Table of Contents

Avantages de l’utilisation d’une machine de fermeture automatique de boîtes de conserve n° 401

Comment entretenir et nettoyer correctement une machine de fermeture automatique de boîtes de conserve n° 401

En conclusion, un entretien et un nettoyage appropriés de la machine de fermeture automatique de boîtes de conserve #401 sont essentiels pour garantir ses performances et sa longévité optimales. Des inspections, une lubrification et un nettoyage réguliers sont nécessaires pour éviter les pannes et garantir la sécurité des produits en conserve. En suivant les instructions du fabricant et en formant les employés au bon fonctionnement et à l’entretien, les entreprises peuvent maximiser l’efficacité et la durée de vie de cet équipement précieux.

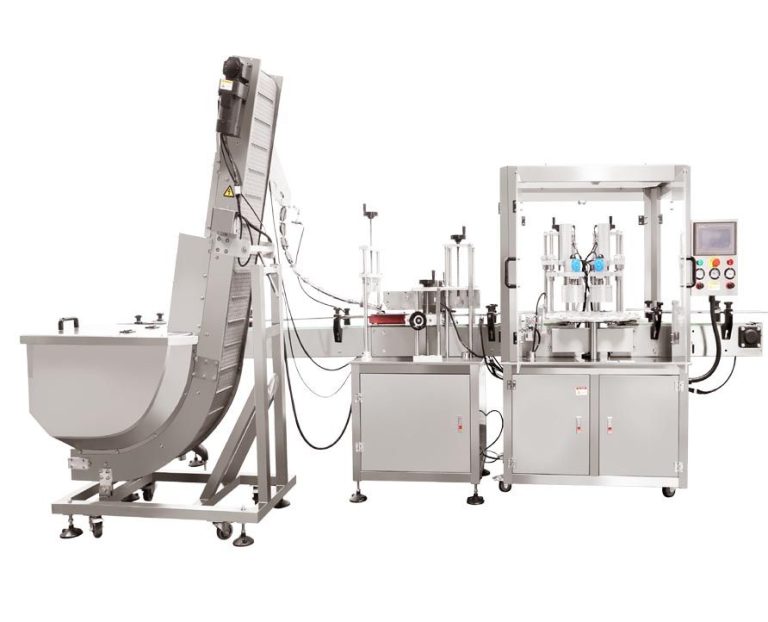

The #401 Automatic Tin Can Closing Machine is a valuable piece of equipment for any business involved in canning operations. This machine is designed to efficiently and effectively close tin cans, ensuring that the contents remain fresh and secure. However, like any piece of machinery, it requires regular maintenance and cleaning to ensure optimal performance and longevity.

Proper maintenance of the #401 Automatic Tin Can Closing Machine is essential to prevent breakdowns and ensure smooth operation. One of the first steps in maintaining this machine is to regularly inspect it for any signs of wear or damage. This includes checking the belts, gears, and other moving parts for any signs of wear or misalignment. Any damaged or worn parts should be replaced immediately to prevent further damage to the machine.

In addition to regular inspections, it is important to lubricate the moving parts of the #401 Automatic Tin Can Closing Machine. This helps to reduce friction and prevent premature wear. It is recommended to use a high-quality lubricant that is specifically designed for use with food processing equipment. Lubrication should be done according to the manufacturer’s instructions, and any excess lubricant should be wiped away to prevent contamination of the cans.

Cleaning the #401 Automatic Tin Can Closing Machine is also crucial to maintain its performance and ensure the safety of the canned products. Before cleaning, it is important to disconnect the machine from the power source to prevent any accidents. The machine should be cleaned regularly, especially after each use, to remove any food particles or debris that may have accumulated.

To clean the machine, start by removing any loose debris with a brush or vacuum. Then, use a mild detergent or cleaning solution to wipe down the surfaces of the machine. Pay special attention to areas that come into direct contact with the cans, such as the closing mechanism. Use a soft cloth or sponge to gently scrub away any stubborn stains or residue.

After cleaning, thoroughly rinse the machine with clean water to remove any traces of detergent or cleaning solution. It is important to ensure that no cleaning chemicals are left behind, as they can contaminate the canned products. Once the machine is rinsed, allow it to air dry completely before reconnecting it to the power source.

In addition to regular maintenance and cleaning, it is important to follow the manufacturer’s instructions for operating the #401 Automatic Tin Can Closing Machine. This includes using the machine within its specified capacity and avoiding any misuse or abuse that could cause damage. It is also important to train employees on the proper operation and maintenance of the machine to ensure its longevity and optimal performance.

In conclusion, proper maintenance and cleaning of the #401 Automatic Tin Can Closing Machine are essential to ensure its optimal performance and longevity. Regular inspections, lubrication, and cleaning are necessary to prevent breakdowns and ensure the safety of the canned products. By following the manufacturer’s instructions and training employees on proper operation and maintenance, businesses can maximize the efficiency and lifespan of this valuable piece of equipment.