Table of Contents

Benefits of Using Aluminum Bottle Screw Capping Machines

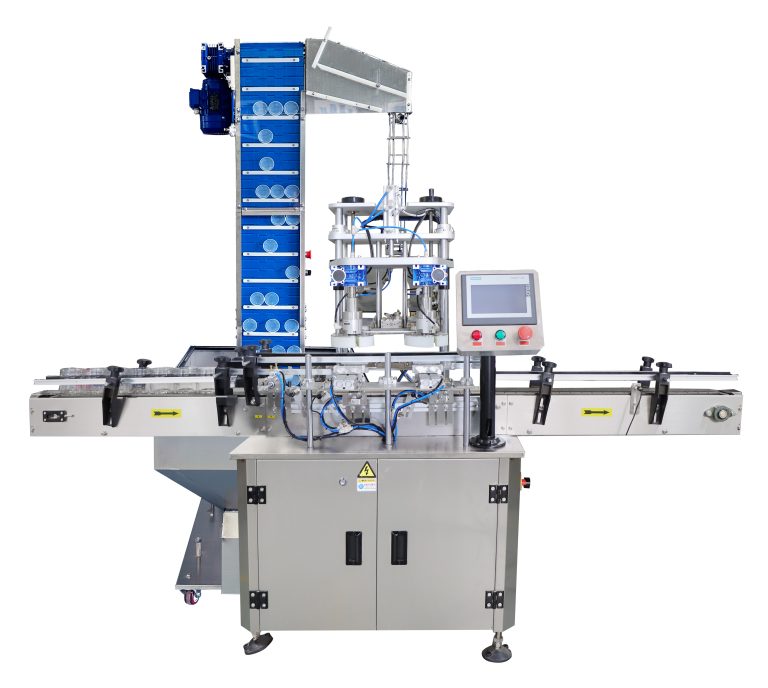

Aluminum bottle screw capping machines are essential equipment for businesses in the beverage industry. These machines are designed to efficiently seal aluminum bottles with screw caps, ensuring a secure and tamper-evident closure. There are several benefits to using aluminum bottle screw capping machines, which make them a valuable investment for companies looking to streamline their production processes and improve product quality.

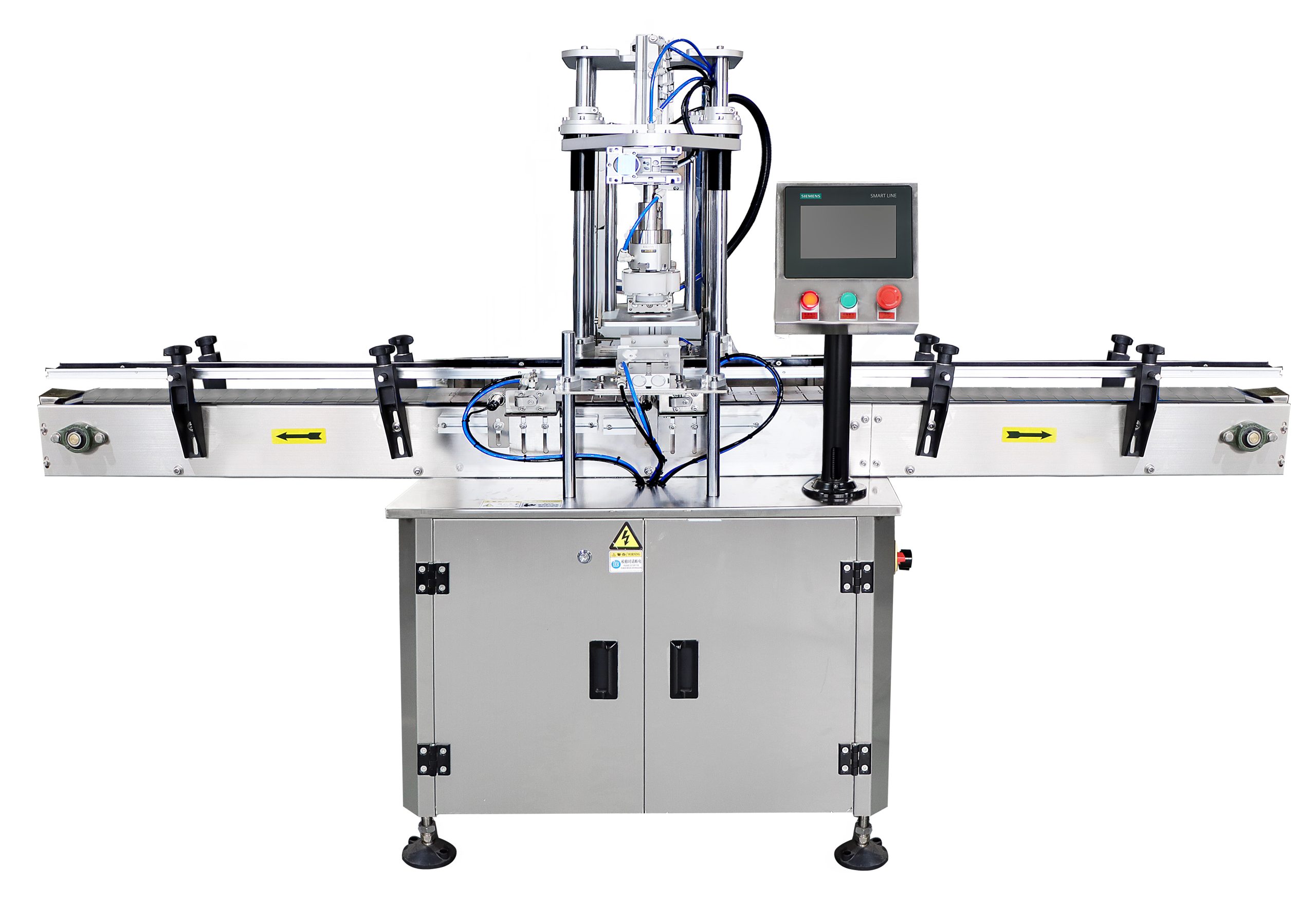

One of the key benefits of using aluminum bottle screw capping machines is their ability to provide a consistent and reliable seal on each bottle. These machines are equipped with precision capping heads that can adjust to different bottle sizes and cap types, ensuring a tight and uniform seal every time. This level of consistency is crucial for maintaining product quality and preventing leaks or contamination during storage and transportation.

In addition to ensuring a secure seal, aluminum bottle screw capping machines also help to increase production efficiency. These machines are capable of capping hundreds of bottles per minute, significantly reducing the time and labor required for manual capping. By automating the capping process, businesses can increase their output and meet customer demand more effectively.

Furthermore, aluminum bottle screw capping machines are designed to be user-friendly and easy to operate. Most machines come equipped with intuitive controls and settings that can be adjusted to suit different production requirements. This makes it easy for operators to set up the machine, monitor the capping process, and make any necessary adjustments on the fly.

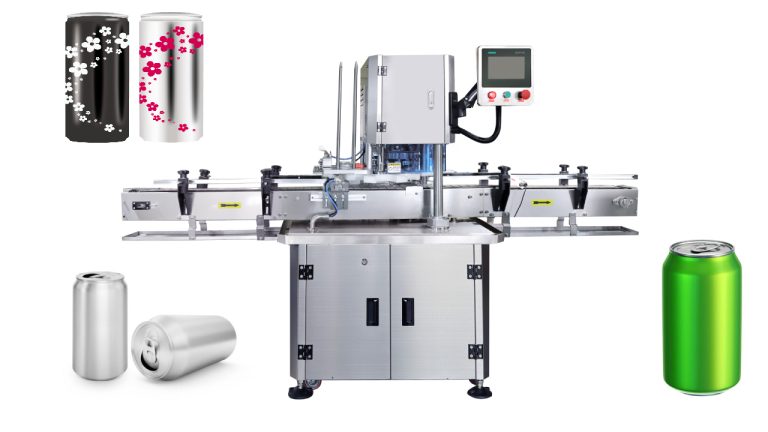

Another benefit of using aluminum bottle screw capping machines is their versatility. These machines can be used to cap a wide range of bottle sizes and shapes, making them suitable for various types of beverages, including water, soft drinks, juices, and alcoholic beverages. This flexibility allows businesses to use the same machine for different products, reducing the need for multiple capping machines and saving on costs.

Additionally, aluminum bottle screw capping machines are built to last and require minimal maintenance. These machines are constructed from high-quality materials that are resistant to corrosion and wear, ensuring long-term durability and reliability. With proper care and regular servicing, aluminum bottle screw capping machines can provide years of trouble-free operation, making them a cost-effective investment for businesses.

In conclusion, aluminum bottle screw capping machines offer numerous benefits for businesses in the beverage industry. From ensuring a secure and consistent seal to increasing production efficiency and versatility, these machines are essential for streamlining production processes and improving product quality. With their user-friendly design and long-term durability, aluminum bottle screw capping machines are a valuable asset for any company looking to enhance their capping capabilities. If you are in need of a reliable supplier for aluminum bottle screw capping machines, be sure to choose a reputable manufacturer that offers quality equipment and excellent customer support.

How to Choose the Right Aluminum Bottle Screw Capping Machine Supplier

When it comes to choosing the right aluminum bottle screw capping machine supplier, there are several factors to consider. From the quality of the machines to the level of customer service provided, finding the right supplier can make a significant impact on your business operations. In this article, we will discuss some key points to keep in mind when selecting a supplier for your aluminum bottle screw capping machines.

One of the first things to consider when choosing a supplier is the quality of the machines they offer. It is essential to ensure that the machines are durable, reliable, and capable of meeting your production needs. Look for suppliers who have a reputation for providing high-quality machines that are built to last. You may also want to consider the technology used in the machines, as newer technologies can often offer improved efficiency and performance.

In addition to the quality of the machines, it is also important to consider the level of customer service provided by the supplier. A supplier who is responsive, knowledgeable, and willing to go the extra mile to help you with any issues that may arise can make a significant difference in your overall experience. Look for suppliers who have a reputation for excellent customer service and who are willing to work closely with you to ensure that your needs are met.

Another important factor to consider when choosing a supplier is the cost of the machines. While it is essential to find a supplier who offers competitive pricing, it is also important to consider the overall value that the supplier provides. Look for suppliers who offer a good balance of quality, customer service, and affordability. It may be worth paying a little more for a supplier who offers superior machines and excellent customer service, as this can ultimately save you time and money in the long run.

When researching potential suppliers, be sure to ask for references from other customers who have purchased machines from them. This can give you valuable insight into the supplier’s reputation and the level of satisfaction that other customers have experienced. Additionally, consider visiting the supplier’s facility to see the machines in action and to get a better sense of their capabilities.

Finally, when choosing a supplier, it is important to consider their location and shipping capabilities. A supplier who is located close to your facility can often provide faster shipping times and lower shipping costs. Additionally, consider whether the supplier offers installation and training services, as this can help ensure that your machines are set up correctly and that your staff is properly trained to operate them.

In conclusion, choosing the right aluminum bottle screw capping machine supplier is a crucial decision that can have a significant impact on your business. By considering factors such as machine quality, customer service, cost, and location, you can find a supplier who meets your needs and helps you achieve your production goals. Take the time to research potential suppliers, ask for references, and visit their facilities to make an informed decision that will benefit your business in the long run.