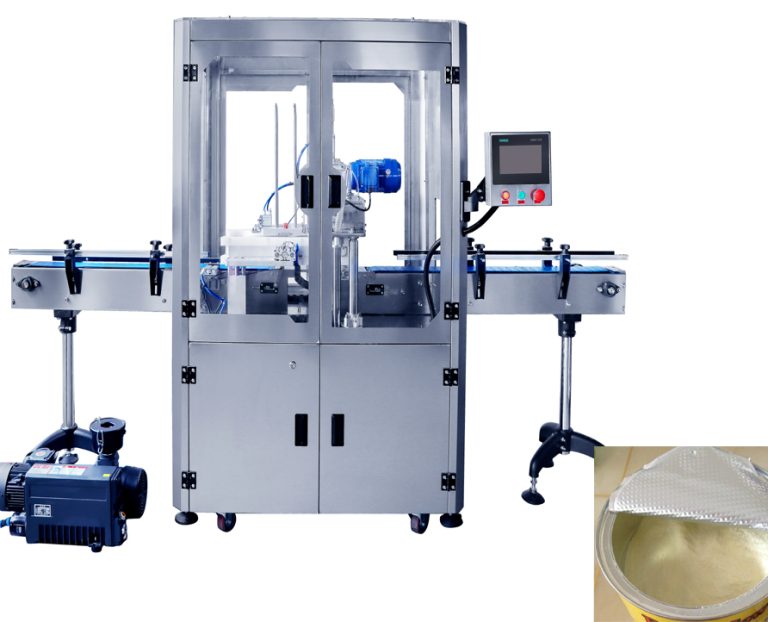

Semi-automatic vacuum capping machines play a crucial role in enhancing packaging efficiency in several ways.

Firstly, they significantly reduce the time taken for the capping process. With the ability to create a vacuum and seal containers rapidly, these machines can handle a large number of units in a shorter period compared to manual methods.

The consistent and precise operation of semi-automatic machines ensures that each cap is applied accurately and tightly. This eliminates the variations and potential errors that can occur with manual capping, reducing the need for rework and improving the overall output quality.

The vacuum feature not only enhances the preservation of the contents but also streamlines the packaging line. By removing air from the containers, it reduces the volume and creates a more compact package, allowing for easier handling and storage.

These machines are relatively easy to operate and do not require highly skilled labor. This means that training new operators is quick and straightforward, minimizing downtime and maximizing productivity.

Furthermore, semi-automatic vacuum capping machines can be integrated with other packaging equipment, creating a seamless and synchronized workflow. This integration eliminates bottlenecks and ensures a smooth transition from one packaging stage to another.

In summary, semi-automatic vacuum capping machines offer a combination of speed, accuracy, and simplicity that collectively contribute to a significant improvement in packaging efficiency, making them an invaluable asset in modern packaging operations.