Table of Contents

Benefits of Using Big Size Metal Can Sealing Machine for Industrial Packaging

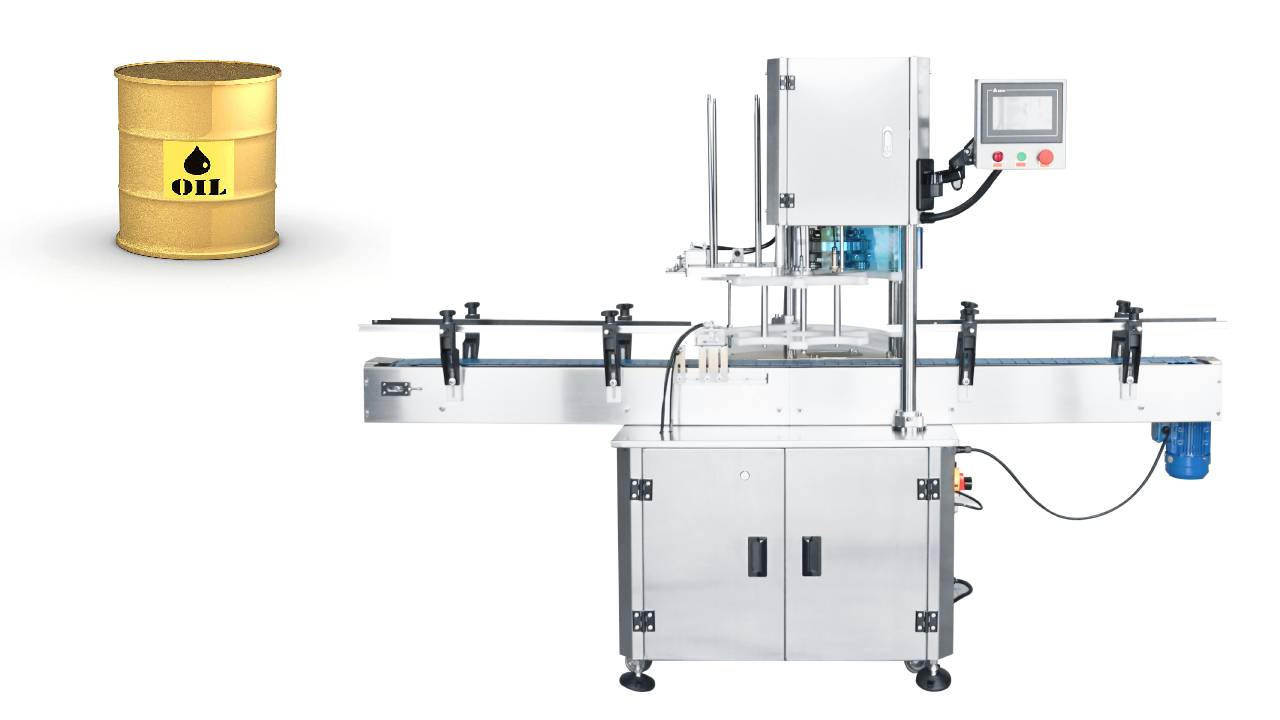

In the world of industrial packaging, efficiency and reliability are key factors in ensuring that products are securely sealed and protected during transportation and storage. One essential piece of equipment that plays a crucial role in this process is the big size metal can sealing machine. These machines are designed to seal large metal cans quickly and effectively, providing a tight seal that helps to preserve the contents inside.

One of the primary benefits of using a big size metal can sealing machine is the speed at which it can seal cans. These machines are capable of sealing hundreds of cans per hour, making them ideal for high-volume production environments. This increased speed not only helps to improve overall productivity but also ensures that products are sealed and ready for distribution in a timely manner.

In addition to speed, big size metal can sealing machines also offer a high level of precision and consistency in the sealing process. The machines are designed to apply a uniform amount of pressure to each can, ensuring that the seal is tight and secure every time. This level of precision helps to reduce the risk of leaks or contamination, which can be costly and damaging to a company’s reputation.

Another key benefit of using a big size metal can sealing machine is the durability and reliability of the seals that it produces. These machines are built to withstand the rigors of industrial production, ensuring that they can continue to operate effectively even in demanding environments. The seals created by these machines are strong and secure, providing a barrier that helps to protect the contents of the cans from external elements.

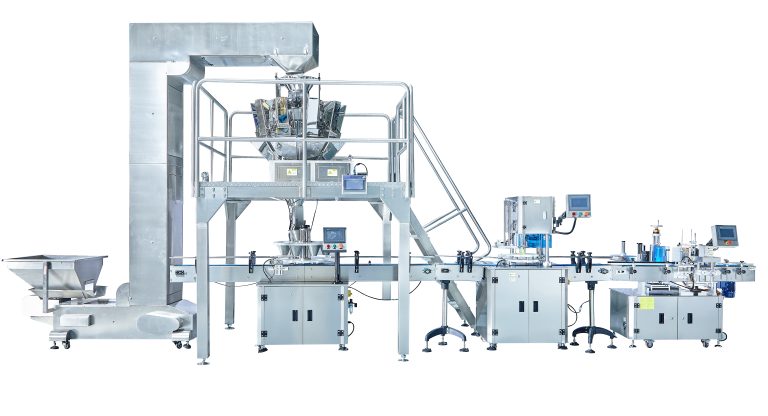

Furthermore, big size metal can sealing machines are versatile and can be used to seal a wide range of can sizes and shapes. This flexibility makes them suitable for a variety of packaging applications, allowing companies to use them for different products without the need for multiple machines. This versatility helps to streamline production processes and reduce costs associated with purchasing and maintaining multiple pieces of equipment.

In conclusion, the benefits of using a big size metal can sealing machine for industrial packaging are clear. These machines offer speed, precision, durability, and versatility, making them an essential tool for companies looking to improve their packaging processes. By investing in a high-quality sealing machine, companies can ensure that their products are securely sealed and protected, helping to maintain product quality and customer satisfaction. With the right equipment in place, companies can streamline their production processes and improve overall efficiency, ultimately leading to increased profitability and success in the competitive industrial packaging market.

How to Choose the Right Big Size Metal Can Sealing Machine for Your Production Line

When it comes to choosing the right big size metal can sealing machine for your production line, there are several factors to consider. From the size and speed of the machine to the type of cans it can seal, making the right choice is crucial to ensuring the efficiency and effectiveness of your production process.

One of the first things to consider when selecting a big size metal can sealing machine is the size of the cans you will be sealing. Different machines are designed to handle different sizes of cans, so it is important to choose a machine that can accommodate the cans you will be using in your production line. Additionally, you will want to consider the speed at which the machine can seal cans. If you have a high-volume production line, you will need a machine that can keep up with the demand.

Another important factor to consider when choosing a big size metal can sealing machine is the type of cans it can seal. Some machines are designed to seal specific types of cans, such as aluminum or tin cans, while others are more versatile and can seal a variety of can sizes and materials. It is important to choose a machine that is compatible with the cans you will be using in your production line to ensure a seamless sealing process.

In addition to considering the size, speed, and compatibility of the machine, you will also want to think about the features and capabilities of the machine. Some big size metal can sealing machines come equipped with additional features, such as automatic lid feeding and sealing, adjustable sealing pressure, and easy-to-use controls. These features can help streamline the sealing process and improve efficiency in your production line.

When choosing a big size metal can sealing machine, it is also important to consider the reputation and reliability of the manufacturer. Look for a manufacturer with a proven track record of producing high-quality machines that are built to last. Reading reviews and testimonials from other customers can also help you gauge the quality and performance of a particular machine.

Ultimately, choosing the right big size metal can sealing machine for your production line is a decision that should not be taken lightly. By considering factors such as size, speed, compatibility, features, and manufacturer reputation, you can ensure that you select a machine that meets your production needs and helps you achieve your production goals.

In conclusion, selecting the right big size metal can sealing machine is essential to the success of your production line. By carefully considering factors such as size, speed, compatibility, features, and manufacturer reputation, you can choose a machine that will help streamline your sealing process and improve efficiency in your production line. With the right machine in place, you can ensure that your cans are sealed quickly and effectively, allowing you to meet the demands of your customers and grow your business.