Table of Contents

Benefits of Using a Bottle Capping Machine for Spray Bottles

A bottle capping machine is a valuable tool for businesses that need to cap a large number of bottles quickly and efficiently. When it comes to spray bottles, a bottle capping machine can offer numerous benefits that can help streamline the production process and improve overall efficiency.

One of the key benefits of using a bottle capping machine for spray bottles is speed. Manual capping can be a time-consuming process, especially when dealing with a large volume of bottles. A bottle capping machine can cap bottles at a much faster rate, helping to increase productivity and reduce bottlenecks in the production line.

In addition to speed, a bottle capping machine can also help improve the consistency and accuracy of the capping process. Manual capping can lead to inconsistencies in the tightness of the caps, which can affect the quality of the final product. A bottle capping machine ensures that each bottle is capped with the same level of tightness, resulting in a more uniform and professional-looking finished product.

Furthermore, using a bottle capping machine for spray bottles can help reduce the risk of contamination. Manual capping can expose the bottles to contaminants from the environment or from the hands of the workers. A bottle capping machine can cap the bottles in a controlled and sterile environment, minimizing the risk of contamination and ensuring the integrity of the product.

Another benefit of using a bottle capping machine for spray bottles is the reduction of labor costs. Manual capping requires a significant amount of labor, which can be costly for businesses. By automating the capping process with a bottle capping machine, businesses can reduce the need for manual labor and reallocate resources to other areas of the production process.

Additionally, a bottle capping machine can help improve worker safety. Manual capping can be a repetitive and physically demanding task, which can lead to injuries and strain on the workers. A bottle capping machine can take over this task, reducing the risk of injuries and creating a safer work environment for employees.

Furthermore, using a bottle capping machine for spray bottles can help businesses meet regulatory requirements and quality standards. Consistent and accurate capping is essential for ensuring that the product meets the required specifications and maintains its quality during storage and transportation. A bottle capping machine can help businesses achieve this level of consistency and accuracy, ensuring that their products meet the necessary standards.

In conclusion, using a bottle capping machine for spray bottles offers numerous benefits for businesses looking to improve their production process. From increased speed and efficiency to improved consistency and accuracy, a bottle capping machine can help businesses streamline their operations and produce high-quality products. By investing in a bottle capping machine, businesses can save time and money, improve worker safety, and ensure that their products meet regulatory requirements and quality standards.

How to Choose the Right Bottle Capping Machine for Your Spray Bottle Products

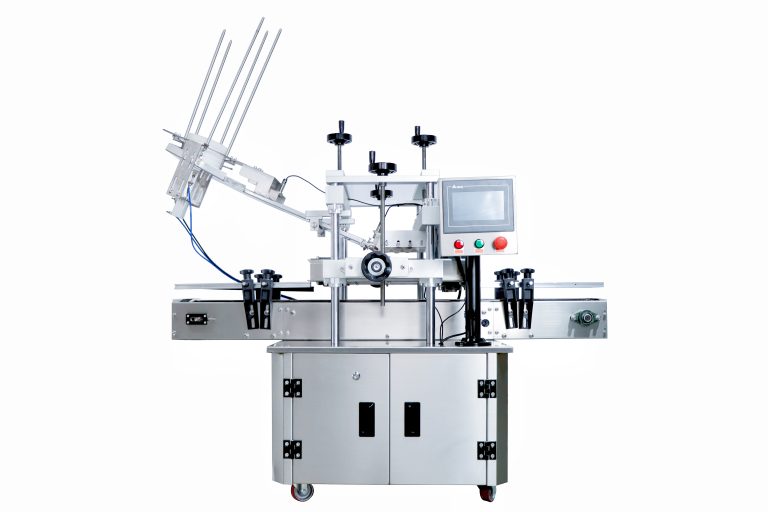

When it comes to packaging products in spray bottles, having the right bottle capping machine is essential. A bottle capping machine is a piece of equipment that is used to securely seal bottles with caps, ensuring that the contents remain fresh and protected. With a wide range of bottle capping machines available on the market, choosing the right one for your spray bottle products can be a daunting task. In this article, we will discuss some key factors to consider when selecting a bottle capping machine for your spray bottle products.

One of the first things to consider when choosing a bottle capping machine is the type of caps that will be used on your spray bottles. Different bottle capping machines are designed to work with specific types of caps, so it is important to ensure that the machine you choose is compatible with the caps you will be using. Whether you are using screw caps, snap-on caps, or trigger caps, there is a bottle capping machine available to meet your needs.

Another important factor to consider when selecting a bottle capping machine is the speed at which it can cap bottles. The production requirements of your spray bottle products will determine the speed at which you need the machine to operate. Some bottle capping machines are capable of capping hundreds of bottles per minute, while others may only be able to cap a few dozen bottles per minute. It is important to choose a machine that can keep up with the demands of your production line to ensure efficiency and productivity.

In addition to speed, the accuracy of the bottle capping machine is also crucial. A machine that consistently applies caps securely and evenly will help to prevent leaks and ensure that your products are properly sealed. Look for a bottle capping machine that offers precise control over the capping process to ensure that each bottle is sealed correctly every time.

When selecting a bottle capping machine for your spray bottle products, it is also important to consider the size and shape of the bottles that will be capped. Some machines are designed to work with specific bottle sizes and shapes, so it is important to choose a machine that is compatible with the bottles you will be using. Whether you are capping round bottles, square bottles, or uniquely shaped bottles, there is a bottle capping machine available to meet your needs.

Finally, it is important to consider the overall quality and reliability of the bottle capping machine. Investing in a high-quality machine from a reputable manufacturer will help to ensure that your capping process runs smoothly and efficiently. Look for a machine that is built to last and that comes with a warranty to protect your investment.

In conclusion, choosing the right bottle capping machine for your spray bottle products is essential to ensuring that your products are properly sealed and protected. Consider factors such as the type of caps, speed, accuracy, bottle size and shape, and overall quality when selecting a bottle capping machine. By taking the time to carefully evaluate your needs and choose a machine that meets them, you can ensure that your capping process is efficient and effective.

Maintenance Tips for Ensuring the Longevity of Your Bottle Capping Machine

Bottle capping machines are essential equipment for businesses that rely on efficient packaging processes. Whether you are in the pharmaceutical, food and beverage, or cosmetic industry, having a reliable bottle capping machine is crucial for ensuring the quality and integrity of your products. To maximize the longevity of your bottle capping machine and avoid costly repairs or replacements, it is important to implement regular maintenance practices.

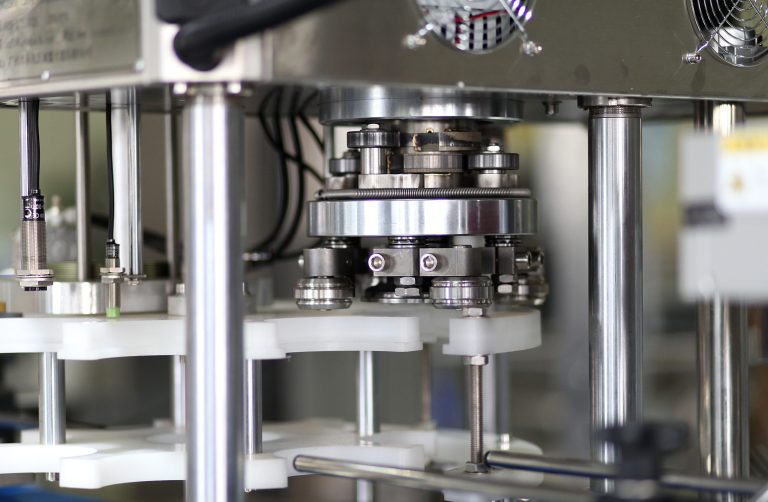

One of the key maintenance tips for ensuring the longevity of your bottle capping machine is to regularly clean and lubricate the moving parts. Over time, dust, debris, and residue from the bottles can accumulate on the machine, causing it to operate less efficiently. By cleaning the machine regularly with a mild detergent and lubricating the moving parts with a suitable lubricant, you can prevent wear and tear and extend the lifespan of your equipment.

In addition to cleaning and lubricating the machine, it is important to inspect the machine for any signs of wear or damage. Check the belts, chains, and other components for any signs of wear and tear, and replace them as needed. By addressing any issues early on, you can prevent further damage to the machine and avoid costly repairs down the line.

Another important maintenance tip for ensuring the longevity of your bottle capping machine is to calibrate the machine regularly. Over time, the settings on the machine may drift, leading to inconsistent capping results. By calibrating the machine regularly according to the manufacturer’s specifications, you can ensure that the machine is operating at its optimal performance and producing consistent capping results.

Furthermore, it is important to train your staff on how to operate the bottle capping machine properly. Improper operation of the machine can lead to premature wear and damage, reducing the lifespan of the equipment. Make sure that your staff are trained on how to use the machine safely and efficiently, and provide ongoing training and support to ensure that they are using the machine correctly.

Lastly, it is important to schedule regular maintenance checks with a qualified technician. A professional technician can inspect the machine thoroughly, identify any potential issues, and perform any necessary repairs or adjustments. By investing in regular maintenance checks, you can prevent costly breakdowns and ensure that your bottle capping machine continues to operate smoothly for years to come.

In conclusion, maintaining the longevity of your bottle capping machine requires regular cleaning, lubrication, inspection, calibration, proper operation, and professional maintenance checks. By implementing these maintenance tips, you can extend the lifespan of your equipment, reduce downtime, and ensure the quality and integrity of your products. Remember that a well-maintained bottle capping machine is essential for the success of your business, so make sure to prioritize maintenance and care for your equipment.