Table of Contents

Benefits of Using Glass Bottle Vacuum Capping Machine in Beverage Industry

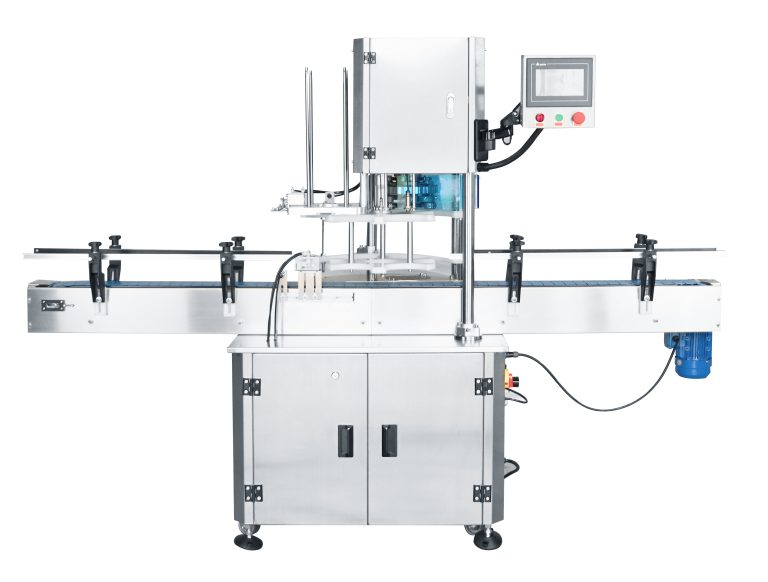

Glass bottle vacuum capping machines have become an essential tool in the beverage industry, providing numerous benefits to manufacturers looking to improve their production processes. These machines are designed to securely seal glass bottles with a vacuum cap, ensuring that the contents remain fresh and free from contamination. In this article, we will explore the various advantages of using a glass bottle vacuum capping machine in the beverage industry.

One of the primary benefits of using a glass bottle vacuum capping machine is the ability to maintain product quality and freshness. By creating a vacuum seal, these machines prevent oxygen from entering the bottle, which can cause oxidation and spoilage of the beverage. This ensures that the product retains its flavor and aroma, providing consumers with a high-quality drinking experience.

In addition to preserving product quality, glass bottle vacuum capping machines also help to extend the shelf life of beverages. By sealing the bottles tightly, these machines prevent bacteria and other contaminants from entering, reducing the risk of spoilage and ensuring that the product remains safe for consumption for a longer period of time. This can help manufacturers reduce waste and improve their overall efficiency.

Another advantage of using a glass bottle vacuum capping machine is the increased production speed and efficiency it offers. These machines are designed to cap bottles quickly and accurately, allowing manufacturers to streamline their production processes and meet high demand. This can help companies increase their output and improve their overall profitability.

Furthermore, glass bottle vacuum capping machines are versatile and can be used for a wide range of bottle sizes and shapes. This flexibility allows manufacturers to use the same machine for different products, reducing the need for multiple machines and saving on costs. Additionally, these machines are easy to operate and require minimal maintenance, making them a cost-effective solution for beverage manufacturers.

In conclusion, glass bottle vacuum capping machines offer numerous benefits to the beverage industry, including improved product quality, extended shelf life, increased production speed, and versatility. By investing in these machines, manufacturers can enhance their production processes, reduce waste, and ultimately improve their bottom line. As consumer demand for high-quality beverages continues to grow, glass bottle vacuum capping machines have become an essential tool for manufacturers looking to stay competitive in the market.

How to Choose the Right Glass Bottle Vacuum Capping Machine Manufacturer for Your Business

When it comes to choosing the right glass bottle vacuum capping machine manufacturer for your business, there are several factors to consider. The quality of the machines, the reputation of the manufacturer, and the level of customer service are all important aspects to take into account. In this article, we will discuss these factors in more detail to help you make an informed decision.

First and foremost, the quality of the glass bottle vacuum capping machines is crucial. You want to ensure that the machines you purchase are durable, reliable, and efficient. Look for a manufacturer that uses high-quality materials and advanced technology in their machines. This will not only ensure that the machines last longer but also that they perform at a high level consistently.

Another important factor to consider is the reputation of the manufacturer. Do some research to find out what other customers have to say about their experience with the manufacturer. Look for reviews and testimonials online, and ask for references if necessary. A manufacturer with a good reputation is more likely to provide you with quality machines and excellent customer service.

Speaking of customer service, this is another key factor to consider when choosing a glass bottle vacuum capping machine manufacturer. You want to work with a manufacturer that is responsive, helpful, and easy to communicate with. Look for a manufacturer that offers technical support, training, and maintenance services to ensure that your machines are always running smoothly.

In addition to these factors, you should also consider the cost of the machines and the manufacturer’s payment terms. Compare prices from different manufacturers to find the best deal for your budget. Keep in mind that the cheapest option may not always be the best option, so be sure to weigh the cost against the quality of the machines and the reputation of the manufacturer.

When choosing a glass bottle vacuum capping machine manufacturer, it is also important to consider the manufacturer’s experience and expertise in the industry. Look for a manufacturer that has been in business for a number of years and has a proven track record of success. An experienced manufacturer is more likely to understand your needs and provide you with the right machines for your business.

In conclusion, choosing the right glass bottle vacuum capping machine manufacturer for your business is a decision that should not be taken lightly. Consider the quality of the machines, the reputation of the manufacturer, the level of customer service, the cost, and the manufacturer’s experience and expertise. By taking these factors into account, you can make an informed decision that will benefit your business in the long run.