Advantages of High Speed Automatic Can Closer Equipment

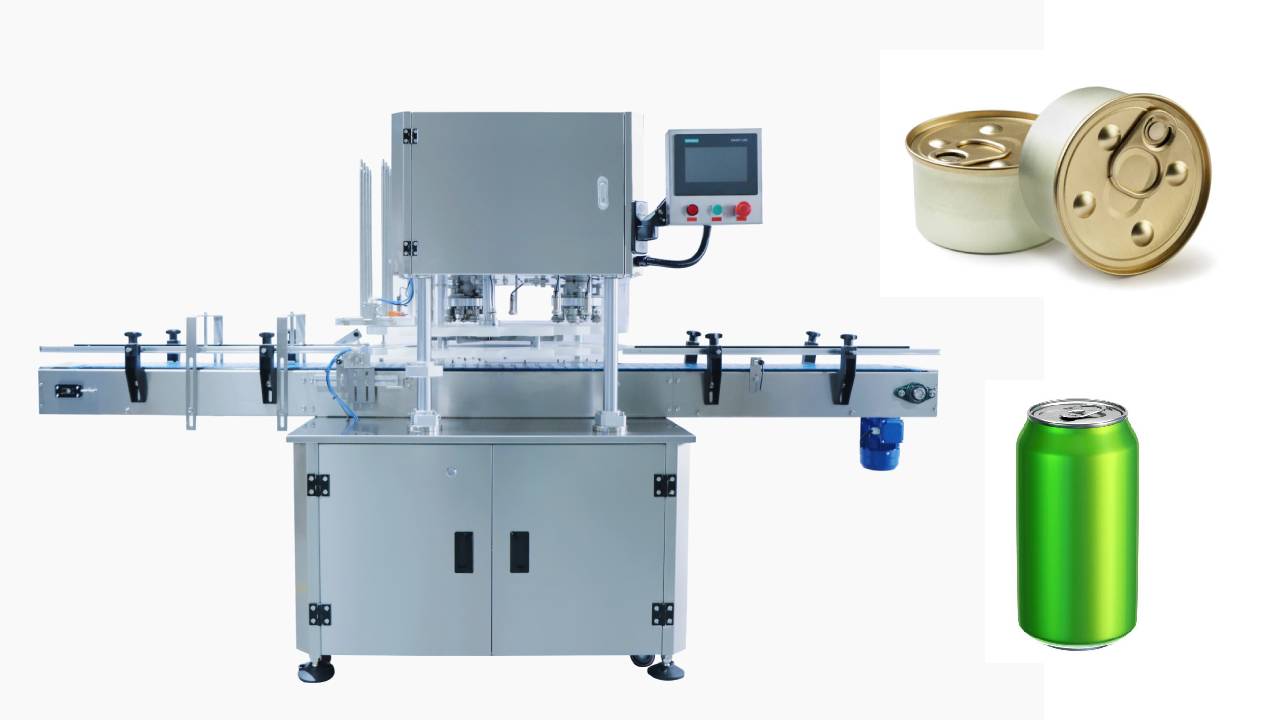

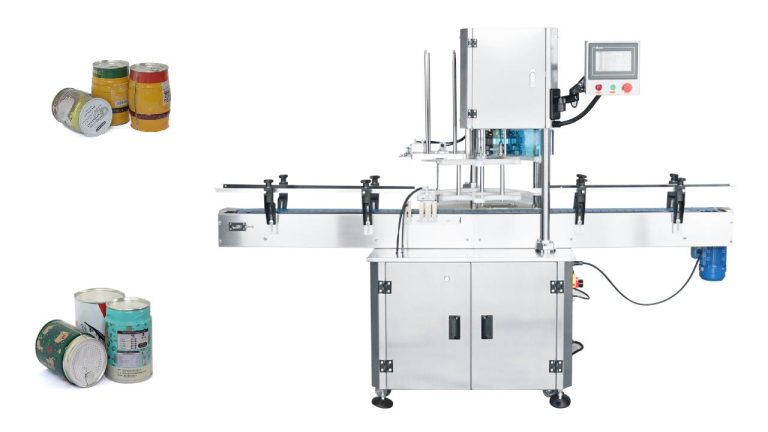

High speed automatic can closer equipment offers a range of advantages for businesses looking to streamline their packaging processes. These machines are designed to quickly and efficiently seal cans, reducing the need for manual labor and increasing overall productivity. In this article, we will explore some of the key benefits of using high speed automatic can closer equipment in a manufacturing setting.

One of the primary advantages of high speed automatic can closer equipment is its ability to significantly increase production output. These machines are capable of sealing cans at a much faster rate than manual methods, allowing businesses to package more products in less time. This can help to meet tight production deadlines and keep up with high demand, ultimately leading to increased profitability for the business.

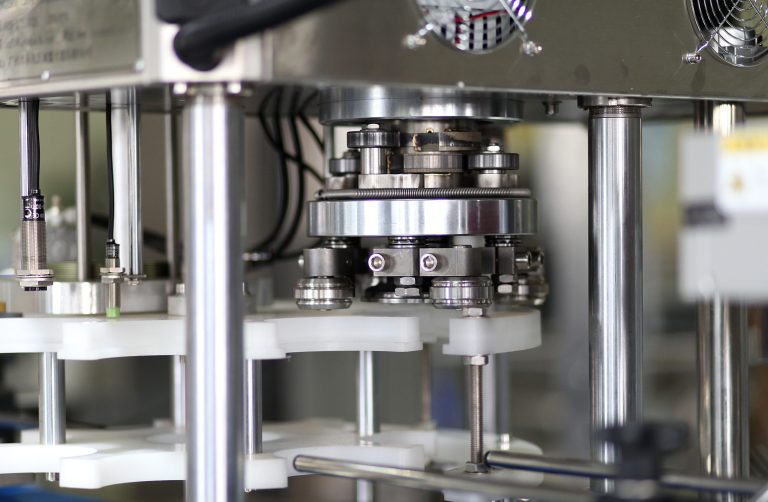

In addition to improving production efficiency, high speed automatic can closer equipment also helps to ensure consistency in the sealing process. Manual sealing methods can be prone to human error, resulting in inconsistencies in the quality of the seals. By using automated equipment, businesses can achieve a higher level of precision and accuracy in their packaging, leading to a more professional and reliable end product.

Another key advantage of high speed automatic can closer equipment is its ability to reduce labor costs. Manual sealing processes require a significant amount of manpower, which can be costly for businesses in terms of wages and benefits. By investing in automated equipment, businesses can reduce their reliance on manual labor and reallocate resources to other areas of the operation. This can help to improve overall efficiency and profitability for the business.

Furthermore, high speed automatic can closer equipment is designed to be user-friendly and easy to operate. Many machines come equipped with intuitive controls and settings that can be easily adjusted to meet the specific needs of the business. This makes it simple for operators to set up and run the equipment, reducing the need for extensive training and minimizing the risk of errors during operation.

In addition to these practical benefits, high speed automatic can closer equipment also offers a range of safety advantages for businesses. Manual sealing processes can be physically demanding and potentially hazardous for workers, leading to an increased risk of injuries on the job. By using automated equipment, businesses can create a safer working environment for their employees and reduce the likelihood of workplace accidents.

Overall, high speed automatic can closer equipment offers a range of advantages for businesses looking to improve their packaging processes. From increased production output and consistency to reduced labor costs and improved safety, these machines can help businesses to streamline their operations and achieve greater efficiency and profitability. By investing in automated equipment, businesses can stay ahead of the competition and meet the demands of a fast-paced manufacturing environment.