The Process of Sealing Canned Food

Canned food has been a staple in households for decades, providing a convenient and long-lasting option for preserving food. But have you ever wondered how canned food is sealed to ensure its freshness and safety? The process of sealing canned food is a crucial step in the production process, as it plays a key role in preventing contamination and spoilage.

The first step in sealing canned food is the filling of the cans with the desired food product. This is typically done using automated machinery that accurately measures and dispenses the correct amount of food into each can. Once the cans are filled, they are then moved to the sealing station where the sealing process begins.

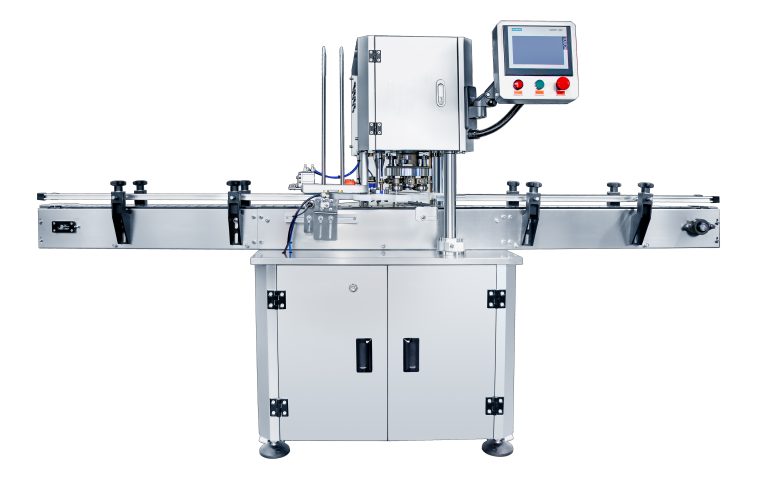

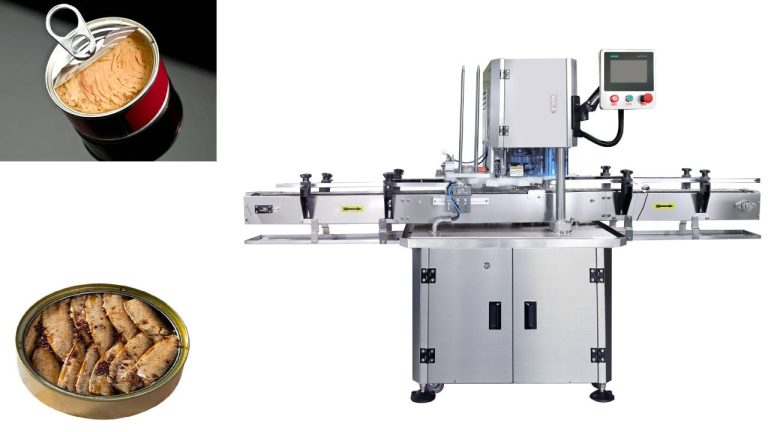

One common method of sealing canned food is through the use of a can seamer. A can seamer is a machine that uses a combination of pressure and heat to seal the lid onto the can. The lid is placed on top of the filled can, and the can seamer then applies pressure to the lid, crimping it onto the can to create a tight seal. The can seamer also uses heat to ensure that the seal is airtight, preventing any air or contaminants from entering the can.

Another method of sealing canned food is through the use of a double seaming process. In this process, the lid is first placed on top of the can, and a seaming machine is used to crimp the lid onto the can. The can is then moved to a second seaming machine, which applies a second crimp to further secure the lid onto the can. This double seaming process provides an extra layer of protection against contamination and spoilage.

In addition to the sealing process, canned food manufacturers also take steps to ensure the quality and safety of their products. Before the cans are sealed, they are typically subjected to a rigorous inspection process to check for any defects or contamination. This may include visual inspections, as well as tests for things like can integrity and seal strength.

Once the cans are sealed and inspected, they are then typically sent through a process known as retorting. Retorting is a heat sterilization process that helps to kill any bacteria or microorganisms that may be present in the food. The sealed cans are placed in a retort machine, which heats them to a specific temperature for a set amount of time to ensure that the food is safe for consumption.

Overall, the process of sealing canned food is a critical step in ensuring the safety and quality of the final product. By using methods like can seamers and double seaming, as well as conducting thorough inspections and retorting, canned food manufacturers are able to provide consumers with a reliable and long-lasting food option. So the next time you reach for a can of your favorite food, you can feel confident knowing that it has been sealed using a process designed to keep it fresh and safe for you to enjoy.