Table of Contents

Benefits of Investing in an Automatic Weighing Filling Seaming Machine Line for Granule, Beans, Nuts, Candy, Gummy, Can, Bottle, and Jar Packaging

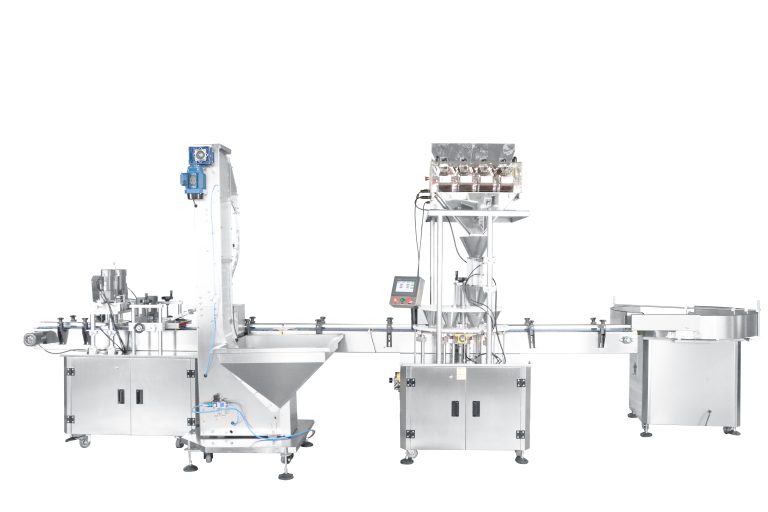

In today’s fast-paced world, efficiency and accuracy are key factors in the success of any business. When it comes to packaging granule, beans, nuts, candy, gummy, can, bottle, and jar products, investing in an automatic weighing filling seaming machine line can provide numerous benefits. These machines are designed to streamline the packaging process, ensuring that products are filled and sealed quickly and accurately.

One of the main benefits of investing in an automatic weighing filling seaming machine line is the increase in productivity. These machines are capable of filling and sealing a large number of products in a short amount of time, allowing businesses to meet high demand without sacrificing quality. This can help businesses save time and money, as manual packaging processes can be time-consuming and prone to errors.

Another benefit of automatic weighing filling seaming machine lines is the level of accuracy they provide. These machines are equipped with advanced technology that ensures products are filled to the exact weight specifications, reducing waste and ensuring consistency in product quality. This level of accuracy can help businesses maintain customer satisfaction and build a strong reputation for their products.

In addition to increased productivity and accuracy, automatic weighing filling seaming machine lines also offer versatility. These machines can be customized to accommodate a wide range of product sizes and types, making them suitable for businesses that package a variety of products. This versatility can help businesses adapt to changing market demands and expand their product offerings without the need for additional equipment.

Furthermore, investing in an automatic weighing filling seaming machine line can also improve safety in the workplace. These machines are designed with safety features that protect operators from potential hazards, reducing the risk of accidents and injuries. This can help businesses create a safer work environment and comply with industry regulations.

Overall, investing in an automatic weighing filling seaming machine line can provide businesses with a competitive edge in the market. These machines offer numerous benefits, including increased productivity, accuracy, versatility, and safety. By streamlining the packaging process and ensuring product quality, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

In conclusion, automatic weighing filling seaming machine lines are a valuable investment for businesses that package granule, beans, nuts, candy, gummy, can, bottle, and jar products. These machines offer a wide range of benefits that can help businesses improve productivity, accuracy, versatility, and safety. By investing in this advanced technology, businesses can stay ahead of the competition and achieve success in today’s competitive market.

How to Choose the Right Automatic Granule Beans Nuts Candy Gummy Can Bottle Jar Weighing Filling Seaming Machine Line for Your Production Needs

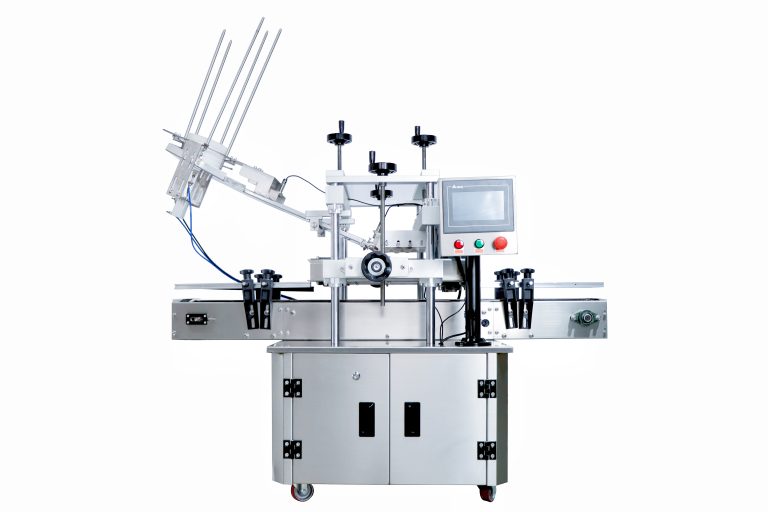

When it comes to choosing the right automatic granule beans nuts candy gummy can bottle jar weighing filling seaming machine line for your production needs, there are several factors to consider. These machines are essential for efficiently packaging products in a variety of industries, including food, pharmaceuticals, and cosmetics. By selecting the right machine line, you can increase productivity, reduce waste, and ensure the quality of your products.

One of the first things to consider when choosing an automatic weighing filling seaming machine line is the type of products you will be packaging. Different machines are designed to handle specific types of products, such as granules, beans, nuts, candy, or gummy candies. It is important to choose a machine line that is specifically designed to handle the type of products you will be packaging to ensure optimal performance and efficiency.

Another important factor to consider is the production capacity of the machine line. You will need to determine how many products you need to package per hour or per day to meet your production goals. It is essential to choose a machine line that can handle the volume of products you need to package without causing bottlenecks or delays in your production process.

In addition to production capacity, you should also consider the accuracy of the weighing and filling mechanisms in the machine line. Accurate weighing and filling are essential for ensuring that each product is packaged correctly and consistently. Look for a machine line that offers precise weighing and filling capabilities to minimize waste and ensure the quality of your products.

The speed of the machine line is another important consideration. A faster machine line can help you increase productivity and meet tight production deadlines. However, it is essential to balance speed with accuracy to ensure that each product is packaged correctly. Look for a machine line that offers a good balance of speed and accuracy to meet your production needs.

When choosing an automatic weighing filling seaming machine line, it is also important to consider the space available in your production facility. Some machine lines are larger and require more space to operate, while others are more compact and can fit into smaller spaces. Consider the layout of your production facility and choose a machine line that will fit comfortably within your space constraints.

Finally, consider the reputation of the manufacturer when choosing an automatic weighing filling seaming machine line. Look for a manufacturer with a proven track record of producing high-quality, reliable machines. Read reviews and testimonials from other customers to ensure that you are choosing a machine line from a reputable manufacturer.

In conclusion, choosing the right automatic granule beans nuts candy gummy can bottle jar weighing filling seaming machine line for your production needs is essential for ensuring the efficiency and quality of your packaging process. Consider factors such as the type of products you will be packaging, production capacity, accuracy, speed, space requirements, and the reputation of the manufacturer when making your decision. By carefully evaluating these factors, you can select a machine line that meets your production needs and helps you achieve your business goals.