Table of Contents

Increased Efficiency and Productivity in Food Packaging with Automatic Seamer Machines

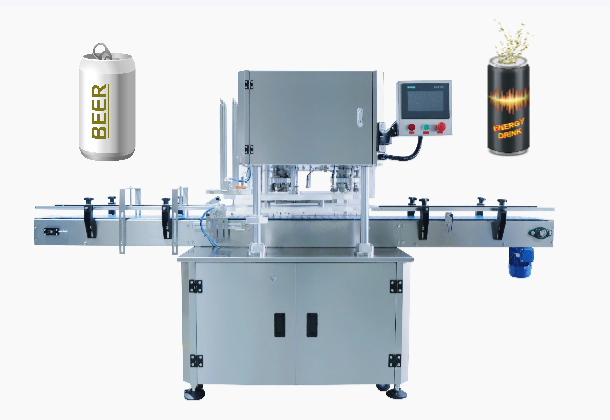

In the fast-paced world of the food industry, efficiency and productivity are key factors in ensuring that products are packaged and delivered in a timely manner. One technology that has revolutionized the packaging process is the automatic seamer machine. These machines have become an essential tool in the food industry, allowing for faster and more precise sealing of cans and containers.

Automatic seamer machines are designed to streamline the process of sealing cans and containers by automatically feeding, sealing, and discharging them. This automation eliminates the need for manual labor, reducing the risk of human error and increasing overall efficiency. With the ability to seal hundreds of cans per minute, automatic seamer machines have significantly increased productivity in food packaging facilities.

One of the key benefits of using automatic seamer machines is the consistency and precision they provide in sealing cans and containers. Manual sealing can often result in inconsistencies in the seal, leading to potential leaks or contamination. Automatic seamer machines ensure that each can is sealed with the same level of precision, reducing the risk of product spoilage and ensuring that products are delivered to consumers in optimal condition.

Furthermore, automatic seamer machines are equipped with advanced technology that allows for quick changeovers between different can sizes and types. This flexibility is crucial in the food industry, where products are often packaged in a variety of containers. With automatic seamer machines, manufacturers can easily switch between different packaging formats without the need for extensive downtime, allowing for greater versatility in production.

Another advantage of automatic seamer machines is their ability to improve overall safety in the packaging process. Manual sealing can be a hazardous task, with the risk of injuries from sharp edges or hot sealing equipment. Automatic seamer machines eliminate the need for manual intervention, reducing the risk of accidents and creating a safer working environment for employees.

In addition to increasing efficiency and productivity, automatic seamer machines also offer cost savings for food manufacturers. By automating the sealing process, manufacturers can reduce labor costs and improve overall production output. The precision and consistency provided by automatic seamer machines also help to minimize product waste, ensuring that every can is sealed correctly and reducing the risk of costly recalls.

Overall, the application of automatic seamer machines in the food industry has revolutionized the packaging process, providing manufacturers with a reliable and efficient solution for sealing cans and containers. With their ability to increase productivity, improve safety, and reduce costs, automatic seamer machines have become an essential tool for food packaging facilities looking to stay competitive in a fast-paced market.

As technology continues to advance, we can expect to see further innovations in automatic seamer machines, with even greater efficiency and capabilities. For now, however, it is clear that these machines have already made a significant impact on the food industry, helping manufacturers to meet the demands of consumers and deliver high-quality products in a timely manner.

Ensuring Food Safety and Quality through Automatic Seamer Machine Technology

In the food industry, ensuring food safety and quality is of utmost importance. One way that this can be achieved is through the use of automatic seamer machines. These machines play a crucial role in the packaging process, ensuring that food products are sealed properly and securely. This not only helps to maintain the freshness of the food but also prevents contamination and spoilage.

Automatic seamer machines are designed to seal cans or containers with precision and efficiency. They are equipped with advanced technology that allows them to seal a large number of containers in a short amount of time. This is particularly beneficial for food manufacturers who need to package their products quickly and efficiently to meet consumer demand.

One of the key advantages of using automatic seamer machines is that they help to maintain the integrity of the food product. By sealing the containers properly, these machines prevent air and moisture from entering, which can lead to spoilage. This is especially important for perishable food items that need to be stored for an extended period of time.

Furthermore, automatic seamer machines help to ensure that the packaging is tamper-proof. This is essential for maintaining the safety of the food product and preventing any potential contamination. By creating a secure seal, these machines give consumers peace of mind knowing that the product they are purchasing has not been tampered with.

Another benefit of using automatic seamer machines is that they help to improve the overall efficiency of the packaging process. These machines are capable of sealing containers at a much faster rate than manual methods, saving time and labor costs for food manufacturers. This allows them to increase their production output and meet the demands of the market more effectively.

Additionally, automatic seamer machines are equipped with sensors and monitoring systems that ensure the quality of the seal. This helps to prevent any defects or inconsistencies in the packaging, which could compromise the safety and quality of the food product. By detecting any issues early on, these machines help to maintain the high standards of the food industry.

In conclusion, the application of automatic seamer machines in the food industry plays a crucial role in ensuring food safety and quality. These machines help to seal containers with precision and efficiency, maintaining the freshness of the food product and preventing contamination. They also improve the overall efficiency of the packaging process, saving time and labor costs for food manufacturers. With their advanced technology and monitoring systems, automatic seamer machines help to maintain the high standards of the food industry and provide consumers with safe and high-quality products.

Cost Savings and Sustainability Benefits of Using Automatic Seamer Machines in the Food Industry

Automatic seamer machines have become an essential tool in the food industry, revolutionizing the way food products are sealed and packaged. These machines offer a wide range of benefits, including cost savings and sustainability advantages, making them a popular choice for food manufacturers looking to improve efficiency and reduce waste.

One of the primary benefits of using automatic seamer machines in the food industry is the cost savings they provide. These machines are designed to seal cans quickly and efficiently, reducing the amount of labor required for the packaging process. This can result in significant savings for food manufacturers, as they can produce more products in less time, with fewer employees needed to operate the machines.

In addition to labor savings, automatic seamer machines also help reduce material waste. These machines are designed to seal cans with precision, ensuring that each can is properly sealed and protected from contamination. This reduces the likelihood of product spoilage and waste, ultimately saving food manufacturers money on lost inventory.

Furthermore, automatic seamer machines are designed to be energy-efficient, further reducing operating costs for food manufacturers. These machines are equipped with advanced technology that allows them to operate at optimal efficiency, using less energy than traditional sealing methods. This not only saves money on energy costs but also reduces the environmental impact of food production.

Another significant benefit of using automatic seamer machines in the food industry is the sustainability advantages they offer. These machines are designed to be durable and long-lasting, reducing the need for frequent replacements and repairs. This helps reduce the amount of waste generated by food manufacturers, as they can use the same machines for an extended period of time without needing to dispose of them.

Additionally, automatic seamer machines help reduce the environmental impact of food production by minimizing the use of packaging materials. These machines are designed to seal cans with precision, ensuring that each can is properly sealed and protected without the need for excess packaging. This helps reduce the amount of waste generated by food manufacturers and minimizes the environmental footprint of the industry.

Overall, the application of automatic seamer machines in the food industry offers a wide range of cost savings and sustainability benefits. These machines help food manufacturers improve efficiency, reduce waste, and minimize their environmental impact, making them an essential tool for modern food production. By investing in automatic seamer machines, food manufacturers can improve their bottom line while also contributing to a more sustainable future for the industry.

-768x622.jpg)