Table of Contents

Benefits of Using Coconut Oil in Automatic Tin Can Seaming Machines

Coconut oil has gained popularity in recent years for its numerous health benefits and versatile uses. From cooking to skincare, this natural oil has become a staple in many households. One of the lesser-known uses of coconut oil is in automatic tin can seaming machines. These machines are used to seal tin cans, ensuring that the contents remain fresh and free from contamination. By using coconut oil in these machines, manufacturers can enjoy a range of benefits that contribute to the overall quality of their products.

One of the main benefits of using coconut oil in automatic tin can seaming machines is its natural antimicrobial properties. Coconut oil contains lauric acid, a fatty acid that has been shown to have antimicrobial and antifungal properties. When used in tin can seaming machines, coconut oil can help prevent the growth of harmful bacteria and fungi that can contaminate the contents of the cans. This can help extend the shelf life of the products and ensure that they remain safe for consumption.

In addition to its antimicrobial properties, coconut oil is also a natural lubricant. When used in tin can seaming machines, coconut oil can help reduce friction between the moving parts, allowing the machine to operate smoothly and efficiently. This can help prevent wear and tear on the machine, reducing the need for maintenance and repairs. By using coconut oil as a lubricant, manufacturers can also ensure that their tin can seaming machines operate at optimal levels, producing high-quality sealed cans consistently.

Furthermore, coconut oil is a renewable and sustainable resource. Unlike petroleum-based lubricants, which are derived from non-renewable sources, coconut oil is extracted from the kernels of coconuts, which are abundant in tropical regions. By using coconut oil in automatic tin can seaming machines, manufacturers can reduce their environmental impact and contribute to a more sustainable future. This can help improve the overall sustainability of the manufacturing process and align with consumers’ growing preference for eco-friendly products.

Another benefit of using coconut oil in automatic tin can seaming machines is its high heat resistance. Coconut oil has a high smoke point, making it ideal for use in high-temperature applications such as sealing tin cans. This can help prevent the oil from breaking down and forming harmful compounds when exposed to heat, ensuring that the sealed cans remain safe for consumption. By using coconut oil in tin can seaming machines, manufacturers can ensure that their products meet the highest safety standards and provide consumers with peace of mind.

In conclusion, the benefits of using coconut oil in automatic tin can seaming machines are numerous. From its natural antimicrobial properties to its renewable and sustainable nature, coconut oil offers a range of advantages that can improve the quality and efficiency of the manufacturing process. By incorporating coconut oil into tin can seaming machines, manufacturers can enjoy a more sustainable, efficient, and safe production process, ultimately leading to higher-quality products for consumers.

How to Choose the Right Automatic Tin Can Seaming Machine for Coconut Oil Production

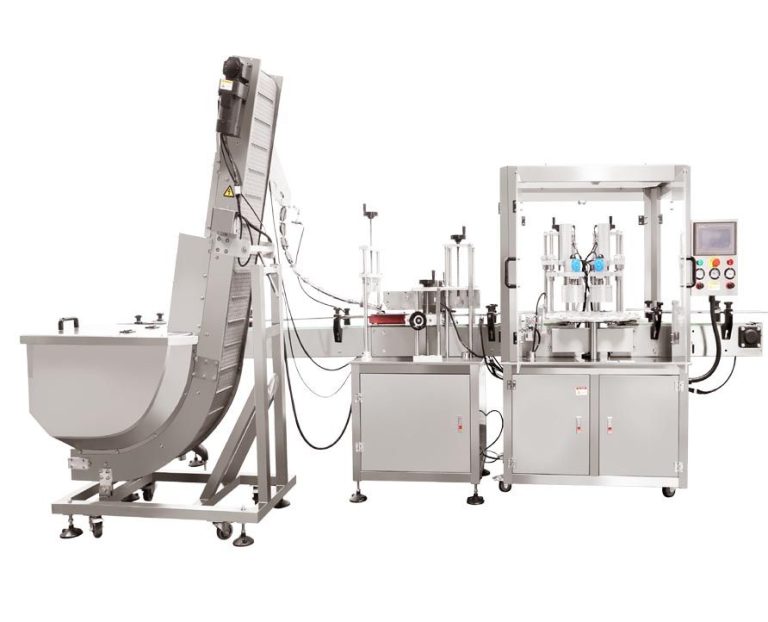

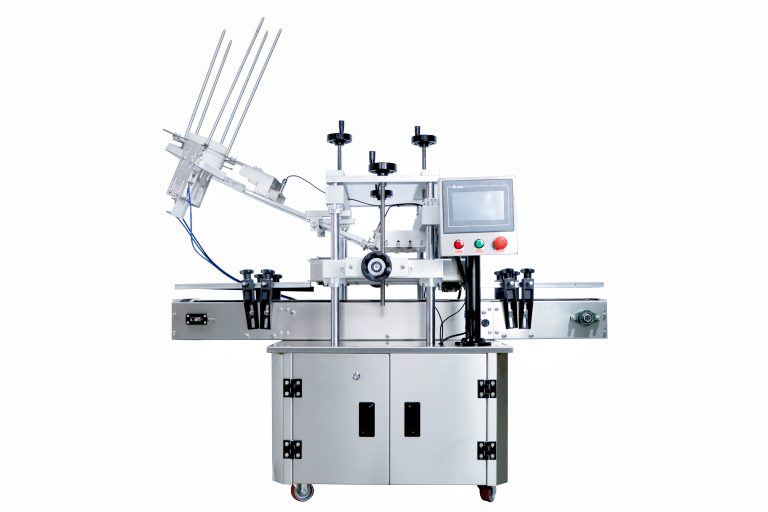

Coconut oil has become increasingly popular in recent years due to its numerous health benefits and versatile uses. As a result, the demand for coconut oil production has also risen, leading to the need for efficient and reliable machinery to streamline the process. One essential piece of equipment for coconut oil production is the automatic tin can seaming machine, which plays a crucial role in sealing the cans to ensure product freshness and longevity.

When it comes to choosing the right automatic tin can seaming machine for coconut oil production, there are several factors to consider. One of the most important considerations is the size and capacity of the machine. The size of the machine should be able to accommodate the volume of coconut oil production required by your business. It is essential to choose a machine that can handle the workload efficiently without compromising on the quality of the final product.

Another crucial factor to consider when selecting an automatic tin can seaming machine is the speed and efficiency of the machine. A high-speed machine can significantly increase productivity and reduce production time, ultimately leading to cost savings for your business. Additionally, an efficient machine can help minimize downtime and ensure a smooth production process.

In addition to size and speed, it is essential to consider the quality and durability of the automatic tin can seaming machine. Investing in a high-quality machine can help prevent breakdowns and maintenance issues, ultimately saving you time and money in the long run. Look for machines made from durable materials that can withstand the rigors of continuous use in a production environment.

Furthermore, it is crucial to consider the ease of use and maintenance of the automatic tin can seaming machine. A user-friendly machine can help streamline the production process and reduce the risk of errors or accidents. Additionally, a machine that is easy to maintain can help prolong its lifespan and ensure consistent performance over time.

When choosing an automatic tin can seaming machine for coconut oil production, it is also essential to consider the reputation and reliability of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machinery and providing excellent customer service. Reading reviews and testimonials from other customers can help you gauge the reliability and performance of the machine before making a purchase.

In conclusion, choosing the right automatic tin can seaming machine for coconut oil production is essential for ensuring a smooth and efficient production process. Consider factors such as size, speed, quality, ease of use, and manufacturer reputation when making your decision. By investing in a high-quality machine that meets your production needs, you can help streamline your operations and produce high-quality coconut oil for your customers.

-768x622.jpg)