Table of Contents

Benefits of Using Automatic Nitrogen Gas Flushing Can Seamer Machine for Coffee Bean Packaging

Coffee beans are a popular commodity that is enjoyed by millions of people around the world. Whether it’s a morning pick-me-up or a mid-afternoon treat, coffee beans are a staple in many households. When it comes to packaging coffee beans, it is important to ensure that the beans stay fresh and flavorful for as long as possible. One way to achieve this is by using an automatic nitrogen gas flushing can seamer machine.

Nitrogen gas flushing can seamer machines are designed to remove oxygen from the packaging container and replace it with nitrogen gas. This process helps to create a protective barrier around the coffee beans, preventing them from coming into contact with oxygen, which can lead to oxidation and spoilage. By using nitrogen gas flushing, coffee beans can maintain their freshness and flavor for a longer period of time.

One of the key benefits of using an automatic nitrogen gas flushing can seamer machine for coffee bean packaging is the extended shelf life of the product. By removing oxygen from the packaging container, the coffee beans are less likely to spoil or go stale. This means that consumers can enjoy fresh and flavorful coffee beans for a longer period of time, without worrying about them losing their taste or aroma.

In addition to extending the shelf life of the product, nitrogen gas flushing can seamer machines also help to preserve the quality of the coffee beans. Oxygen is known to be a major contributor to the degradation of food products, causing them to lose their nutritional value and flavor. By replacing oxygen with nitrogen gas, coffee beans are protected from the harmful effects of oxidation, ensuring that they retain their quality and taste.

Another benefit of using an automatic nitrogen gas flushing can seamer machine for coffee bean packaging is the improved appearance of the product. Oxygen can cause coffee beans to lose their color and vibrancy over time, making them appear dull and unappealing. By using nitrogen gas flushing, coffee beans can maintain their rich color and visual appeal, making them more attractive to consumers.

Furthermore, nitrogen gas flushing can seamer machines are easy to use and require minimal maintenance. Once the machine is set up and calibrated, it can operate efficiently and effectively, ensuring that coffee beans are packaged correctly every time. This not only saves time and labor costs but also helps to streamline the packaging process, making it more efficient and cost-effective.

Overall, the benefits of using an automatic nitrogen gas flushing can seamer machine for coffee bean packaging are clear. From extending the shelf life of the product to preserving its quality and appearance, nitrogen gas flushing offers a range of advantages for coffee bean manufacturers and consumers alike. By investing in this technology, coffee bean producers can ensure that their products remain fresh, flavorful, and appealing to customers, ultimately leading to increased sales and customer satisfaction.

How to Choose the Right Automatic Nitrogen Gas Flushing Can Seamer Machine for Coffee Bean Production

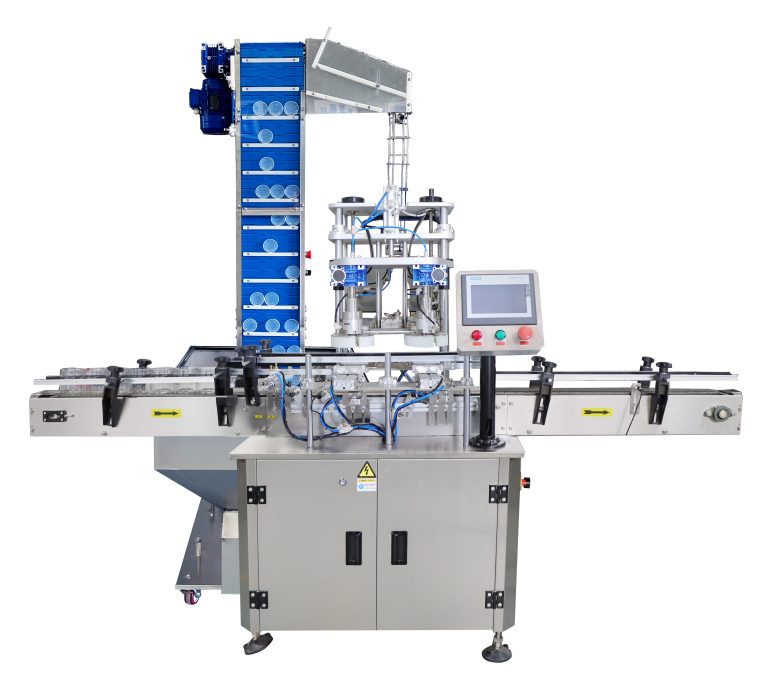

In the world of coffee production, ensuring the freshness and quality of the product is of utmost importance. One way to achieve this is through the use of automatic nitrogen gas flushing can seamer machines. These machines are designed to seal cans with nitrogen gas, which helps to preserve the flavor and aroma of the coffee beans. However, with so many options available on the market, choosing the right automatic nitrogen gas flushing can seamer machine for coffee bean production can be a daunting task.

When selecting a can seamer machine for coffee bean production, there are several factors to consider. One of the most important factors is the speed and efficiency of the machine. A high-speed machine can significantly increase production output, allowing for more cans to be sealed in a shorter amount of time. This is especially important in a fast-paced production environment where time is of the essence.

Another important factor to consider is the size and capacity of the machine. The size of the machine should be able to accommodate the volume of coffee beans being produced. It is important to choose a machine that can handle the workload without causing any bottlenecks in the production process. Additionally, the capacity of the machine should be sufficient to meet the demands of the production line.

In addition to speed and capacity, it is also important to consider the level of automation of the machine. An automatic nitrogen gas flushing can seamer machine that is fully automated can help to streamline the production process and reduce the need for manual labor. This can result in increased efficiency and productivity, as well as a reduction in human error.

Furthermore, it is important to consider the quality and reliability of the machine. A high-quality machine will be durable and long-lasting, reducing the need for frequent maintenance and repairs. It is important to choose a machine from a reputable manufacturer with a proven track record of producing reliable and high-quality equipment.

When choosing an automatic nitrogen gas flushing can seamer machine for coffee bean production, it is also important to consider the cost of the machine. While it is important to stay within budget, it is also important to consider the long-term benefits of investing in a high-quality machine. A cheaper machine may save money upfront, but it may end up costing more in the long run due to maintenance and repair costs.

In conclusion, choosing the right automatic nitrogen gas flushing can seamer machine for coffee bean production is a crucial decision that can have a significant impact on the quality and efficiency of the production process. By considering factors such as speed, capacity, automation, quality, reliability, and cost, you can make an informed decision that will benefit your coffee production operation in the long run.