Table of Contents

Benefits of Using a Dust Cover Capping Machine for Milk Powder Can

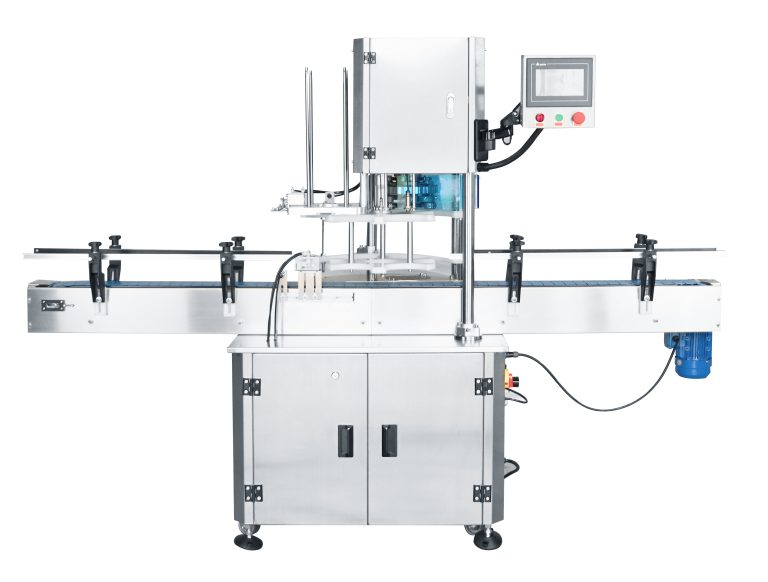

In the food and beverage industry, packaging plays a crucial role in ensuring the safety and quality of products. When it comes to packaging milk powder, one important aspect to consider is the dust cover capping process. A dust cover capping machine is a specialized piece of equipment designed to seal milk powder cans with a protective cover, preventing contamination and ensuring product freshness.

One of the key benefits of using a dust cover capping machine for milk powder cans is the improved hygiene and cleanliness it provides. By sealing the cans with a dust cover, the machine helps to prevent dust, dirt, and other contaminants from entering the packaging. This is especially important in the dairy industry, where maintaining high levels of hygiene is essential to prevent the growth of harmful bacteria and ensure product safety.

In addition to enhancing hygiene, a dust cover capping machine also helps to extend the shelf life of milk powder. By creating a tight seal on the cans, the machine helps to protect the product from exposure to air and moisture, which can lead to spoilage and degradation of quality. This not only helps to reduce food waste but also ensures that consumers receive a fresh and high-quality product every time.

Furthermore, using a dust cover capping machine can also improve the overall efficiency of the packaging process. These machines are designed to work quickly and accurately, sealing multiple cans in a matter of seconds. This can help to streamline production and reduce the need for manual labor, saving time and labor costs for manufacturers. Additionally, the consistent and precise sealing provided by the machine helps to minimize the risk of human error, ensuring that every can is properly sealed and protected.

Another benefit of using a dust cover capping machine for milk powder cans is the enhanced product presentation it provides. A sealed can with a dust cover not only looks more professional and appealing to consumers but also helps to maintain the integrity of the packaging during transportation and storage. This can be especially important for products that are displayed on shelves or in retail environments, where presentation plays a key role in attracting customers.

Overall, the use of a dust cover capping machine for milk powder cans offers a range of benefits for manufacturers, retailers, and consumers alike. From improved hygiene and product freshness to increased efficiency and enhanced presentation, these machines play a crucial role in ensuring the quality and safety of milk powder products. By investing in a dust cover capping machine, manufacturers can not only protect their products but also enhance their brand reputation and customer satisfaction.

How to Choose the Right Dust Cover Capping Machine for Milk Powder Can

When it comes to packaging milk powder cans, one of the most important machines to consider is the dust cover capping machine. This machine plays a crucial role in ensuring that the milk powder cans are properly sealed and protected from contaminants. With so many options available on the market, choosing the right dust cover capping machine can be a daunting task. In this article, we will discuss some key factors to consider when selecting a dust cover capping machine for milk powder cans.

First and foremost, it is important to consider the size and shape of the milk powder cans that will be used with the dust cover capping machine. Different machines are designed to accommodate different sizes and shapes of cans, so it is essential to choose a machine that is compatible with the specific cans you will be using. Additionally, consider the production capacity of the machine. If you have a high volume of milk powder cans to cap, you will need a machine that can keep up with the demand.

Another important factor to consider is the type of closure system that the dust cover capping machine uses. There are several different types of closure systems available, including screw caps, snap-on caps, and press-on caps. Each type of closure system has its own advantages and disadvantages, so it is important to choose a machine that uses a closure system that is suitable for your specific needs. Additionally, consider the level of automation that the machine offers. Some machines are fully automated, while others require manual intervention. Choose a machine that offers the level of automation that is appropriate for your production process.

In addition to considering the size, shape, closure system, and automation level of the dust cover capping machine, it is also important to consider the quality and reliability of the machine. Look for a machine that is made from high-quality materials and is built to last. Additionally, choose a machine from a reputable manufacturer with a track record of producing reliable and durable equipment. Investing in a high-quality dust cover capping machine will help ensure that your milk powder cans are properly sealed and protected.

When choosing a dust cover capping machine for milk powder cans, it is also important to consider the cost of the machine. Prices can vary significantly depending on the features and capabilities of the machine, so it is important to set a budget and stick to it. However, it is also important to remember that quality should not be sacrificed for cost. Investing in a high-quality machine may cost more upfront, but it will pay off in the long run by reducing maintenance and downtime costs.

In conclusion, choosing the right dust cover capping machine for milk powder cans is a crucial decision that can have a significant impact on the quality and efficiency of your production process. Consider factors such as size, shape, closure system, automation level, quality, reliability, and cost when selecting a machine. By taking the time to carefully evaluate your options and choose a machine that meets your specific needs, you can ensure that your milk powder cans are properly sealed and protected.