Table of Contents

Benefits of Using Automatic Seamer Machine for Aluminum Beverage Can

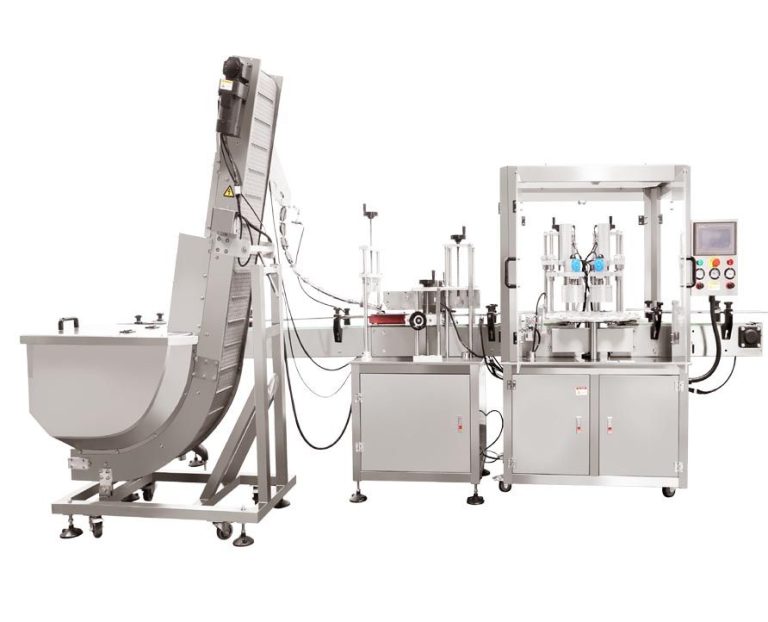

The automatic seamer machine for aluminum beverage cans is a crucial piece of equipment in the production process of canned beverages. This machine plays a vital role in ensuring that the cans are sealed properly, preventing any leaks or contamination of the contents inside. There are several benefits to using an automatic seamer machine for aluminum beverage cans, which we will explore in this article.

One of the primary benefits of using an automatic seamer machine is the efficiency it brings to the production process. These machines are designed to seal cans quickly and accurately, allowing for high-speed production without compromising on the quality of the seal. This increased efficiency can lead to cost savings for manufacturers, as it reduces the amount of time and labor required to seal each can manually.

In addition to efficiency, automatic seamer machines also offer consistency in the sealing process. These machines are programmed to seal each can in the same way, ensuring that every can is sealed to the same standard. This consistency is crucial in maintaining the quality of the product and preventing any issues with leaking or contamination. By using an automatic seamer machine, manufacturers can have peace of mind knowing that each can is sealed correctly every time.

Another benefit of using an automatic seamer machine is the reduction in waste. When cans are sealed manually, there is a higher risk of human error, which can lead to improperly sealed cans that need to be discarded. Automatic seamer machines eliminate this risk by sealing cans accurately and consistently, reducing the amount of waste generated during the production process. This not only saves money for manufacturers but also helps to reduce the environmental impact of production.

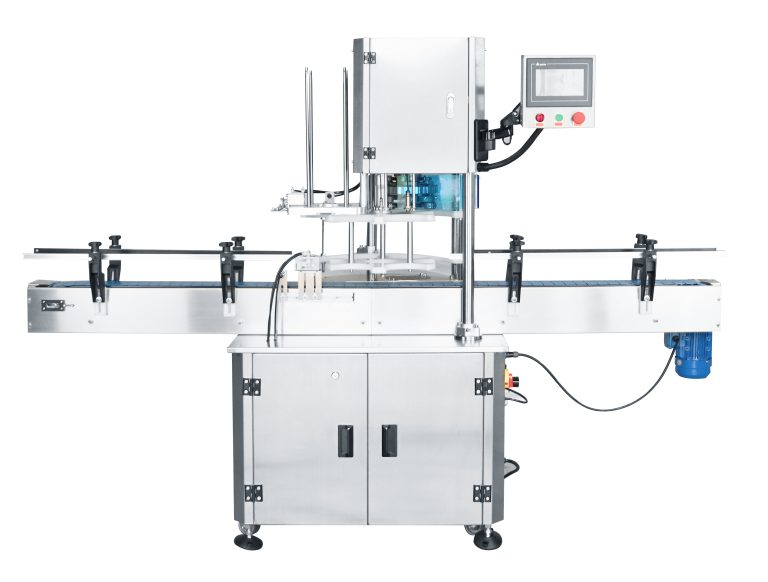

Furthermore, automatic seamer machines are designed to be user-friendly, making them easy to operate and maintain. These machines are equipped with intuitive controls and features that make it simple for operators to set up and run the machine. Additionally, automatic seamer machines are built to be durable and reliable, requiring minimal maintenance to keep them running smoothly. This ease of use and low maintenance requirements make automatic seamer machines a practical choice for manufacturers looking to streamline their production process.

In conclusion, the automatic seamer machine for aluminum beverage cans offers a range of benefits for manufacturers looking to improve their production process. From increased efficiency and consistency to reduced waste and ease of use, these machines are a valuable investment for any beverage canning operation. By utilizing an automatic seamer machine, manufacturers can ensure that their cans are sealed properly every time, leading to a high-quality product that meets consumer expectations.

How to Choose the Right Automatic Seamer Machine for Aluminum Beverage Can

Automatic seamers are essential machines in the beverage industry for sealing aluminum cans. These machines ensure that the cans are properly sealed to maintain the freshness and quality of the beverages inside. Choosing the right automatic seamer machine for aluminum beverage cans is crucial to ensure efficient production and high-quality sealing. There are several factors to consider when selecting an automatic seamer machine, including speed, can size compatibility, seam quality, and ease of maintenance.

One of the most important factors to consider when choosing an automatic seamer machine is the speed at which it can seal cans. The speed of the machine will directly impact the production output of your facility. It is essential to select a machine that can keep up with the demand of your production line to avoid bottlenecks and delays. Additionally, a faster machine can help increase efficiency and reduce labor costs.

Another critical factor to consider is the compatibility of the automatic seamer machine with the size of aluminum cans used in your production line. Different machines are designed to handle specific can sizes, so it is essential to choose a machine that can accommodate the cans you use. Using a machine that is not compatible with your can sizes can result in improper sealing and wasted materials.

Seam quality is another crucial consideration when selecting an automatic seamer machine. The quality of the seam will directly impact the shelf life and freshness of the beverages inside the cans. It is essential to choose a machine that can consistently produce high-quality seams to ensure the integrity of the cans. Poor seam quality can lead to leaks, contamination, and spoilage of the beverages, resulting in financial losses and damage to your brand reputation.

Ease of maintenance is also an important factor to consider when choosing an automatic seamer machine. Regular maintenance is essential to keep the machine running smoothly and prevent breakdowns. Selecting a machine that is easy to maintain can help reduce downtime and ensure continuous production. Look for machines that are designed for easy access to components for cleaning and maintenance.

When choosing an automatic seamer machine for aluminum beverage cans, it is essential to consider all these factors to ensure efficient production and high-quality sealing. Evaluate your production needs, can sizes, seam quality requirements, and maintenance preferences to select the right machine for your facility. Investing in a high-quality automatic seamer machine will help improve production efficiency, reduce costs, and ensure the quality of your canned beverages.

In conclusion, selecting the right automatic seamer machine for aluminum beverage cans is crucial for the success of your production line. Consider factors such as speed, can size compatibility, seam quality, and ease of maintenance when choosing a machine. Investing in a high-quality automatic seamer machine will help improve efficiency, reduce costs, and ensure the freshness and quality of your canned beverages. Choose wisely to ensure the success of your beverage production.

Maintenance Tips for Automatic Seamer Machine for Aluminum Beverage Can

Automatic seamers are essential machines in the beverage industry for sealing aluminum cans. These machines ensure that the cans are properly sealed to maintain the freshness and quality of the beverages inside. To ensure the seamless operation of an automatic seamer machine for aluminum beverage cans, regular maintenance is crucial. In this article, we will discuss some maintenance tips to keep your automatic seamer machine in top condition.

One of the most important maintenance tasks for an automatic seamer machine is regular cleaning. Over time, dust, debris, and residue from the cans can build up on the machine, affecting its performance. It is recommended to clean the machine after each production run to prevent any buildup. Use a soft cloth and a mild detergent to clean the exterior of the machine, and use compressed air to remove any debris from the interior components.

In addition to cleaning, it is important to regularly inspect the machine for any signs of wear and tear. Check the seams of the cans produced by the machine to ensure they are properly sealed. Inspect the rollers, chucks, and other components for any signs of damage or wear. Replace any worn or damaged parts immediately to prevent any issues during production.

Another important maintenance task for an automatic seamer machine is lubrication. Proper lubrication of the moving parts of the machine is essential to ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer to lubricate the rollers, chucks, and other moving parts of the machine. Be sure to follow the manufacturer’s guidelines for the frequency of lubrication to prevent any issues.

Regular calibration of the machine is also important to ensure accurate sealing of the cans. Over time, the settings of the machine may drift, affecting the quality of the seals. It is recommended to calibrate the machine regularly to ensure consistent and reliable performance. Follow the manufacturer’s guidelines for calibration to ensure accurate results.

In addition to regular maintenance tasks, it is important to train your operators on the proper use and maintenance of the automatic seamer machine. Proper training can help prevent any issues that may arise due to operator error. Ensure that your operators are familiar with the machine’s operation, maintenance tasks, and safety procedures to prevent any accidents or damage to the machine.

By following these maintenance tips, you can ensure that your automatic seamer machine for aluminum beverage cans remains in top condition and continues to produce high-quality sealed cans. Regular cleaning, inspection, lubrication, calibration, and operator training are essential to keep the machine running smoothly and efficiently. With proper maintenance, you can extend the life of your automatic seamer machine and ensure the quality of your canned beverages.