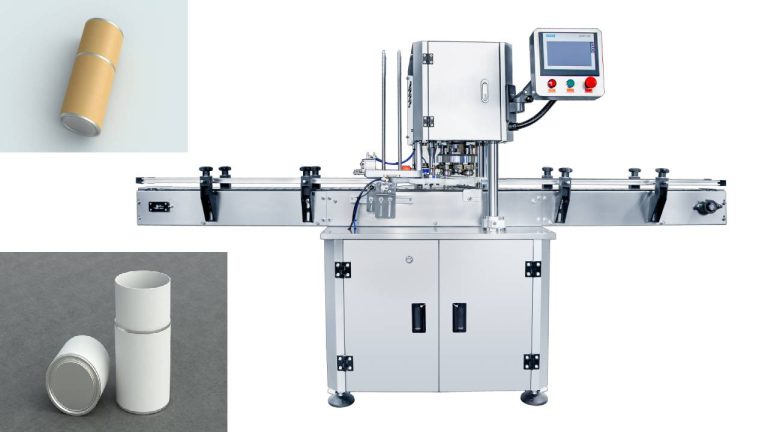

In the world of packaging, 4-wheel bottle capping machines have proven to be highly versatile, catering to a wide range of industries from beverages to chemicals.

In the beverage sector, these machines can handle various bottle shapes and sizes, whether it’s the classic glass bottles for carbonated drinks or plastic containers for juices and water. They can securely cap bottles at high speeds, ensuring product integrity and freshness.

When it comes to the chemical industry, 4-wheel capping machines are adapted to handle containers with different chemical compositions and viscosities. They can apply the appropriate torque to seal bottles containing aggressive or hazardous substances, providing a reliable closure to prevent leaks and spills.

The versatility of 4-wheel bottle capping machines lies in their ability to adjust to different cap types and materials. From screw-on caps to snap-on lids, these machines can be configured to meet the specific requirements of each product.

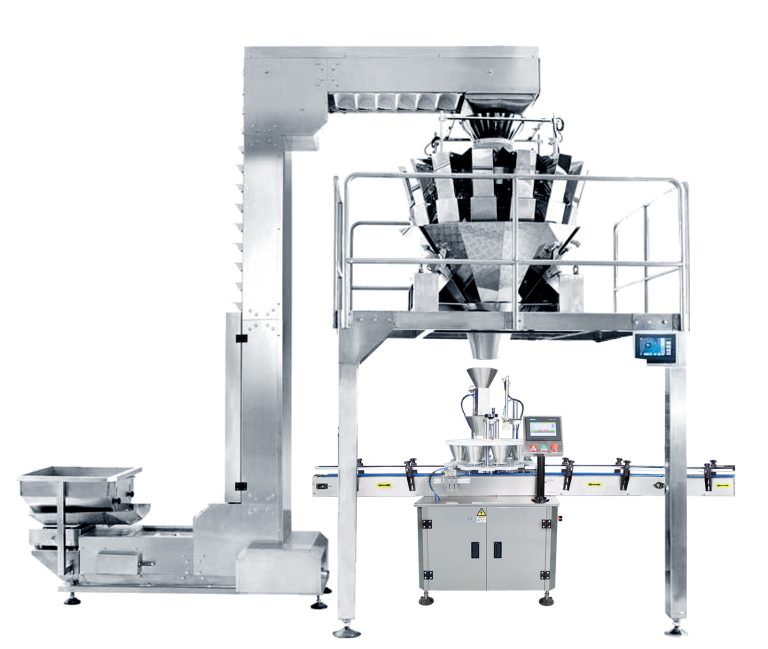

They also offer flexibility in terms of production volume. Whether it’s a small-scale production line or a large industrial operation, these machines can be scaled up or down to match the output needs.

The control systems of these machines are advanced, allowing for precise settings and adjustments based on the characteristics of the product and the packaging material. This ensures consistent and reliable capping across a diverse range of applications.

In conclusion, the 4-wheel bottle capping machines‘ ability to seamlessly transition between different industries and product types makes them an indispensable tool in modern packaging, demonstrating their true versatility and adaptability.

-768x622.jpg)