Table of Contents

Benefits of Using an Automatic Melon Seeds Filling Sealing Machine Line

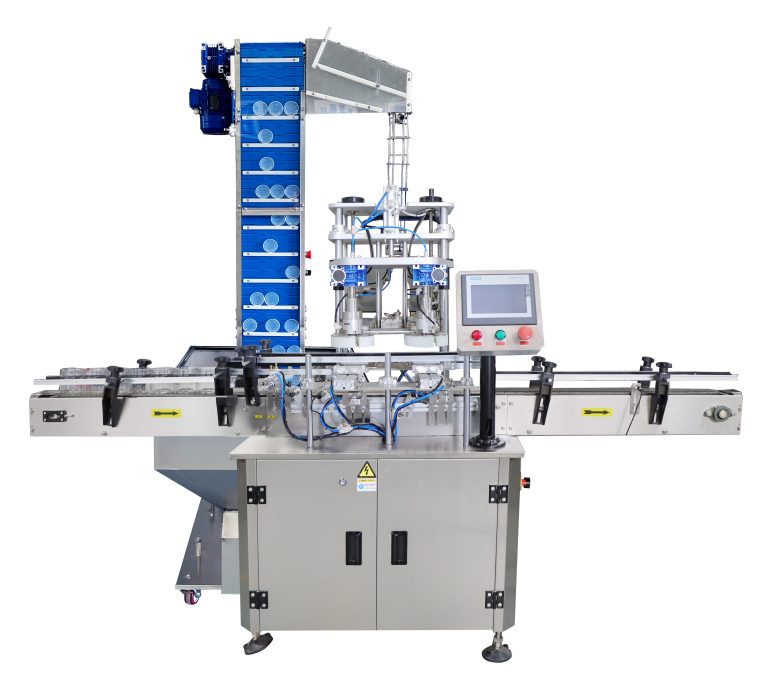

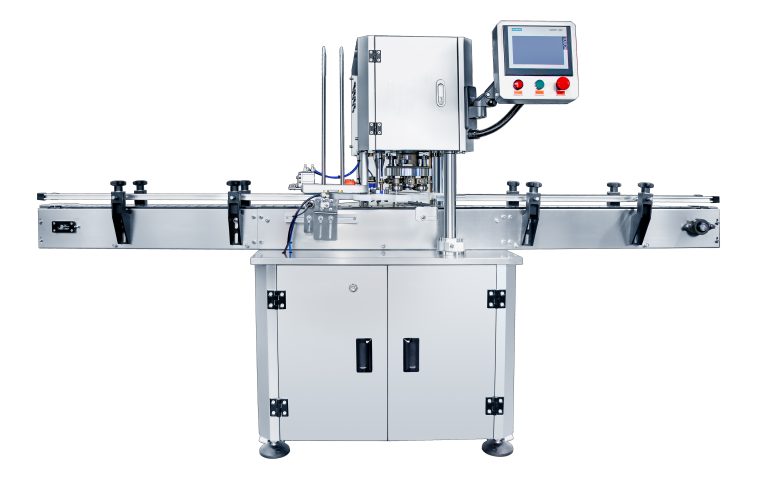

In the food packaging industry, efficiency and accuracy are key factors in ensuring the quality and safety of products. One of the ways to achieve this is by using an automatic melon seeds filling sealing machine line. This advanced technology offers numerous benefits that can greatly improve the production process and overall output of a food packaging facility.

One of the main advantages of using an automatic melon seeds filling sealing machine line is its ability to increase productivity. These machines are designed to fill and seal packages at a much faster rate than manual labor, allowing for higher output and faster turnaround times. This can be especially beneficial for companies that have high demand for their products and need to meet tight deadlines.

Additionally, automatic melon seeds filling sealing machine lines are highly accurate in their measurements and sealing processes. This helps to ensure that each package is filled with the correct amount of product and is properly sealed to maintain freshness and prevent contamination. This level of precision is difficult to achieve with manual labor and can greatly reduce the risk of errors and product waste.

Another benefit of using an automatic melon seeds filling sealing machine line is the consistency it provides in packaging. With manual labor, there is always a risk of human error, which can lead to inconsistencies in packaging quality. By using a machine line, companies can ensure that each package is filled and sealed in the same manner, resulting in a uniform and professional appearance for their products.

Furthermore, automatic melon seeds filling sealing machine lines are designed to be user-friendly and easy to operate. This makes it simple for employees to learn how to use the machines and reduces the need for extensive training. Additionally, these machines are equipped with safety features to protect workers from potential hazards, making them a safe and reliable option for food packaging facilities.

In addition to improving productivity and accuracy, automatic melon seeds filling sealing machine lines can also help to reduce labor costs. By automating the packaging process, companies can eliminate the need for manual labor and reallocate resources to other areas of the business. This can result in significant cost savings over time and improve the overall efficiency of the production process.

Overall, the benefits of using an automatic melon seeds filling sealing machine line are clear. From increased productivity and accuracy to consistency in packaging and cost savings, these machines offer a wide range of advantages for food packaging facilities. By investing in this advanced technology, companies can streamline their production process, improve the quality of their products, and ultimately enhance their competitiveness in the market.

How to Choose the Right Automatic Melon Seeds Filling Sealing Machine Line for Your Business

When it comes to packaging products like melon seeds, having the right equipment can make all the difference in efficiency and quality. Automatic melon seeds filling sealing machine lines are a popular choice for businesses looking to streamline their packaging process. These machines can fill and seal bags of melon seeds quickly and accurately, saving time and labor costs. However, with so many options available on the market, it can be overwhelming to choose the right machine for your business. In this article, we will discuss some key factors to consider when selecting an automatic melon seeds filling sealing machine line.

One of the first things to consider when choosing a machine line is the production capacity of your business. Different machines have different capacities, so it’s important to choose one that can keep up with your production needs. If you have a small business with low production volume, a smaller machine may be sufficient. However, if you have a larger operation with high production demands, you will need a machine with a higher capacity.

Another important factor to consider is the type of packaging you require for your melon seeds. Automatic melon seeds filling sealing machine lines come in various configurations, including vertical form fill seal machines, horizontal form fill seal machines, and pre-made pouch filling machines. Each type of machine is designed for different types of packaging, so it’s important to choose one that is compatible with the packaging materials you plan to use.

In addition to production capacity and packaging type, it’s also important to consider the level of automation you require. Some automatic melon seeds filling sealing machine lines are fully automated, while others require more manual intervention. Fully automated machines are more efficient and require less labor, but they also tend to be more expensive. If you have a smaller budget or prefer more control over the packaging process, a semi-automated machine may be a better option.

When choosing an automatic melon seeds filling sealing machine line, it’s also important to consider the quality and reliability of the machine. Look for machines from reputable manufacturers with a track record of producing high-quality equipment. It’s also a good idea to read reviews and testimonials from other customers to get an idea of the machine’s performance and reliability.

Finally, don’t forget to consider the cost of the machine line. Automatic melon seeds filling sealing machine lines can vary widely in price, so it’s important to choose a machine that fits within your budget. Keep in mind that the initial cost of the machine is just one factor to consider – you should also factor in ongoing maintenance and operating costs.

In conclusion, choosing the right automatic melon seeds filling sealing machine line for your business is a crucial decision that can impact your production efficiency and product quality. Consider factors such as production capacity, packaging type, level of automation, quality and reliability, and cost when making your decision. By taking the time to research and compare different machines, you can find the perfect machine line to meet your business needs.

Maintenance Tips for Ensuring Longevity of Your Automatic Melon Seeds Filling Sealing Machine Line

Automatic melon seeds filling sealing machine lines are essential equipment for businesses in the food packaging industry. These machines are designed to efficiently fill and seal bags of melon seeds, ensuring product freshness and quality. To ensure the longevity and optimal performance of your automatic melon seeds filling sealing machine line, it is crucial to follow proper maintenance practices. In this article, we will discuss some maintenance tips that will help you keep your machine line running smoothly for years to come.

Regular cleaning is key to maintaining the efficiency of your automatic melon seeds filling sealing machine line. Over time, dust, debris, and residue from the melon seeds can build up on the machine’s components, leading to decreased performance and potential breakdowns. To prevent this, it is important to clean the machine regularly. Use a soft brush or cloth to remove any debris from the machine’s surfaces, and use a mild detergent to clean the components thoroughly. Be sure to dry the machine completely before using it again to prevent rust and corrosion.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear and tear. Check the seals, belts, and other components for any damage or deterioration, and replace them as needed. It is also important to lubricate the moving parts of the machine regularly to prevent friction and ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer for best results.

Another important maintenance tip for your automatic melon seeds filling sealing machine line is to calibrate the machine regularly. Over time, the machine’s settings may drift, leading to inaccurate filling and sealing. To prevent this, it is important to calibrate the machine according to the manufacturer’s instructions. This will ensure that the machine is operating at optimal efficiency and producing high-quality sealed bags of melon seeds.

It is also important to train your staff on proper machine operation and maintenance. Make sure that your employees are familiar with the machine’s functions and know how to operate it safely. Provide training on proper cleaning and maintenance procedures, and encourage your staff to report any issues or concerns with the machine promptly. By investing in proper training for your employees, you can prevent costly breakdowns and ensure the longevity of your automatic melon seeds filling sealing machine line.

Finally, it is important to schedule regular maintenance checks with a qualified technician. A professional technician will be able to identify any potential issues with the machine and address them before they become major problems. Regular maintenance checks can help prevent costly repairs and downtime, ensuring that your automatic melon seeds filling sealing machine line continues to operate efficiently for years to come.

In conclusion, proper maintenance is essential for ensuring the longevity and optimal performance of your automatic melon seeds filling sealing machine line. By following the maintenance tips outlined in this article, you can keep your machine running smoothly and efficiently, producing high-quality sealed bags of melon seeds for your customers. Invest in regular cleaning, inspection, calibration, training, and maintenance checks to keep your machine line in top condition. With proper care and maintenance, your automatic melon seeds filling sealing machine line will continue to be a valuable asset to your business for years to come.