Benefits of Using a Coconut Beverage Can Filler and Sealer Machine Line

Coconut beverages have become increasingly popular in recent years due to their health benefits and unique flavor profile. As demand for these products continues to rise, manufacturers are constantly looking for ways to streamline their production processes and increase efficiency. One such solution is the use of a coconut beverage can filler and sealer machine line.

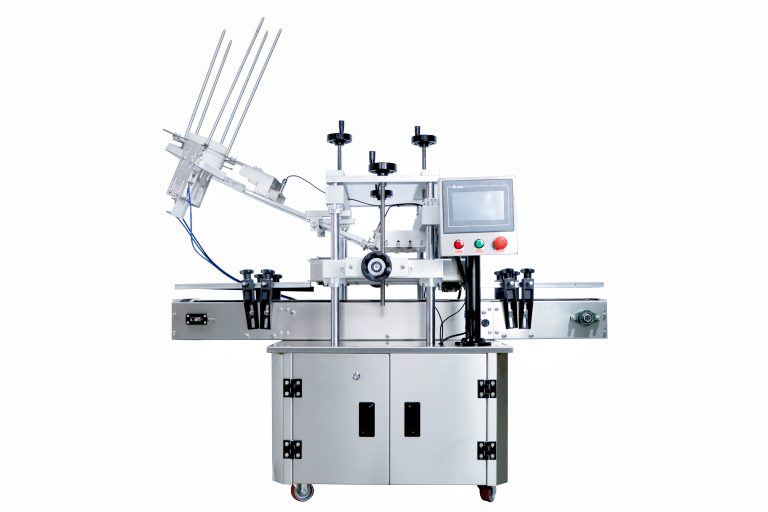

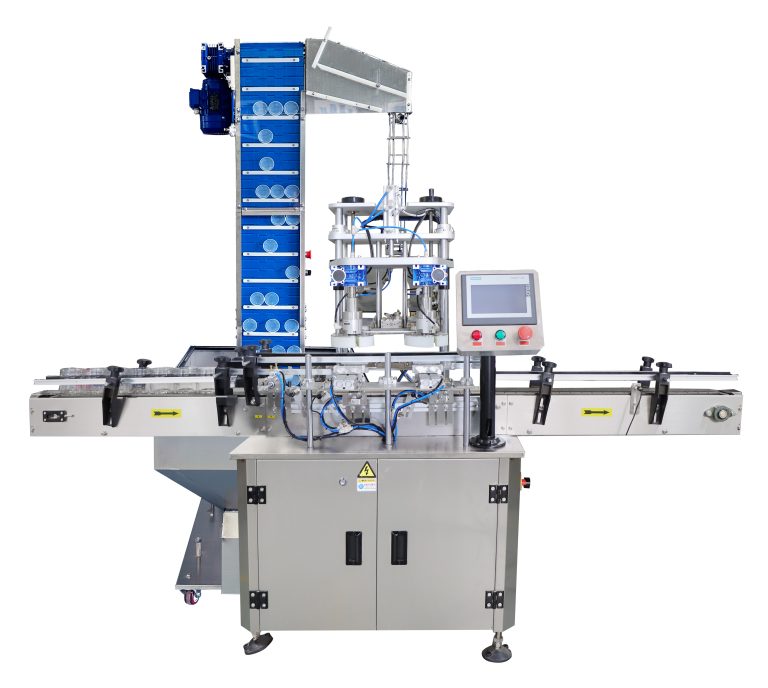

These machines are specifically designed to fill and seal cans with coconut beverages quickly and accurately. They are equipped with advanced technology that ensures precise filling levels and airtight seals, resulting in a high-quality finished product. By investing in a coconut beverage can filler and sealer machine line, manufacturers can enjoy a wide range of benefits that can help improve their overall production process.

One of the key benefits of using a coconut beverage can filler and sealer machine line is increased efficiency. These machines are capable of filling and sealing hundreds of cans per minute, far surpassing the capabilities of manual labor. This means that manufacturers can significantly increase their production output without sacrificing quality. Additionally, the automated nature of these machines reduces the risk of human error, resulting in a more consistent and reliable finished product.

Another benefit of using a coconut beverage can filler and sealer machine line is improved product quality. These machines are designed to fill cans with precision, ensuring that each can contains the correct amount of product. Additionally, the airtight seals created by the sealing machine help to preserve the freshness and flavor of the coconut beverage, extending its shelf life and enhancing its overall quality. This can help manufacturers maintain customer satisfaction and loyalty, ultimately leading to increased sales and profitability.

In addition to increased efficiency and improved product quality, using a coconut beverage can filler and sealer machine line can also help manufacturers reduce costs. By automating the filling and sealing process, manufacturers can eliminate the need for manual labor, reducing labor costs and increasing overall productivity. Additionally, the precise filling levels achieved by these machines can help minimize product waste, further reducing costs and increasing profitability.

Furthermore, investing in a coconut beverage can filler and sealer machine line can also help manufacturers meet the growing demand for their products. As consumer interest in coconut beverages continues to rise, manufacturers need to be able to scale up their production quickly and efficiently. These machines allow manufacturers to increase their production output without compromising on quality, enabling them to meet the demands of their customers and capitalize on market opportunities.

Overall, the benefits of using a coconut beverage can filler and sealer machine line are clear. From increased efficiency and improved product quality to reduced costs and scalability, these machines offer a wide range of advantages that can help manufacturers streamline their production processes and stay competitive in the market. By investing in this technology, manufacturers can position themselves for success in the growing coconut beverage industry.

-768x622.jpg)

-768x622.jpg)