Benefits of Using Automatic Vacuum Glass Bottle Capping Equipment for Food Sauce

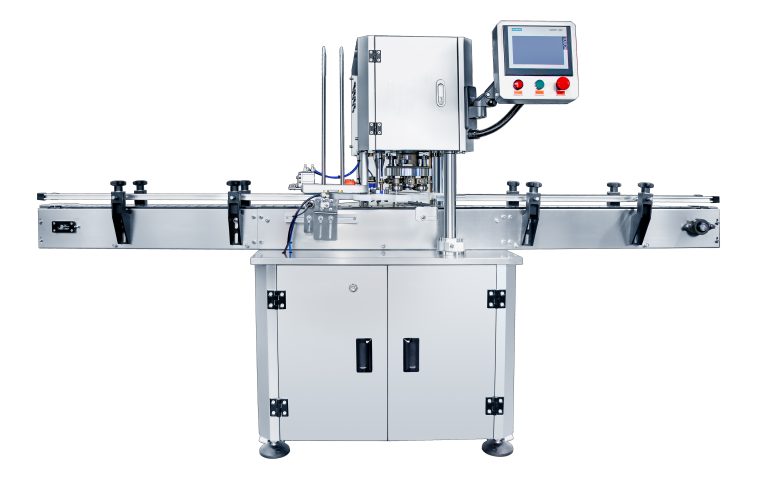

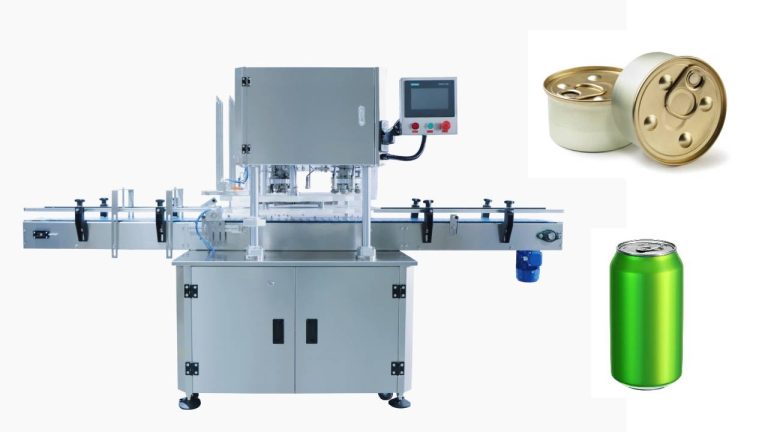

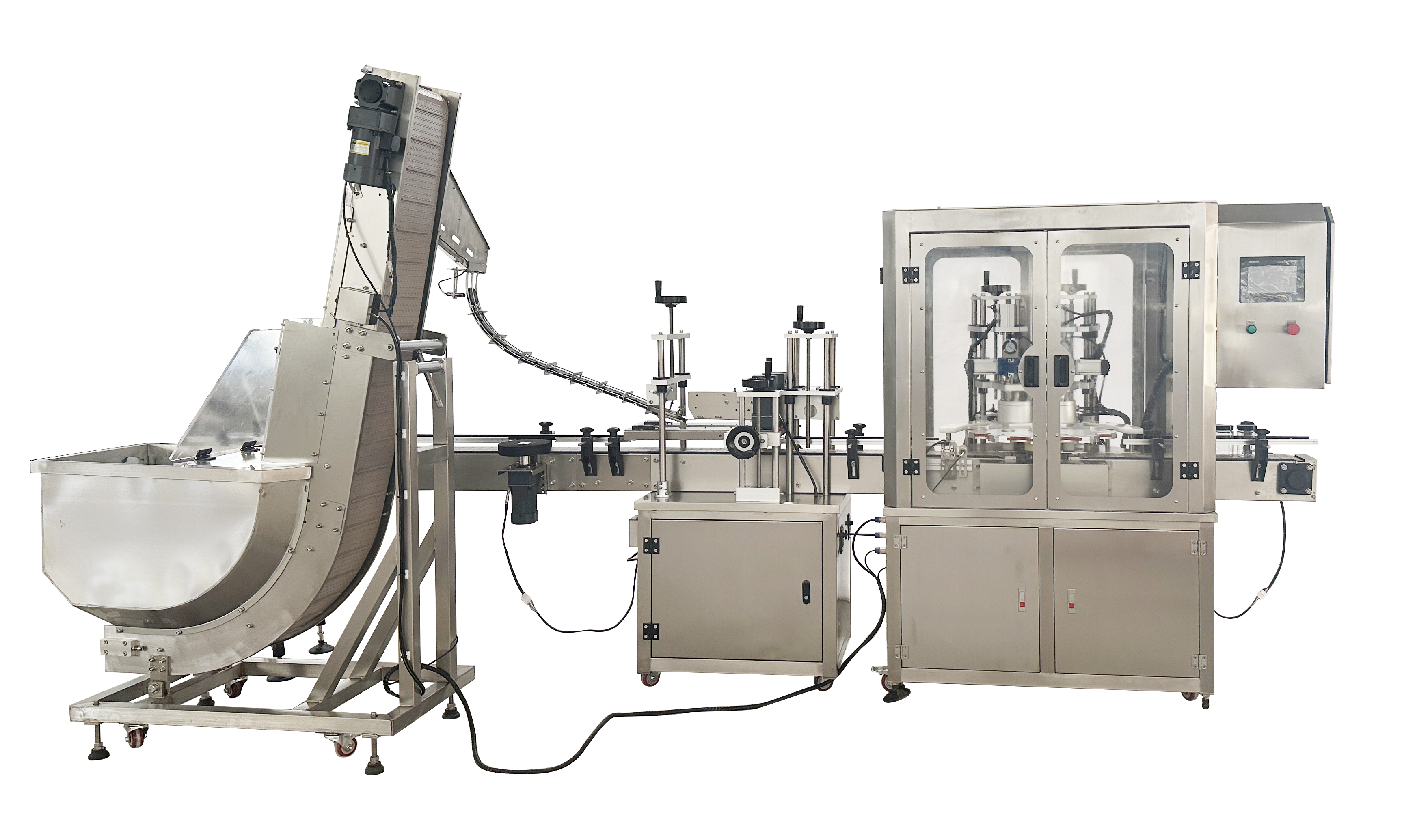

Automatic vacuum glass bottle capping equipment is a valuable tool for food sauce manufacturers looking to streamline their production process and ensure the quality and safety of their products. This innovative technology offers a range of benefits that can help businesses improve efficiency, reduce costs, and enhance the overall quality of their products.

One of the key benefits of using automatic vacuum glass bottle capping equipment is its ability to increase production speed. By automating the capping process, manufacturers can significantly reduce the time it takes to cap each bottle, allowing them to produce more bottles in less time. This can help businesses meet increasing demand and improve their overall productivity.

In addition to increasing production speed, automatic vacuum glass bottle capping equipment can also help businesses reduce labor costs. By automating the capping process, manufacturers can eliminate the need for manual labor, freeing up employees to focus on other tasks. This can help businesses save money on labor costs and improve their overall efficiency.

Another benefit of using automatic vacuum glass bottle capping equipment is its ability to improve the quality and consistency of capping. Manual capping can be prone to human error, resulting in uneven or improperly sealed bottles. Automatic capping equipment, on the other hand, is designed to ensure a consistent and secure seal on every bottle, reducing the risk of leaks or contamination.

Furthermore, automatic vacuum glass bottle capping equipment can help businesses improve the safety of their products. By ensuring a secure seal on every bottle, manufacturers can reduce the risk of contamination and spoilage, helping to protect the health and safety of consumers. This can also help businesses maintain a positive reputation and build trust with their customers.

In addition to these benefits, automatic vacuum glass bottle capping equipment can also help businesses reduce waste and improve sustainability. By ensuring a secure seal on every bottle, manufacturers can reduce the risk of product spoilage and waste, helping to minimize their environmental impact. This can also help businesses save money on wasted product and improve their overall sustainability efforts.

Overall, automatic vacuum glass bottle capping equipment offers a range of benefits for food sauce manufacturers looking to improve their production process. From increasing production speed and reducing labor costs to improving product quality and safety, this innovative technology can help businesses streamline their operations and enhance the overall quality of their products. By investing in automatic capping equipment, manufacturers can improve efficiency, reduce costs, and ensure the success of their business in the competitive food sauce market.