In the world of packaging, the ability to handle a wide range of can types is crucial. Dual head servo sealers have emerged as the ultimate solution, effortlessly sealing cans from soup to soda and everything in between.

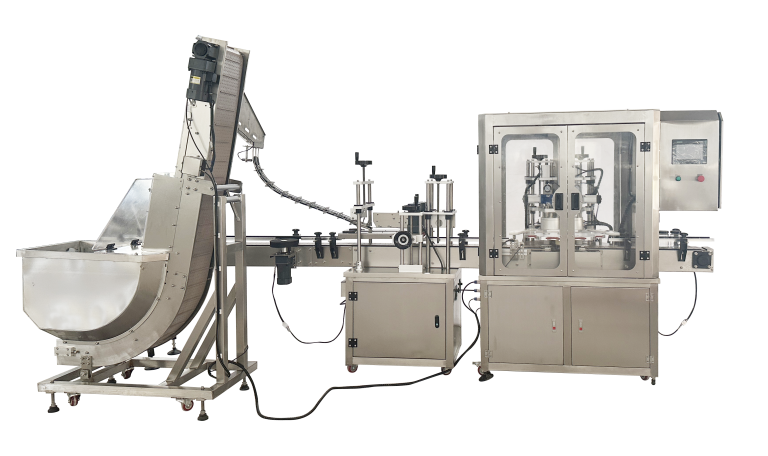

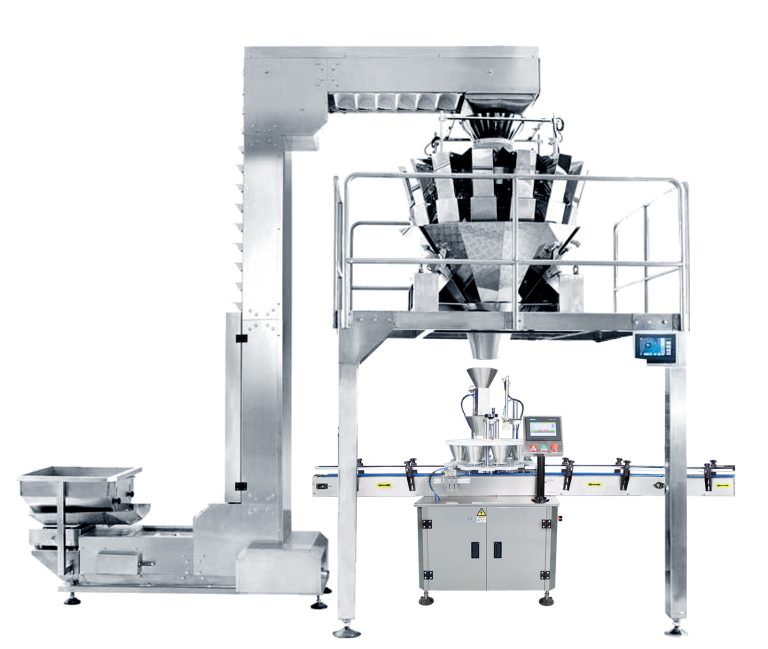

These advanced sealers are engineered with precision and flexibility in mind. Their sophisticated design allows them to adapt to the unique characteristics of each can type.

Whether it’s the thin walls of a soda can or the thicker material of a soup can, dual head servo sealers can adjust the sealing pressure and parameters accordingly. This ensures a perfect seal every time, regardless of the can’s size, shape, or material composition.

The servo technology enables precise control over the sealing process. It allows for fine-tuning to accommodate the specific requirements of different can contents, such as variations in pressure and temperature sensitivity.

Moreover, these sealers are capable of handling cans with different lid designs and materials. Whether it’s a traditional metal lid or a more modern composite material, they can provide a secure and reliable seal.

The speed and efficiency of dual head servo sealers also contribute to their ability to handle diverse can types. Their rapid operation means that production lines can keep moving smoothly, regardless of the variety of cans being processed.

In conclusion, dual head servo sealers are the unsung heroes of the packaging industry, seamlessly handling any can type with ease and precision. Their adaptability and performance make them an indispensable tool for businesses looking to meet the diverse demands of the market.