Advantages of Using Automatic Servo Claw Screw Capper Equipment

Automatic servo claw screw capper equipment is a valuable tool for businesses looking to streamline their packaging processes. This innovative technology offers a range of advantages that can help improve efficiency, reduce costs, and enhance overall productivity. In this article, we will explore some of the key benefits of using automatic servo claw screw capper equipment in your packaging operations.

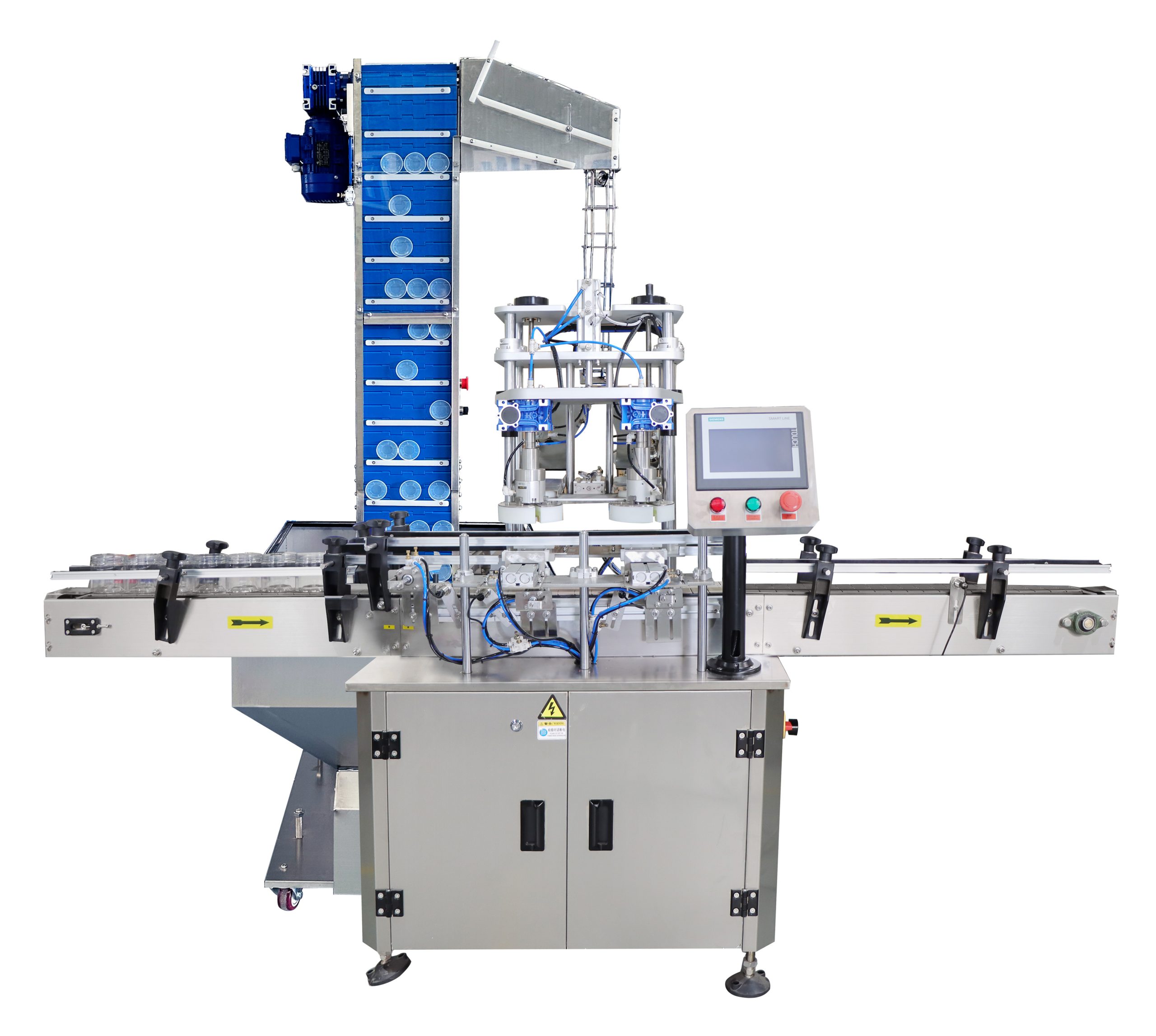

One of the primary advantages of automatic servo claw screw capper equipment is its ability to increase production speed. By automating the capping process, this equipment can cap bottles or containers at a much faster rate than manual capping methods. This can help businesses meet tight production deadlines and keep up with high demand without sacrificing quality.

In addition to speed, automatic servo claw screw capper equipment also offers improved accuracy. The servo-driven technology ensures precise and consistent capping, reducing the risk of errors and ensuring that each bottle is sealed correctly. This can help minimize product waste and rework, saving businesses time and money in the long run.

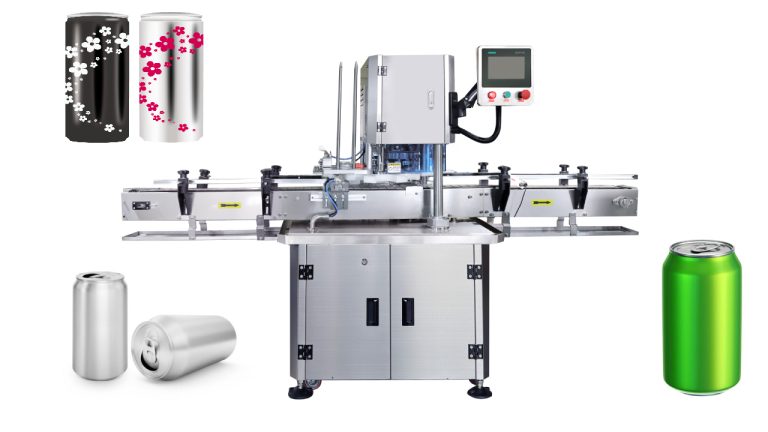

Another key advantage of automatic servo claw screw capper equipment is its versatility. This equipment is designed to handle a wide range of bottle sizes and shapes, making it suitable for a variety of packaging applications. Whether you are capping bottles of different heights, diameters, or materials, automatic servo claw screw capper equipment can be easily adjusted to accommodate your specific needs.

Furthermore, automatic servo claw screw capper equipment is user-friendly and easy to operate. With intuitive controls and programmable settings, operators can quickly set up the equipment and make adjustments as needed. This can help reduce training time and ensure that your packaging operations run smoothly and efficiently.

Additionally, automatic servo claw screw capper equipment is designed to be durable and reliable. Built with high-quality materials and advanced technology, this equipment is built to withstand the rigors of continuous use in a production environment. This can help minimize downtime and maintenance costs, allowing businesses to focus on their core operations without worrying about equipment failures.

Overall, the advantages of using automatic servo claw screw capper equipment are clear. From increased production speed and accuracy to versatility and ease of use, this technology offers a range of benefits that can help businesses improve their packaging processes and stay competitive in today’s fast-paced market. If you are looking to enhance your packaging operations, consider investing in automatic servo claw screw capper equipment to take your business to the next level.