Table of Contents

Benefits of Using Beverage Can Seaming Machine for Aluminum Cans

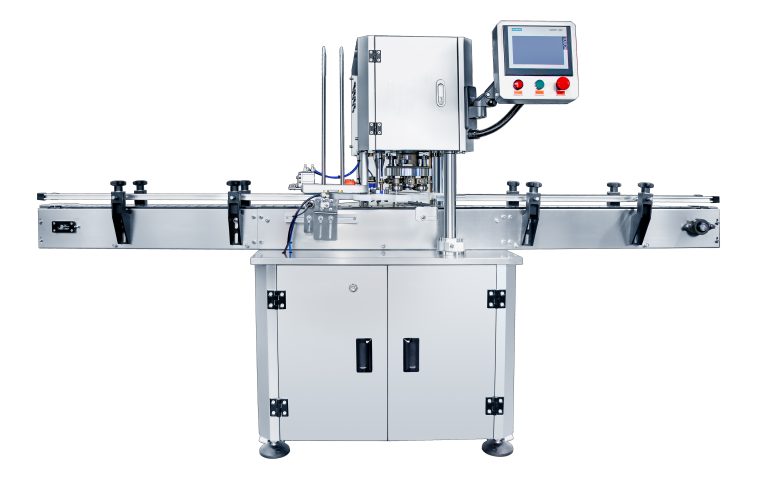

Beverage can seaming machines are essential equipment in the beverage industry for sealing aluminum cans. These machines play a crucial role in ensuring the quality and safety of canned beverages. There are several benefits to using a beverage can seaming machine for aluminum cans, which we will explore in this article.

One of the primary benefits of using a beverage can seaming machine is the consistency and precision it provides in sealing aluminum cans. These machines are designed to apply the perfect amount of pressure to seal the cans effectively, preventing leaks and contamination. This level of precision is crucial for maintaining the quality and integrity of the product inside the can.

In addition to consistency, beverage can seaming machines also offer efficiency in the production process. These machines are capable of sealing hundreds of cans per minute, significantly increasing the production output compared to manual sealing methods. This increased efficiency not only saves time but also reduces labor costs, making it a cost-effective solution for beverage manufacturers.

Furthermore, beverage can seaming machines are designed to handle a wide range of can sizes and shapes, making them versatile and adaptable to different production needs. Whether you are packaging standard 12-ounce cans or specialty cans with unique shapes, a beverage can seaming machine can accommodate various can sizes and configurations, providing flexibility in production.

Another benefit of using a beverage can seaming machine is the improved safety and hygiene it offers. These machines are equipped with features that ensure the cans are sealed properly, reducing the risk of contamination and spoilage. By sealing the cans hermetically, beverage can seaming machines help preserve the freshness and quality of the product, extending its shelf life and ensuring consumer satisfaction.

Additionally, beverage can seaming machines are designed for easy operation and maintenance, making them user-friendly and cost-effective in the long run. With minimal training, operators can learn how to operate the machine efficiently, reducing the risk of errors and downtime. Regular maintenance and servicing of the machine can also prolong its lifespan and ensure optimal performance, further enhancing its value for beverage manufacturers.

Overall, the benefits of using a beverage can seaming machine for aluminum cans are numerous and significant. From consistency and precision in sealing to efficiency and versatility in production, these machines offer a range of advantages that can improve the quality, safety, and efficiency of beverage packaging. With the increasing demand for canned beverages, investing in a beverage can seaming machine is a wise decision for beverage manufacturers looking to enhance their production capabilities and meet consumer expectations.

How to Choose the Right Beverage Can Seaming Machine for Aluminum Cans

When it comes to choosing the right beverage can seaming machine for aluminum cans, there are several factors to consider. The seaming process is crucial in ensuring that the cans are properly sealed to maintain the freshness and quality of the beverage inside. With the increasing demand for canned beverages, it is important to invest in a high-quality seaming machine that can meet the production needs of your business.

One of the first things to consider when choosing a beverage can seaming machine for aluminum cans is the size and speed of the machine. The size of the machine will depend on the volume of production you require. If you have a high production volume, you will need a larger machine that can handle a higher number of cans per minute. On the other hand, if you have a smaller production volume, a smaller machine may be sufficient.

In addition to size, the speed of the machine is also an important factor to consider. A faster machine will be able to seam more cans in a shorter amount of time, increasing your overall production efficiency. However, it is important to balance speed with quality to ensure that the cans are properly sealed without any defects.

Another important factor to consider when choosing a beverage can seaming machine is the type of seaming technology used. There are two main types of seaming technology: rotary and reciprocating. Rotary seaming machines are more commonly used for aluminum cans and offer a higher level of precision and consistency in the seaming process. Reciprocating seaming machines, on the other hand, are more versatile and can be used for a variety of can sizes and materials.

When choosing a seaming machine, it is important to consider the maintenance and support services offered by the manufacturer. A reliable manufacturer will provide regular maintenance services to ensure that the machine is running smoothly and efficiently. Additionally, they should offer technical support in case of any issues or malfunctions with the machine.

Cost is also an important factor to consider when choosing a beverage can seaming machine for aluminum cans. While it is important to invest in a high-quality machine, it is also important to consider your budget and choose a machine that offers the best value for your money. Compare prices from different manufacturers and consider the long-term costs of maintenance and operation.

In conclusion, choosing the right beverage can seaming machine for aluminum cans is crucial in ensuring the quality and efficiency of your production process. Consider factors such as size, speed, seaming technology, maintenance and support services, and cost when making your decision. By investing in a high-quality seaming machine, you can ensure that your canned beverages are properly sealed and maintain their freshness and quality.