Table of Contents

Benefits of Using Tamarind Paste Piston Filling Machine in Food Production

Tamarind paste is a popular ingredient in many cuisines around the world, known for its tangy and sweet flavor. It is commonly used in dishes such as curries, chutneys, and sauces. In food production, tamarind paste is often used as a filling in various products such as candies, pastries, and snacks. To streamline the production process and ensure consistent quality, many food manufacturers use tamarind paste piston filling machines.

One of the key benefits of using a tamarind paste piston filling machine is efficiency. These machines are designed to fill containers with tamarind paste quickly and accurately, reducing the need for manual labor and increasing production output. With a piston filling machine, food manufacturers can fill a large number of containers in a short amount of time, helping to meet the demands of a fast-paced production environment.

In addition to efficiency, tamarind paste piston filling machines also offer precision. These machines are equipped with pistons that can accurately measure and dispense the desired amount of tamarind paste into each container. This ensures that each product is filled with the correct amount of tamarind paste, helping to maintain consistency in taste and quality. By using a piston filling machine, food manufacturers can avoid overfilling or underfilling containers, reducing waste and ensuring customer satisfaction.

Another benefit of using a tamarind paste piston filling machine is versatility. These machines can be easily adjusted to accommodate different container sizes and shapes, making them suitable for a wide range of products. Whether filling jars, bottles, or pouches, a piston filling machine can handle various types of containers with ease. This flexibility allows food manufacturers to produce a diverse range of tamarind paste products without the need for multiple filling machines.

Furthermore, tamarind paste piston filling machines are easy to clean and maintain. These machines are designed with hygiene in mind, with smooth surfaces and removable parts that can be easily cleaned and sanitized. Regular maintenance of a piston filling machine can help prolong its lifespan and ensure optimal performance. By keeping the machine clean and well-maintained, food manufacturers can prevent contamination and uphold food safety standards.

In conclusion, the use of a tamarind paste piston filling machine offers numerous benefits for food manufacturers. From increased efficiency and precision to versatility and ease of maintenance, these machines can help streamline the production process and improve product quality. By investing in a tamarind paste piston filling machine, food manufacturers can enhance their operations and meet the demands of a competitive market.

How to Choose the Right Tamarind Paste Piston Filling Machine for Your Business

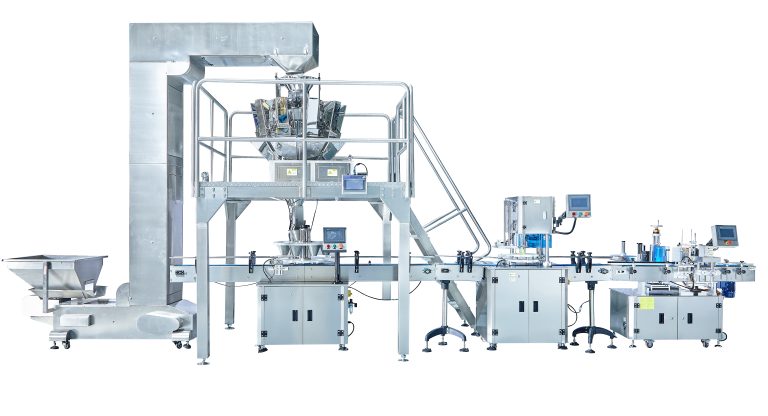

Tamarind paste is a popular ingredient in many cuisines around the world, known for its tangy and sweet flavor. If you are in the food industry and looking to streamline your production process, investing in a tamarind paste piston filling machine can be a game-changer for your business. These machines are designed to accurately fill containers with tamarind paste, saving you time and labor costs. However, with so many options available on the market, it can be overwhelming to choose the right one for your specific needs.

When selecting a tamarind paste piston filling machine, there are several factors to consider. First and foremost, you need to determine the volume of tamarind paste you will be filling on a daily basis. This will help you determine the capacity of the machine you need. If you have a high production volume, you will need a machine with a larger piston size and faster filling speed. On the other hand, if you have a smaller operation, a smaller machine may be more suitable.

Another important factor to consider is the type of containers you will be filling with tamarind paste. Different machines are designed to fill different types of containers, such as jars, bottles, or pouches. Make sure to choose a machine that is compatible with the containers you will be using to avoid any compatibility issues.

In addition to capacity and container type, you should also consider the level of automation you need in a tamarind paste piston filling machine. Some machines are fully automated, with features such as automatic filling, capping, and labeling. These machines are ideal for high-volume production facilities that require maximum efficiency. However, if you have a smaller operation or prefer more control over the filling process, a semi-automatic machine may be more suitable.

Furthermore, it is essential to consider the quality and reliability of the machine you are investing in. Look for a reputable manufacturer with a track record of producing high-quality filling machines. Read reviews and testimonials from other customers to ensure that the machine you choose is durable and built to last.

Cost is also a significant factor to consider when choosing a tamarind paste piston filling machine. While it may be tempting to opt for the cheapest option available, it is essential to consider the long-term costs associated with maintenance and repairs. Investing in a higher-quality machine may cost more upfront but can save you money in the long run by reducing downtime and maintenance costs.

In conclusion, choosing the right tamarind paste piston filling machine for your business is a crucial decision that can impact your production efficiency and overall success. Consider factors such as production volume, container type, level of automation, quality, and cost when making your decision. By taking the time to research and evaluate your options, you can find a machine that meets your specific needs and helps you streamline your tamarind paste filling process.