Table of Contents

Benefits of Using Automatic Nail Free Glue Paper Can Flanging Seaming Machine

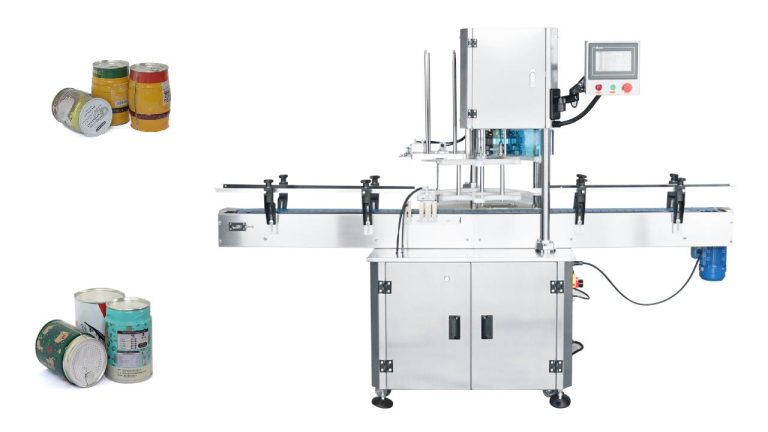

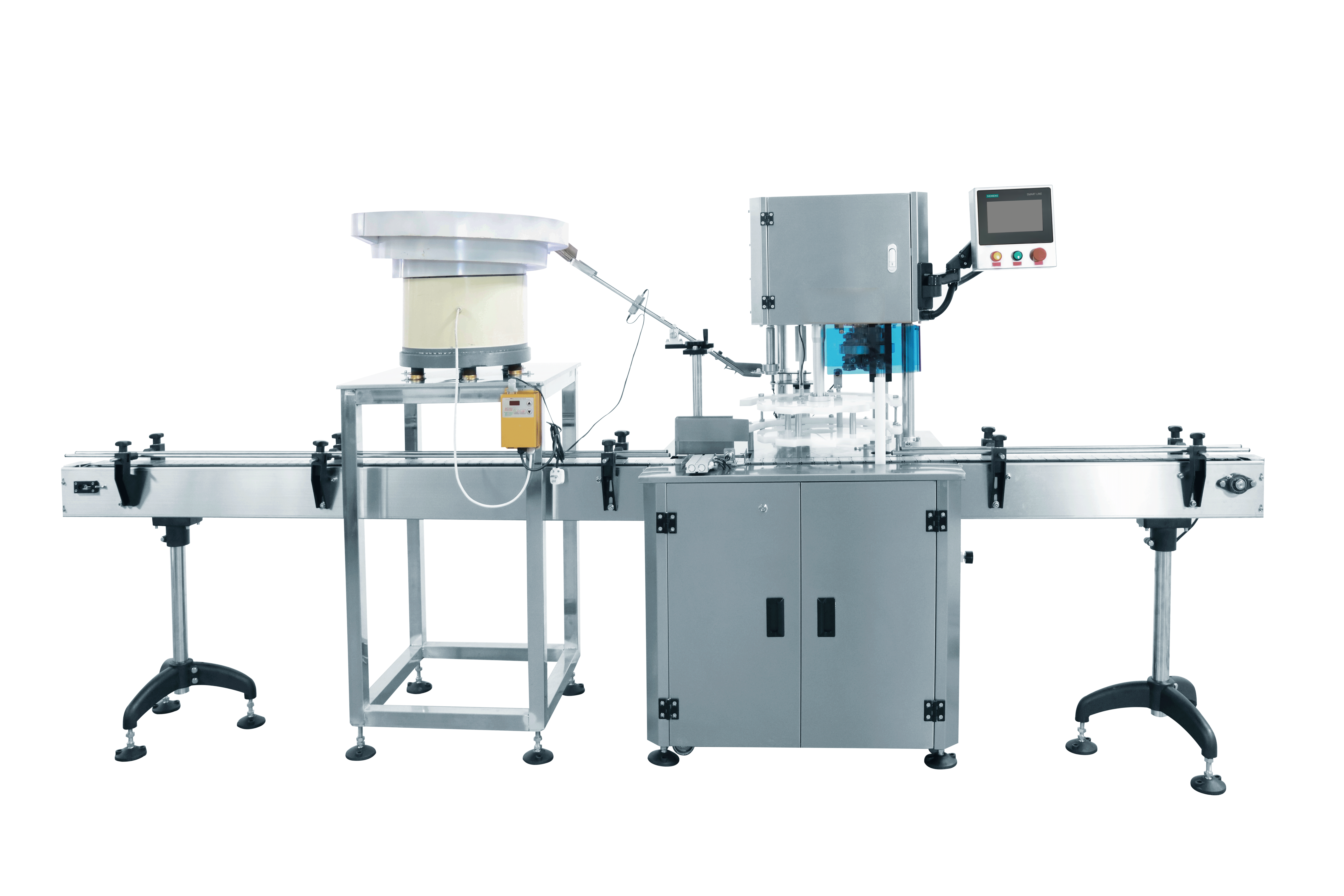

Automatic Nail Free Glue Paper Can Flanging Seaming Machine is a revolutionary piece of equipment that has transformed the way paper cans are manufactured. This machine offers a wide range of benefits that make it a valuable investment for businesses in the packaging industry.

One of the key benefits of using the Automatic Nail Free Glue Paper Can Flanging Seaming Machine is its efficiency. This machine is capable of producing a large number of paper cans in a short amount of time, significantly increasing production output. This can help businesses meet tight deadlines and fulfill large orders with ease.

In addition to its efficiency, the Automatic Nail Free Glue Paper Can Flanging Seaming Machine also offers a high level of precision. The machine is designed to accurately flange and seam paper cans, ensuring that each can is perfectly sealed and ready for use. This level of precision can help businesses maintain a high level of quality control and produce consistent, reliable products.

Another benefit of using the Automatic Nail Free Glue Paper Can Flanging Seaming Machine is its versatility. This machine is capable of working with a wide range of paper can sizes and shapes, making it suitable for a variety of packaging needs. Whether businesses are producing small, medium, or large paper cans, this machine can handle the job with ease.

Furthermore, the Automatic Nail Free Glue Paper Can Flanging Seaming Machine is easy to operate and maintain. The machine is designed with user-friendly controls and features that make it simple to set up and run. Additionally, the machine is built with durable materials that require minimal maintenance, reducing downtime and ensuring consistent performance.

One of the most significant benefits of using the Automatic Nail Free Glue Paper Can Flanging Seaming Machine is its cost-effectiveness. This machine can help businesses save money on labor costs by automating the flanging and seaming process. Additionally, the machine’s efficiency and precision can help businesses reduce waste and improve overall production efficiency, leading to long-term cost savings.

Overall, the Automatic Nail Free Glue Paper Can Flanging Seaming Machine offers a wide range of benefits that make it a valuable investment for businesses in the packaging industry. From its efficiency and precision to its versatility and cost-effectiveness, this machine can help businesses improve their production processes and deliver high-quality paper cans to their customers.

In conclusion, the Automatic Nail Free Glue Paper Can Flanging Seaming Machine is a game-changer for businesses looking to streamline their paper can manufacturing process. With its efficiency, precision, versatility, and cost-effectiveness, this machine offers a wide range of benefits that can help businesses improve their production output and deliver consistent, reliable products to their customers.

How to Choose the Right Automatic Nail Free Glue Paper Can Flanging Seaming Machine for Your Business

When it comes to choosing the right automatic nail free glue paper can flanging seaming machine for your business, there are several factors to consider. These machines are essential for efficiently sealing paper cans in various industries such as food, cosmetics, and pharmaceuticals. With the advancement of technology, there are now several options available in the market, each with its own set of features and capabilities. In this article, we will discuss some key considerations to keep in mind when selecting the right machine for your business.

First and foremost, it is important to consider the size and capacity of the machine. Depending on the volume of production in your business, you will need to choose a machine that can handle the workload efficiently. Look for machines that offer a high production capacity and can handle a wide range of can sizes. This will ensure that your production process runs smoothly without any bottlenecks.

Another important factor to consider is the speed and efficiency of the machine. Look for machines that offer fast and accurate flanging and seaming capabilities. This will help you increase productivity and meet tight deadlines. Additionally, consider machines that offer automatic nail free glue application, as this will further streamline the production process and reduce the risk of errors.

In addition to speed and capacity, it is also important to consider the quality of the finished product. Look for machines that offer precise and consistent flanging and seaming results. This will ensure that your paper cans are properly sealed and protected, maintaining the integrity of your products. Consider machines that offer adjustable settings for different can sizes and materials, as this will allow you to customize the machine to meet your specific production needs.

When choosing an automatic nail free glue paper can flanging seaming machine, it is also important to consider the overall durability and reliability of the machine. Look for machines that are made from high-quality materials and are built to last. Consider machines that offer easy maintenance and servicing options, as this will help prolong the lifespan of the machine and reduce downtime.

Furthermore, consider the level of automation and control offered by the machine. Look for machines that offer user-friendly interfaces and intuitive controls. This will make it easier for your operators to set up and operate the machine, reducing the risk of errors and increasing efficiency. Consider machines that offer advanced features such as remote monitoring and diagnostics, as this will help you track performance and troubleshoot any issues quickly.

In conclusion, choosing the right automatic nail free glue paper can flanging seaming machine for your business is a crucial decision that can impact the efficiency and productivity of your production process. Consider factors such as size, capacity, speed, quality, durability, automation, and control when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure that your business runs smoothly and efficiently.

Maintenance Tips for Automatic Nail Free Glue Paper Can Flanging Seaming Machine

Automatic nail-free glue paper can flanging seaming machines are essential tools in the packaging industry. These machines are designed to efficiently seal paper cans without the need for nails or other fasteners. However, like any piece of equipment, regular maintenance is crucial to ensure optimal performance and longevity.

One of the most important maintenance tips for automatic nail-free glue paper can flanging seaming machines is to keep them clean. Dust, debris, and adhesive residue can build up over time and affect the machine’s performance. Regularly cleaning the machine with a soft cloth and mild detergent can help prevent these issues.

In addition to keeping the machine clean, it is also important to regularly inspect and replace any worn or damaged parts. This includes checking the sealing rollers, glue applicators, and other components for signs of wear. Replacing these parts as needed can help prevent breakdowns and ensure smooth operation.

Another important maintenance tip is to regularly lubricate the moving parts of the machine. This helps reduce friction and wear, prolonging the life of the machine. Be sure to use the appropriate lubricant for each part, as using the wrong type of lubricant can cause damage.

It is also important to regularly calibrate the machine to ensure accurate sealing and flanging. This involves adjusting the settings and parameters of the machine to meet the specific requirements of the paper cans being sealed. Regular calibration can help prevent issues such as leaks or improper sealing.

Regularly inspecting the electrical components of the machine is also important. Check for loose connections, frayed wires, or other signs of damage. If any issues are found, they should be addressed promptly to prevent electrical malfunctions.

In addition to these maintenance tips, it is also important to follow the manufacturer’s guidelines for care and maintenance. This includes scheduling regular maintenance checks with a qualified technician and following any recommended maintenance procedures.

By following these maintenance tips, you can help ensure that your automatic nail-free glue paper can flanging seaming machine operates efficiently and reliably. Regular maintenance can help prevent breakdowns, extend the life of the machine, and ensure consistent sealing and flanging performance.

In conclusion, automatic nail-free glue paper can flanging seaming machines are valuable tools in the packaging industry. By following these maintenance tips, you can help ensure that your machine operates at its best and continues to meet your production needs. Regular cleaning, inspection, lubrication, calibration, and adherence to manufacturer guidelines are key to keeping your machine in top condition. Remember, a well-maintained machine is a reliable machine.