Table of Contents

Benefits of Using a Can Sealing Machine for Food Preservation

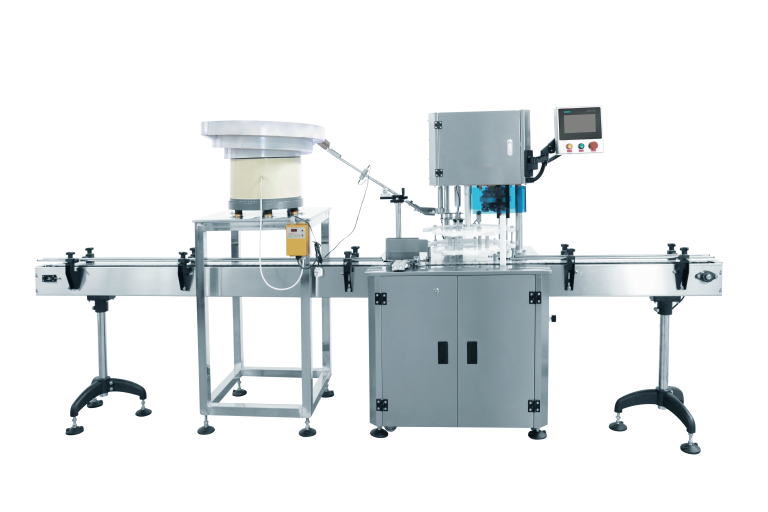

Food preservation is a crucial aspect of the food industry, ensuring that products remain fresh and safe for consumption over an extended period of time. One of the most effective methods of food preservation is canning, which involves sealing food in airtight containers to prevent spoilage. Can sealing machines are essential tools in the canning process, providing a reliable and efficient way to seal cans of various sizes and materials.

One of the primary benefits of using a can sealing machine for food preservation is the ability to seal cans of all kinds. Whether you are working with tin cans, aluminum cans, or even plastic containers, a can sealing machine can accommodate a wide range of materials. This versatility makes it easier for food manufacturers to package their products in the most suitable containers, ensuring that the food remains fresh and safe for consumption.

In addition to sealing cans of different materials, can sealing machines also come in various sizes to accommodate different can sizes. This flexibility allows food manufacturers to seal cans of all shapes and sizes, from small individual portions to large bulk containers. By using a can sealing machine that can handle a variety of can sizes, food manufacturers can streamline their production process and meet the diverse needs of their customers.

Another benefit of using a can sealing machine for food preservation is the speed and efficiency it offers. Manual sealing of cans can be a time-consuming and labor-intensive process, requiring skilled workers to ensure a proper seal. Can sealing machines automate the sealing process, allowing for faster production and consistent results. This increased efficiency not only saves time and labor costs but also ensures that the food is sealed properly to prevent spoilage.

Furthermore, can sealing machines provide a more secure seal than manual sealing methods. The automated process of a can sealing machine ensures that the cans are sealed tightly and securely, reducing the risk of contamination and spoilage. This level of security is essential for food manufacturers who need to maintain the quality and safety of their products throughout the distribution process.

In addition to the benefits of speed, efficiency, and security, can sealing machines also offer a cost-effective solution for food preservation. While the initial investment in a can sealing machine may be higher than manual sealing methods, the long-term savings in labor costs and reduced spoilage make it a worthwhile investment for food manufacturers. By using a can sealing machine, food manufacturers can increase their production capacity and reduce waste, ultimately improving their bottom line.

-scaled.jpg)

Overall, the benefits of using a can sealing machine for food preservation are clear. From sealing cans of all kinds to increasing efficiency and reducing costs, can sealing machines offer a reliable and effective solution for food manufacturers looking to preserve their products. By investing in a can sealing machine, food manufacturers can ensure that their products remain fresh and safe for consumption, meeting the needs of their customers and maintaining the quality of their brand.

How to Choose the Right Can Sealing Machine for Your Business

When it comes to packaging products in cans, having the right can sealing machine is essential for ensuring a secure and airtight seal. With so many different types of can sealing machines on the market, choosing the right one for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting a can sealing machine that is suitable for all kinds of cans.

One of the first things to consider when choosing a can sealing machine is the type of cans you will be sealing. Different can sealing machines are designed to work with specific types and sizes of cans, so it is important to choose a machine that is compatible with the cans you will be using. Whether you are sealing aluminum cans, tin cans, or plastic cans, there is a can sealing machine available to meet your needs.

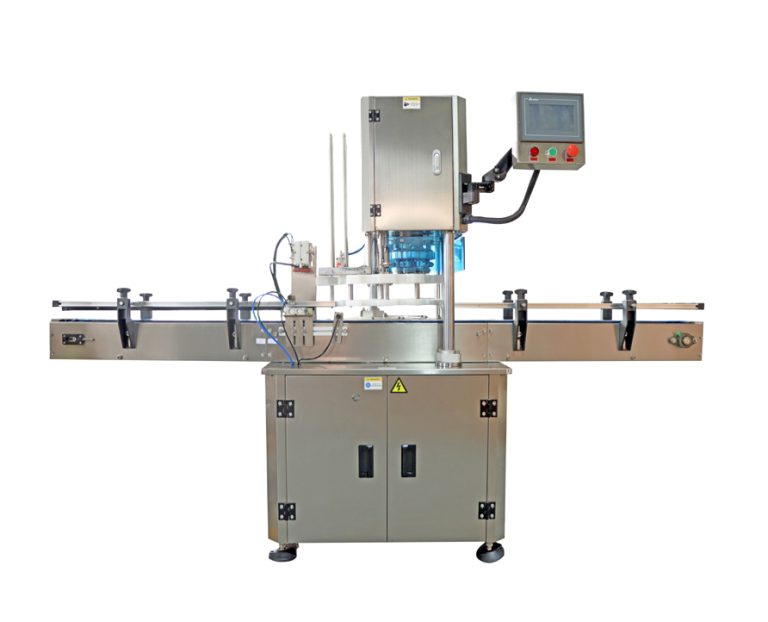

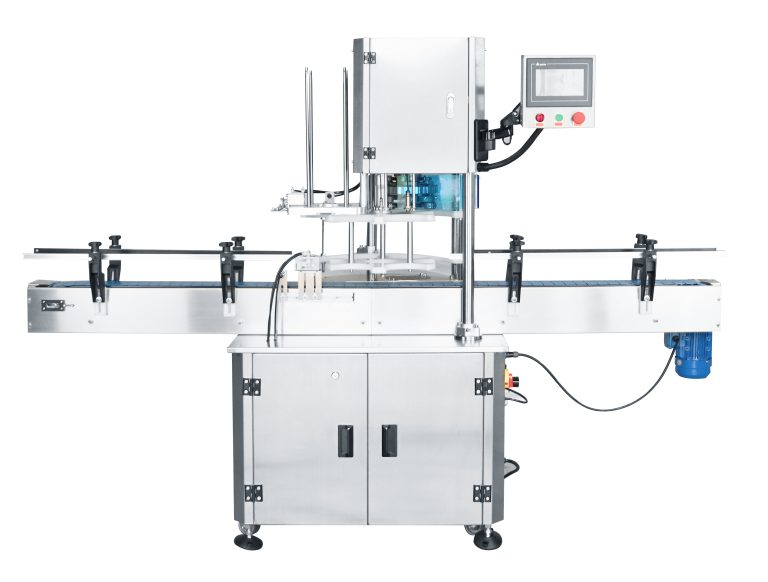

Another important factor to consider when selecting a can sealing machine is the speed and efficiency of the machine. If you have a high volume of cans to seal, you will want a machine that can seal cans quickly and efficiently to keep up with demand. Look for a can sealing machine that has a high sealing speed and can handle a large number of cans per hour to ensure that your production process runs smoothly.

In addition to speed and compatibility, it is also important to consider the sealing method used by the can sealing machine. There are several different sealing methods available, including induction sealing, vacuum sealing, and pressure sealing. Each sealing method has its own advantages and disadvantages, so it is important to choose a machine that uses a sealing method that is best suited to your specific needs.

When choosing a can sealing machine, it is also important to consider the size and space requirements of the machine. Make sure that the machine will fit comfortably in your production space and that you have enough room to operate the machine safely and efficiently. Additionally, consider the power requirements of the machine and make sure that you have the necessary electrical outlets and power supply to operate the machine effectively.

Finally, when selecting a can sealing machine, it is important to consider the cost of the machine and your budget. Can sealing machines can vary widely in price, so it is important to choose a machine that fits within your budget while still meeting your needs for speed, efficiency, and compatibility. Consider the long-term costs of operating the machine, including maintenance and repair costs, to ensure that you are making a sound investment for your business.

In conclusion, choosing the right can sealing machine for your business is essential for ensuring that your products are sealed securely and efficiently. Consider factors such as compatibility, speed, sealing method, size and space requirements, and cost when selecting a can sealing machine to meet your specific needs. With the right can sealing machine, you can streamline your production process and ensure that your products are sealed to perfection every time.