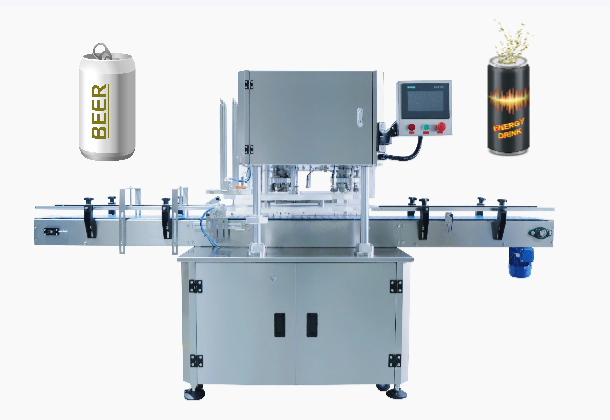

Semi-automatic can sealers have the potential to bring about a revolutionary change in your packaging process. Let’s explore how!

Firstly, they offer enhanced efficiency. With semi-automatic functionality, the sealing operation becomes quicker and more streamlined, reducing the time spent on packaging.

The precision and consistency of the seals provided by these sealers ensure the quality and integrity of your products. This means less risk of leaks or spoilage, which can save you significant costs in the long run.

They are highly adaptable. Whether you have different can sizes or materials, semi-automatic can sealers can handle the variety, giving you the flexibility to meet diverse packaging needs.

The ease of operation means that your staff can quickly get up to speed, minimizing training time and maximizing productivity.

These sealers also contribute to a more organized and efficient workflow on your packaging line. They can integrate smoothly with other packaging equipment, improving the overall process.

Moreover, semi-automatic can sealers often come with user-friendly maintenance features, reducing downtime and ensuring continuous operation.

In conclusion, incorporating semi-automatic can sealers into your packaging process can lead to improved quality, increased efficiency, and greater flexibility, ultimately giving your business a competitive edge.