In the world of can packaging, the precision of semi-automatic can closing machines is a hidden gem waiting to be discovered. These machines offer a level of accuracy that is essential for ensuring the quality and integrity of canned products.

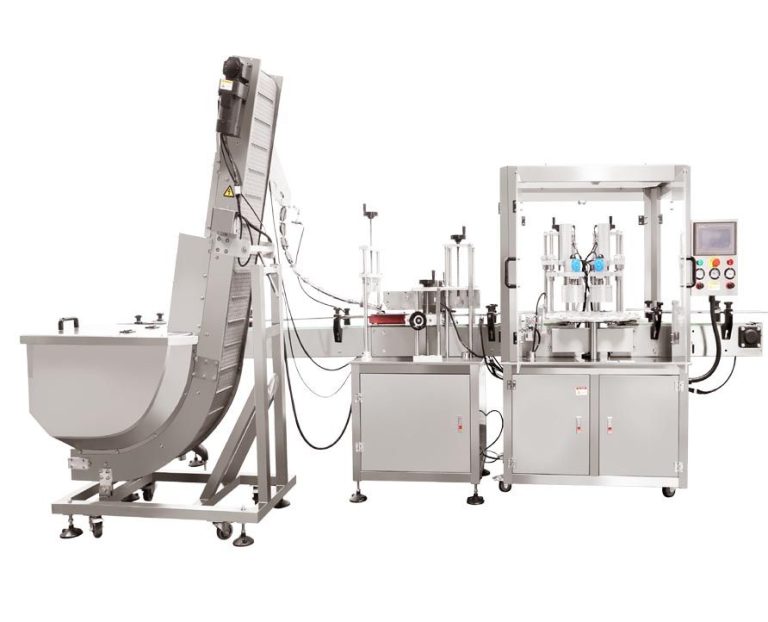

The semi-automatic can closing machines are engineered with meticulous attention to detail. Their components are finely calibrated to work in harmony, delivering a seamless and precise closing process. Every movement, from the application of pressure to the sealing of the can, is executed with exactitude.

One of the factors contributing to this precision is the advanced technology incorporated into the machines. Sensors and control systems monitor and adjust the closing parameters in real-time, guaranteeing that each can is sealed to the exact specifications. This eliminates variations and ensures consistency across all packaged cans.

The design of the closing mechanisms is another aspect that enhances precision. The jaws or sealing elements are precisely shaped and sized to fit the cans perfectly, providing a tight and uniform seal. This not only prevents leaks but also maintains the freshness and safety of the contents inside.

Operators also play a role in achieving precision. With user-friendly interfaces and clear instructions, they can easily control and fine-tune the machine’s settings to meet the specific requirements of different can sizes and products.

Discovering the precision of semi-automatic can closing machines means uncovering a valuable tool for businesses in the packaging industry. It leads to improved product quality, reduced waste, and increased customer satisfaction.

In conclusion, exploring the precision of these machines opens up a world of possibilities for efficient and reliable can packaging, setting new standards in the industry.