Table of Contents

Benefits of Using Automatic Pure Juice Liquid Filling Machines in Your Factory

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of a factory. One way to achieve this is by investing in automatic pure juice liquid filling machines. These machines are designed to streamline the process of filling bottles with juice, eliminating the need for manual labor and reducing the risk of human error. In this article, we will explore the benefits of using automatic pure juice liquid filling machines in your factory.

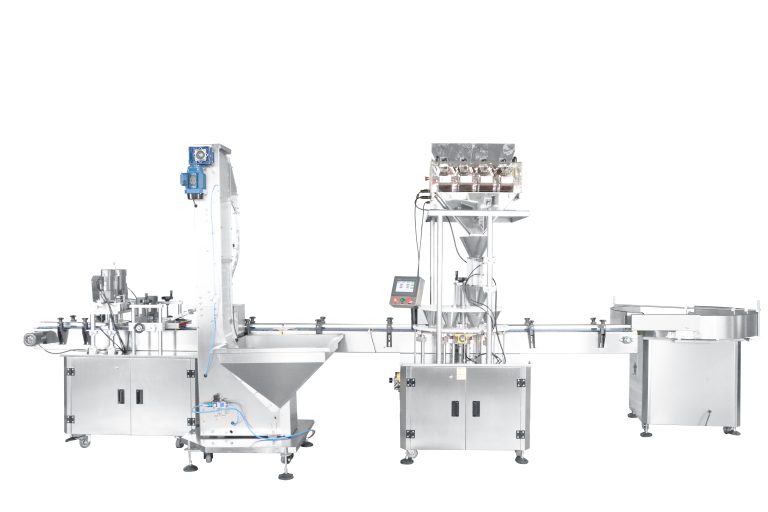

One of the main advantages of using automatic pure juice liquid filling machines is the increase in productivity. These machines are capable of filling a large number of bottles in a short amount of time, allowing your factory to meet high production demands. This can help to reduce bottlenecks in the production line and ensure that orders are fulfilled in a timely manner. Additionally, automatic filling machines are equipped with sensors and controls that can detect and correct any issues that may arise during the filling process, further increasing efficiency.

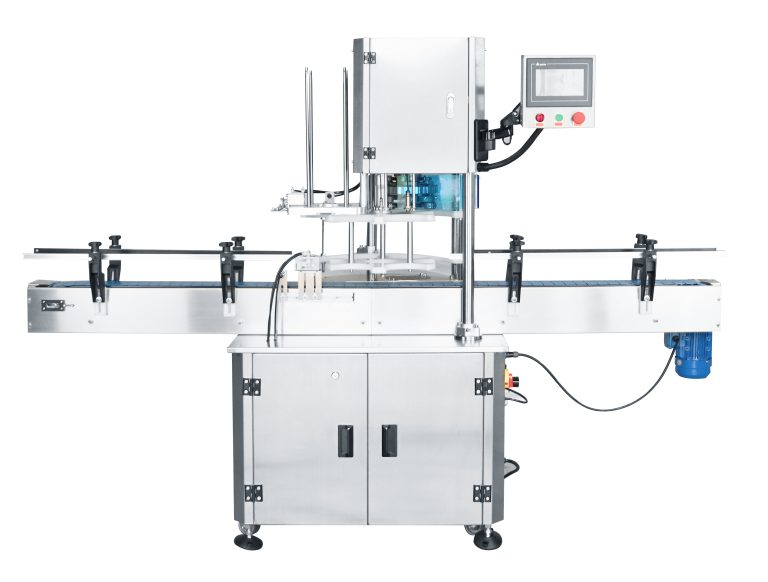

Another benefit of using automatic pure juice liquid filling machines is the consistency and accuracy they provide. Manual filling processes can be prone to errors, such as overfilling or underfilling bottles, which can result in product wastage and customer dissatisfaction. Automatic filling machines are programmed to dispense the exact amount of juice into each bottle, ensuring that every product meets the same high standard of quality. This level of consistency can help to build trust with customers and enhance the reputation of your brand.

In addition to improving productivity and accuracy, automatic pure juice liquid filling machines can also help to reduce operating costs. By automating the filling process, you can eliminate the need for manual labor, saving on labor costs and reducing the risk of injuries in the workplace. Furthermore, automatic filling machines are designed to be energy-efficient, helping to lower utility bills and minimize the environmental impact of your factory. Overall, investing in automatic filling machines can lead to significant cost savings in the long run.

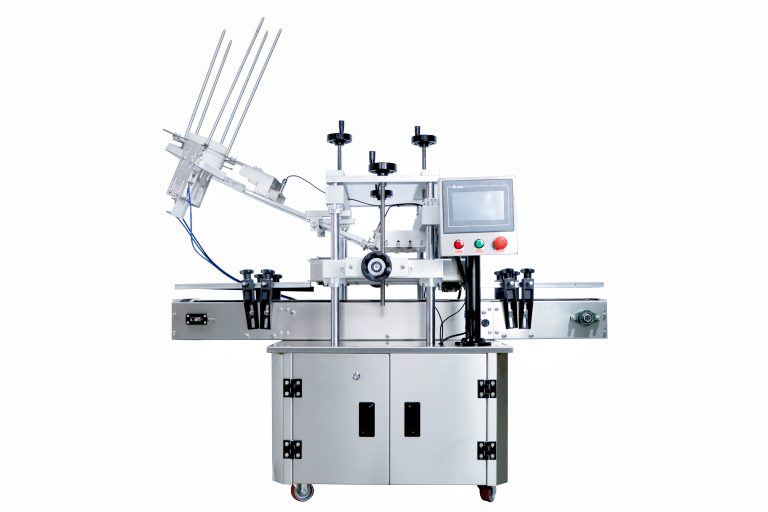

One of the key features of automatic pure juice liquid filling machines is their versatility. These machines can be easily adjusted to accommodate different bottle sizes and shapes, allowing you to fill a variety of products with ease. Whether you are filling small bottles for individual servings or large containers for bulk orders, automatic filling machines can handle the task efficiently. This flexibility can help to streamline your production process and adapt to changing market demands.

In conclusion, automatic pure juice liquid filling machines offer a wide range of benefits for factories looking to improve efficiency, accuracy, and cost-effectiveness. By investing in these machines, you can increase productivity, ensure consistency in product quality, reduce operating costs, and enhance the versatility of your production line. Overall, automatic filling machines can help to optimize the performance of your factory and drive success in the competitive manufacturing industry.

How to Choose the Right Automatic Pure Juice Liquid Filling Machine for Your Factory

When it comes to running a factory that produces pure juice, having the right equipment is essential to ensure efficiency and quality. One key piece of machinery that can greatly impact the production process is an automatic pure juice liquid filling machine. These machines are designed to accurately fill bottles with liquid product, reducing the risk of spillage and waste. However, with so many options available on the market, choosing the right automatic pure juice liquid filling machine for your factory can be a daunting task. In this article, we will discuss some important factors to consider when selecting a filling machine that meets your production needs.

First and foremost, it is crucial to assess the production capacity of your factory. Automatic pure juice liquid filling machines come in a variety of sizes and speeds, so it is important to choose a machine that can keep up with the demand of your production line. Consider factors such as the number of bottles you need to fill per hour, as well as the size and shape of the bottles. This will help you determine the appropriate filling speed and capacity required for your factory.

Another important factor to consider is the type of juice you will be filling. Some automatic pure juice liquid filling machines are specifically designed for filling certain types of liquids, such as thick or pulpy juices. Make sure to choose a machine that is compatible with the viscosity and consistency of your juice to ensure smooth and accurate filling. Additionally, consider any special requirements for filling, such as hot filling or aseptic filling, and choose a machine that can accommodate these needs.

In addition to production capacity and juice type, it is also important to consider the overall efficiency and reliability of the filling machine. Look for machines that are easy to operate and maintain, with user-friendly controls and minimal downtime. Consider the reputation of the manufacturer and read reviews from other customers to ensure that you are investing in a high-quality machine that will last for years to come.

Cost is another important factor to consider when choosing an automatic pure juice liquid filling machine for your factory. While it may be tempting to opt for the cheapest option available, it is important to consider the long-term costs associated with maintenance and repairs. Investing in a higher-quality machine may save you money in the long run by reducing downtime and increasing productivity.

Finally, consider the space available in your factory for the filling machine. Automatic pure juice liquid filling machines come in a variety of sizes, so make sure to choose a machine that fits comfortably in your production area. Consider factors such as the layout of your production line and any additional equipment that may be needed to support the filling machine.

In conclusion, choosing the right automatic pure juice liquid filling machine for your factory is a crucial decision that can greatly impact the efficiency and quality of your production process. By considering factors such as production capacity, juice type, efficiency, reliability, cost, and space requirements, you can select a filling machine that meets your specific needs and helps your factory run smoothly. Take the time to research and compare different options to ensure that you make the best investment for your business.