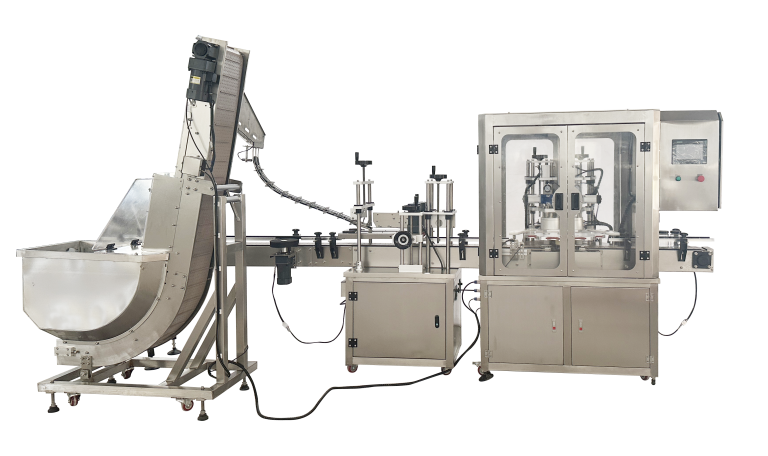

In the realm of milk powder packaging, an innovation has emerged that is redefining standards – the Automatic Vacuum Nitrogen Flushing Sealing Milk Powder Can Sealing Machine.

This remarkable machine represents a leap forward in sealing technology. Its automatic operation streamlines the packaging process, reducing human error and increasing efficiency to unprecedented levels.

The vacuum and nitrogen flushing feature is truly revolutionary. By creating a vacuum and introducing nitrogen, it provides an extra layer of protection for the milk powder. This not only preserves the quality and freshness of the powder but also enhances its nutritional value over time.

The precision with which it seals the cans is a testament to its innovation. Every seal is perfect, ensuring a tight and secure closure that prevents any leakage or contamination. This guarantees that the milk powder remains in optimal condition throughout its shelf life.

The adaptability of the machine is another aspect of its innovation. It can be easily integrated into different production lines and can handle various can sizes and shapes, offering flexibility to manufacturers.

Moreover, its innovative design takes into account sustainability. It uses materials and processes that minimize the environmental impact while still delivering top-notch sealing performance.

In conclusion, the Automatic Vacuum Nitrogen Flushing Sealing Milk Powder Can Sealing Machine is a shining example of innovative sealing. It combines advanced technology, efficiency, quality, and sustainability, setting a new benchmark in the packaging industry and ensuring that consumers receive the best possible milk powder products.