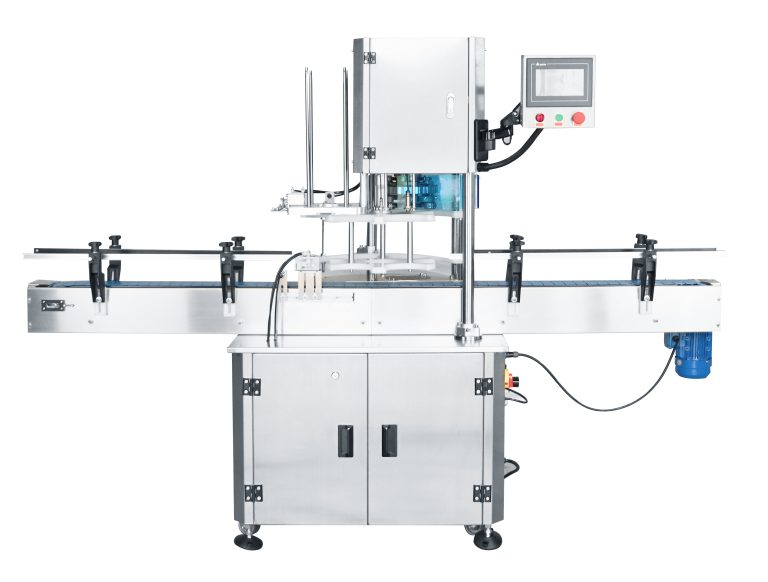

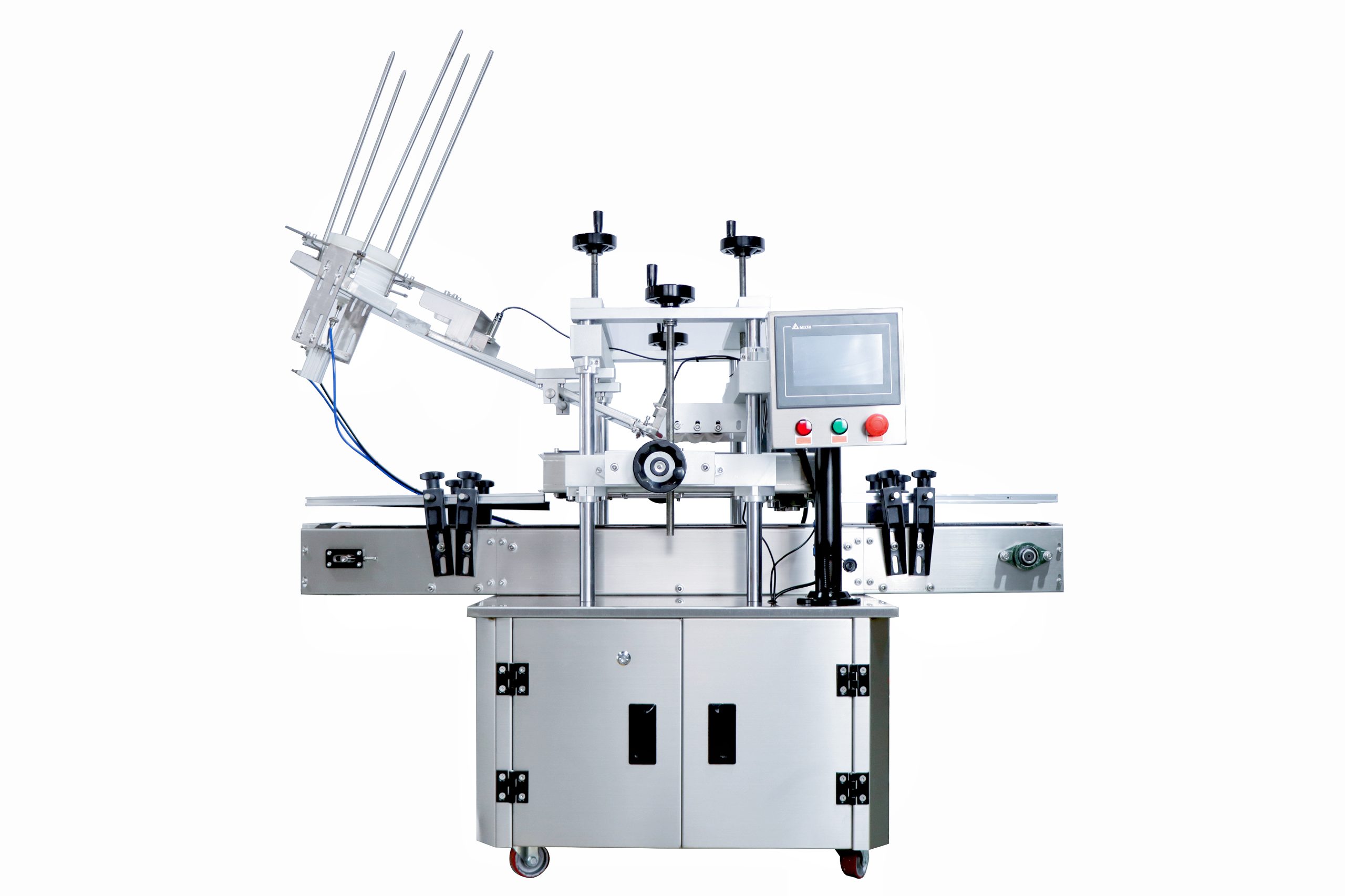

In today’s fast-paced world, efficiency and productivity are key factors in the success of any business. One way to streamline operations and increase output is by investing in automated machinery. One such machine that can greatly benefit businesses in the packaging industry is the automatic dust proof cover pressing capping machine.

This innovative piece of equipment is designed to automatically press and cap dust-proof covers onto containers, saving time and labor costs. By eliminating the need for manual labor, businesses can increase their production capacity and reduce the risk of human error. This not only improves efficiency but also ensures a consistent and high-quality end product.

One of the key benefits of using an automatic dust proof cover pressing capping machine is its speed. With the ability to cap hundreds of containers per minute, this machine can significantly increase production output. This is especially important for businesses with high-volume packaging needs, as it allows them to meet customer demands in a timely manner.

In addition to speed, the automatic dust proof cover pressing capping machine also offers precision and accuracy. The machine is programmed to apply the correct amount of pressure when pressing and capping covers onto containers, ensuring a secure seal every time. This level of consistency is crucial in maintaining product quality and preventing leaks or contamination.

Furthermore, the automatic dust proof cover pressing capping machine is versatile and can be easily adjusted to accommodate different container sizes and shapes. This flexibility allows businesses to use the machine for a variety of packaging needs, making it a cost-effective investment in the long run.

Another advantage of using this machine is its durability and reliability. Built with high-quality materials and advanced technology, the automatic dust proof cover pressing capping machine is designed to withstand the rigors of continuous use. This means businesses can rely on the machine to perform consistently day in and day out, without the need for frequent maintenance or repairs.

Moreover, the automatic dust proof cover pressing capping machine is easy to operate and requires minimal training. This makes it accessible to businesses of all sizes, regardless of their level of technical expertise. By simplifying the packaging process, businesses can focus on other aspects of their operations and improve overall efficiency.

In conclusion, the automatic dust proof cover pressing capping machine offers a wide range of benefits for businesses in the packaging industry. From increased speed and precision to versatility and reliability, this machine is a valuable asset that can help businesses streamline their operations and improve productivity. By investing in automated machinery like the automatic dust proof cover pressing capping machine, businesses can stay ahead of the competition and meet the demands of today’s fast-paced market.

How to Choose the Right Automatic Dust Proof Cover Pressing Capping Machine for Your Business

In today’s fast-paced business world, efficiency and productivity are key factors in determining the success of a company. One way to streamline operations and increase output is by investing in the right machinery and equipment. When it comes to packaging products, an automatic dust proof cover pressing capping machine can be a game-changer for businesses looking to improve their packaging process.

These machines are designed to automatically press and cap dust-proof covers onto containers, saving time and labor costs. With the ability to handle a wide range of container sizes and shapes, these machines are versatile and can be customized to meet the specific needs of different industries.

When choosing the right automatic dust proof cover pressing capping machine for your business, there are several factors to consider. First and foremost, you need to assess the volume of production and the types of containers you will be working with. This will help you determine the size and capacity of the machine that will best suit your needs.

Additionally, you should consider the speed and efficiency of the machine. Look for a machine that can handle high production volumes without compromising on quality. A machine with adjustable speed settings can help you optimize your production process and meet tight deadlines.

Another important factor to consider is the ease of operation and maintenance. Look for a machine that is user-friendly and comes with clear instructions for setup and operation. Additionally, choose a machine that is easy to clean and maintain to ensure smooth and uninterrupted operation.

When it comes to choosing a supplier for your automatic dust proof cover pressing capping machine, it is important to do your research and select a reputable and reliable company. Look for a supplier with a proven track record of delivering high-quality machinery and excellent customer service. Additionally, consider factors such as warranty, after-sales support, and spare parts availability when making your decision.

In conclusion, investing in an automatic dust proof cover pressing capping machine can greatly improve the efficiency and productivity of your packaging process. By considering factors such as production volume, speed, ease of operation, and supplier reputation, you can choose the right machine for your business and take your packaging process to the next level. With the right machine in place, you can streamline your operations, reduce labor costs, and increase output, ultimately leading to greater success and profitability for your business.