Table of Contents

Jar Filling Machines: A Comprehensive Guide

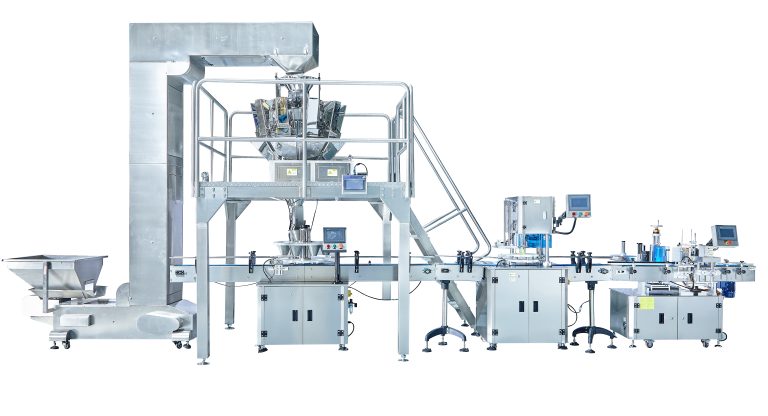

Filling machines are essential equipment in the packaging industry, especially when it comes to filling jars, tubes, and viscous liquids. These machines are designed to efficiently and accurately fill containers with various types of products, ranging from food and beverages to cosmetics and pharmaceuticals. In this article, we will explore the different types of filling machines available for filling jars, tubes, and viscous liquids, and how they can benefit your packaging operations.

One of the most common types of filling machines for jars is the piston filling machine. This machine uses a piston to dispense a precise amount of product into each jar, ensuring consistent fill levels and minimizing product waste. Piston filling machines are ideal for filling thick or viscous liquids, such as sauces, creams, and gels. They can be easily adjusted to accommodate different jar sizes and fill volumes, making them versatile and cost-effective for a wide range of applications.

Another popular option for filling jars is the overflow filling machine. This type of machine is commonly used for filling liquids that foam or bubble, such as shampoos, lotions, and cleaning products. The overflow filling machine works by filling each jar to a predetermined level and then allowing any excess product to overflow into a reservoir, ensuring a consistent fill level and preventing spills or leaks. This type of machine is highly efficient and can handle high-speed filling operations with ease.

For filling tubes, the tube filling machine is the go-to choice for many packaging operations. These machines are specifically designed to fill and seal tubes of various sizes and materials, such as plastic, aluminum, and laminate. Tube filling machines can handle a wide range of products, including creams, ointments, toothpaste, and adhesives. They are equipped with precision dosing systems to ensure accurate fill volumes and can be customized with additional features, such as hot air sealing or ultrasonic sealing, to meet specific packaging requirements.

When it comes to filling viscous liquids, such as honey, syrups, and pastes, the gear pump filling machine is an excellent option. This type of machine uses a gear pump to dispense thick or sticky products with precision and consistency. Gear pump filling machines are highly versatile and can handle a wide range of viscosities, making them ideal for filling a variety of products in jars, bottles, and containers. These machines are easy to clean and maintain, making them a reliable and cost-effective solution for packaging operations that require filling viscous liquids.

In conclusion, choosing the right filling machine for jars, tubes, and viscous liquids is essential for ensuring efficient and accurate packaging operations. Whether you need to fill jars with sauces, tubes with creams, or viscous liquids with precision, there is a filling machine available to meet your specific needs. By investing in the right type of filling machine for your products, you can streamline your packaging process, improve product quality, and increase overall productivity. Consider the different types of filling machines mentioned in this article and choose the one that best suits your packaging requirements.

Exploring the Different Types of Tube Filling Machines

Filling machines are essential equipment in various industries, including food and beverage, pharmaceuticals, cosmetics, and more. These machines are designed to efficiently fill containers such as jars, tubes, and bottles with various types of products, including liquids, creams, gels, and powders. In this article, we will explore the different types of filling machines specifically designed for jars, tubes, and viscous liquids.

One of the most common types of filling machines for jars is the piston filling machine. This machine uses a piston to accurately dispense a predetermined amount of product into each jar. The piston is driven by a pneumatic or electric system, ensuring precise filling and minimizing product waste. Piston filling machines are ideal for filling thick or viscous products such as sauces, creams, and pastes.

Another popular option for filling jars is the overflow filling machine. This machine is commonly used for filling liquids that foam or bubble, such as shampoos, lotions, and cleaning solutions. The overflow filling machine works by filling each jar to a predetermined level, ensuring a consistent fill level across all jars. This type of filling machine is also suitable for filling jars with narrow openings, as it minimizes spillage and product waste.

When it comes to filling tubes, the most common type of filling machine is the tube filling and sealing machine. This machine is specifically designed to fill and seal tubes with various types of products, including creams, gels, ointments, and toothpaste. The tube filling and sealing machine works by first filling the tube with the desired product and then sealing it to prevent leakage. This type of filling machine is highly efficient and can fill a large number of tubes in a short amount of time.

For filling viscous liquids such as honey, syrups, and oils, the gear pump filling machine is often the best choice. This machine uses a gear pump to accurately dispense thick liquids into containers with minimal air entrapment. The gear pump filling machine is highly versatile and can handle a wide range of viscosities, making it ideal for filling a variety of products. Additionally, this type of filling machine is easy to clean and maintain, ensuring consistent and reliable performance.

In conclusion, there are several types of filling machines available for jars, tubes, and viscous liquids, each designed to meet specific needs and requirements. Whether you are filling jars with sauces, tubes with creams, or bottles with oils, there is a filling machine that can help streamline your production process and improve efficiency. By choosing the right type of filling machine for your product and container, you can ensure accurate fills, minimize product waste, and increase productivity. Consider the specific requirements of your product and production line when selecting a filling machine, and invest in a high-quality machine that will deliver consistent and reliable performance for years to come.

Viscous Liquid Filling Machines: Features and Benefits

Filling machines are essential equipment in various industries, including food and beverage, pharmaceuticals, and cosmetics. They are used to accurately fill containers such as jars, tubes, and bottles with different types of products, including viscous liquids. Viscous liquid filling machines are specifically designed to handle thick, sticky substances that are difficult to pour or dispense manually.

One of the key features of viscous liquid filling machines is their ability to handle a wide range of viscosities. These machines are equipped with special nozzles and pumps that can handle thick liquids such as creams, gels, pastes, and syrups. This versatility makes them ideal for filling a variety of products in different industries.

Another important feature of viscous liquid filling machines is their precision and accuracy. These machines are designed to fill containers with the exact amount of product, ensuring consistency and quality in every batch. This is especially important in industries where precise measurements are crucial, such as pharmaceuticals and cosmetics.

Viscous liquid filling machines are also designed for easy cleaning and maintenance. They are made of high-quality materials that are resistant to corrosion and wear, ensuring long-term durability and reliability. These machines are also easy to disassemble and clean, making them ideal for use in industries where hygiene is a top priority.

In addition to their features, viscous liquid filling machines offer several benefits to manufacturers. One of the main advantages of using these machines is increased efficiency and productivity. By automating the filling process, manufacturers can fill containers faster and more accurately, reducing waste and improving overall production efficiency.

Another benefit of viscous liquid filling machines is cost savings. These machines are designed to minimize product waste and spillage, saving manufacturers money in the long run. By filling containers with the exact amount of product, manufacturers can also reduce product giveaway and improve their bottom line.

Viscous liquid filling machines also help improve product quality and consistency. By filling containers with the exact amount of product every time, manufacturers can ensure that their products meet quality standards and customer expectations. This is especially important in industries where consistency is key, such as food and beverage.

Overall, viscous liquid filling machines are essential equipment for manufacturers who need to fill containers with thick, sticky substances. These machines offer a wide range of features and benefits, including versatility, precision, efficiency, and cost savings. By investing in a high-quality viscous liquid filling machine, manufacturers can improve their production processes and deliver high-quality products to their customers.