Benefits of Using a Glass Bottle Capping Machine

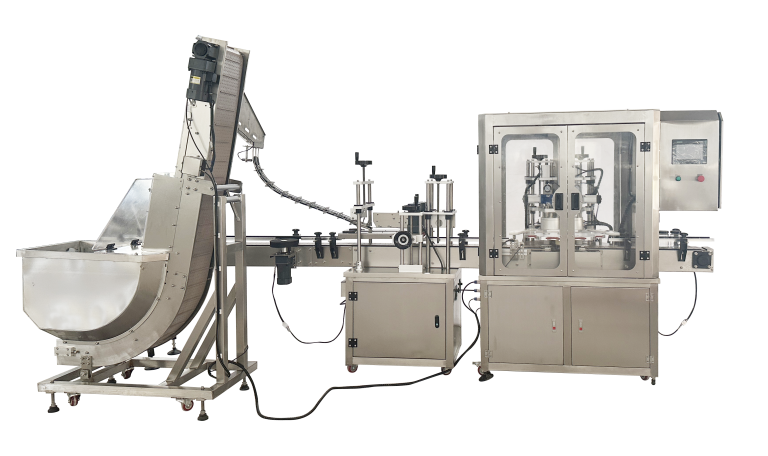

Glass bottle capping machines are essential tools for businesses in the beverage industry. These machines offer a wide range of benefits that can help streamline production processes and improve overall efficiency. In this article, we will explore some of the key advantages of using a glass bottle capping machine.

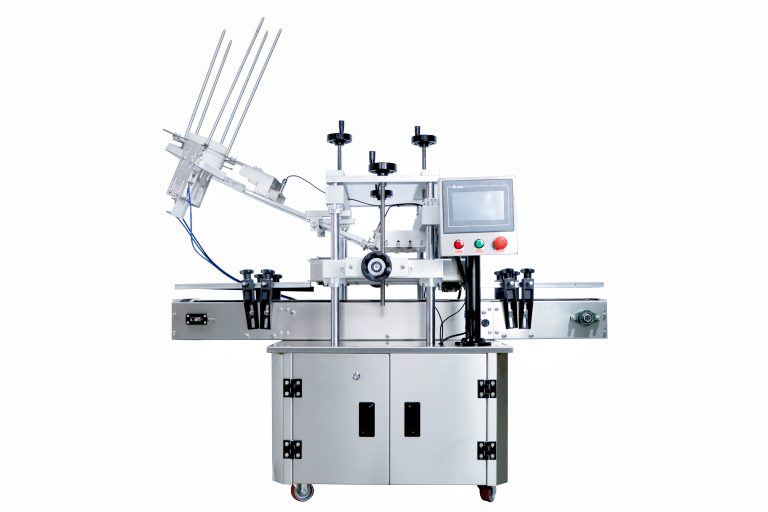

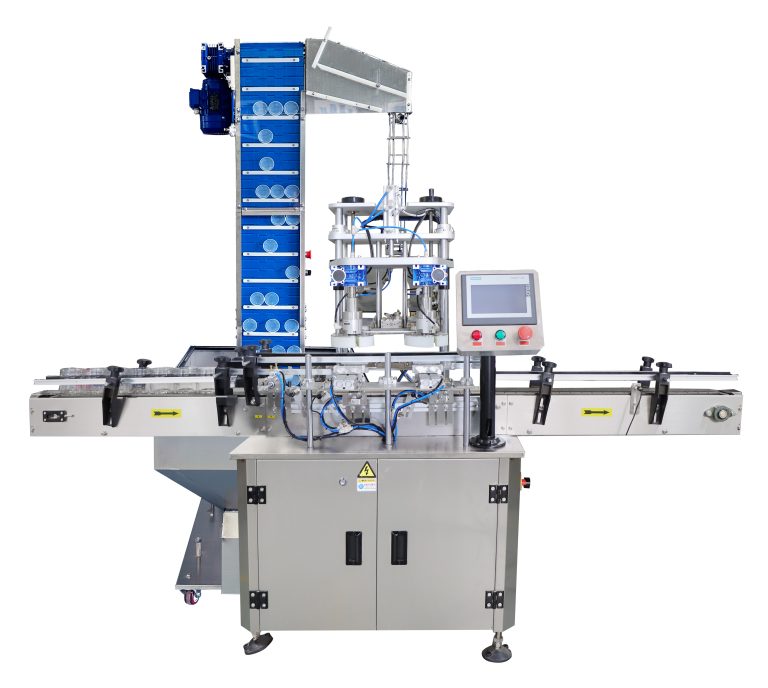

One of the primary benefits of using a glass bottle capping machine is the increased speed and consistency it provides. Manual capping can be a time-consuming and labor-intensive process, especially when dealing with large volumes of bottles. By automating this task with a capping machine, businesses can significantly reduce the time and effort required to cap each bottle. This not only speeds up production but also ensures that each bottle is capped with the same level of precision and consistency.

In addition to improving efficiency, glass bottle capping machines also help to reduce the risk of human error. Manual capping can lead to inconsistencies in the tightness of the caps, which can affect the quality and shelf life of the product. By using a capping machine, businesses can eliminate these inconsistencies and ensure that each bottle is properly sealed. This not only helps to maintain product quality but also reduces the risk of leaks or contamination during storage and transportation.

Another key benefit of using a glass bottle capping machine is the ability to customize the capping process to meet specific production requirements. These machines can be easily adjusted to accommodate different bottle sizes and cap types, allowing businesses to cap a wide range of products with ease. This flexibility is particularly useful for businesses that produce multiple products or frequently change their packaging designs.

Furthermore, glass bottle capping machines are designed to be durable and reliable, making them a cost-effective investment for businesses. These machines are built to withstand the rigors of continuous use and are less prone to breakdowns or malfunctions compared to manual capping methods. This reliability helps businesses minimize downtime and maintain consistent production schedules, ultimately leading to increased productivity and profitability.

In addition to these practical benefits, glass bottle capping machines also offer a more hygienic solution for capping bottles. Manual capping can expose bottles to contaminants from the environment or from the hands of workers, increasing the risk of spoilage or contamination. Capping machines help to minimize this risk by providing a sterile and controlled environment for capping, ensuring that each bottle is sealed in a clean and sanitary manner.

Overall, the benefits of using a glass bottle capping machine are clear. From increased speed and consistency to reduced risk of human error and improved customization options, these machines offer a range of advantages that can help businesses streamline their production processes and improve overall efficiency. By investing in a capping machine, businesses can not only save time and labor costs but also ensure the quality and integrity of their products.