Table of Contents

Benefits of Using Granules Multi Heads Filling Canning Line

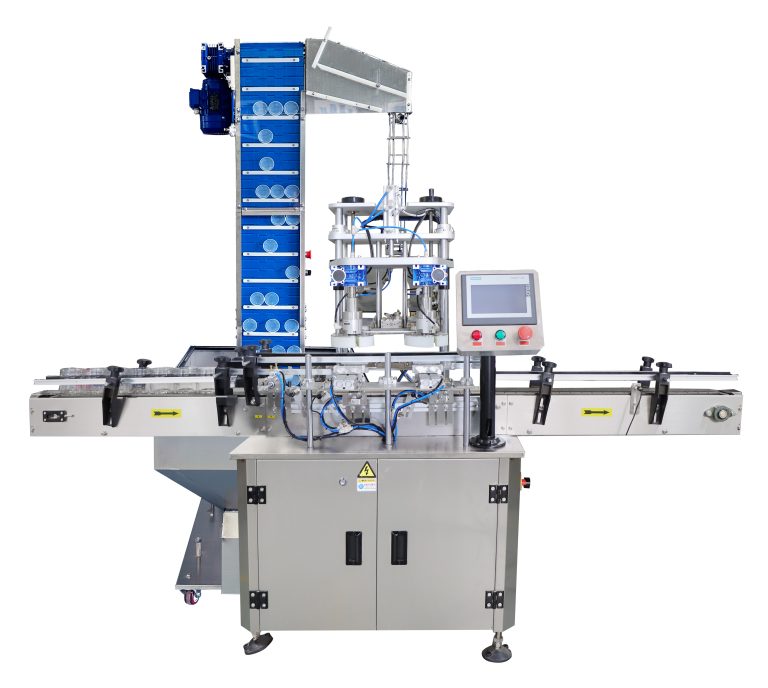

Granules multi heads filling canning line is a sophisticated piece of equipment that offers numerous benefits to businesses in the food and beverage industry. This innovative technology allows for efficient and precise filling of granular products into cans, jars, or other containers. By utilizing multiple heads, the filling process is expedited, resulting in higher productivity and reduced labor costs.

One of the key advantages of using a granules multi heads filling canning line is its ability to accurately measure and dispense the desired amount of product into each container. This ensures consistency in product quality and weight, which is essential for meeting regulatory requirements and customer expectations. The precision of the filling process also minimizes product waste, leading to cost savings for the business.

In addition to its accuracy, the granules multi heads filling canning line offers versatility in terms of the types of products it can handle. Whether it’s coffee beans, nuts, seeds, or other granular items, this equipment can accommodate a wide range of products with varying sizes and shapes. This flexibility allows businesses to streamline their production processes and easily switch between different products without the need for extensive reconfiguration.

Another benefit of using a granules multi heads filling canning line is its speed and efficiency. With multiple heads operating simultaneously, the filling process is significantly faster compared to manual filling or single-head machines. This increased throughput not only boosts productivity but also enables businesses to meet tight production deadlines and fulfill customer orders in a timely manner.

Furthermore, the automation provided by the granules multi heads filling canning line reduces the risk of human error and ensures consistent results across batches. This is particularly important for businesses that prioritize product quality and consistency. By eliminating manual intervention in the filling process, the equipment helps maintain the integrity of the product and minimizes the chances of contamination or spoilage.

The granules multi heads filling canning line also contributes to a safer working environment by reducing the physical strain on workers. Manual filling can be labor-intensive and repetitive, leading to fatigue and potential injuries. By automating the filling process, businesses can protect their employees from ergonomic hazards and create a more ergonomic and efficient production environment.

In conclusion, the benefits of using a granules multi heads filling canning line are numerous and significant for businesses in the food and beverage industry. From improved accuracy and efficiency to versatility and safety, this equipment offers a range of advantages that can enhance productivity, quality, and profitability. By investing in this innovative technology, businesses can streamline their production processes, reduce costs, and stay competitive in today’s fast-paced market.

How to Optimize Production Efficiency with Granules Multi Heads Filling Canning Line

In today’s fast-paced manufacturing industry, optimizing production efficiency is crucial for staying competitive and meeting customer demands. One way to achieve this is by investing in advanced equipment such as a granules multi heads filling canning line. This state-of-the-art machinery is designed to streamline the filling and canning process for granular products, making it faster, more accurate, and more cost-effective.

One of the key benefits of a granules multi heads filling canning line is its ability to fill multiple containers simultaneously. This means that you can fill more cans in less time, increasing your overall production output. Additionally, the precision of the filling process ensures that each can is filled to the exact same weight, reducing waste and ensuring consistency in your final product.

Another advantage of a granules multi heads filling canning line is its versatility. These machines are designed to handle a wide range of granular products, from coffee beans to pet food to fertilizer. This means that you can use the same equipment for multiple products, saving time and money on equipment changes and set-up.

In addition to increased efficiency and versatility, a granules multi heads filling canning line also offers improved accuracy and quality control. The automated filling process eliminates human error and ensures that each can is filled to the precise weight and volume required. This not only improves the quality of your product but also reduces the risk of costly recalls due to under or overfilled cans.

To further optimize production efficiency with a granules multi heads filling canning line, it is important to properly maintain and calibrate the equipment. Regular maintenance checks and calibration ensure that the machine is operating at peak performance, reducing downtime and preventing costly breakdowns. Additionally, training your staff on how to operate and maintain the equipment will help maximize its efficiency and longevity.

When investing in a granules multi heads filling canning line, it is important to consider the specific needs of your production line. Factors such as the size of your operation, the type of products you are filling, and your budget will all play a role in determining the best equipment for your needs. Consulting with a knowledgeable supplier or manufacturer can help you choose the right machine for your specific requirements.

In conclusion, a granules multi heads filling canning line is a valuable investment for any manufacturer looking to optimize production efficiency. By increasing output, improving accuracy, and reducing waste, this advanced equipment can help you stay competitive in today’s fast-paced market. Proper maintenance and training are essential for maximizing the benefits of this machinery, so be sure to invest the time and resources needed to ensure its success in your production line.

Case Studies: Successful Implementation of Granules Multi Heads Filling Canning Line in Various Industries

Granules multi heads filling canning lines have become a popular choice for many industries looking to streamline their production processes. These advanced machines are designed to efficiently fill containers with granular products such as grains, seeds, nuts, and more. With multiple filling heads, these canning lines can fill multiple containers simultaneously, increasing productivity and reducing downtime.

One successful implementation of a granules multi heads filling canning line can be seen in the food industry. Food manufacturers often deal with a high volume of granular products that need to be packaged quickly and efficiently. By investing in a granules multi heads filling canning line, these manufacturers have been able to significantly increase their production output while maintaining a high level of accuracy and consistency in their packaging.

Another industry that has seen success with granules multi heads filling canning lines is the pharmaceutical industry. Pharmaceutical companies often need to package granular medications in precise quantities to ensure the safety and efficacy of their products. By using a granules multi heads filling canning line, these companies have been able to automate the packaging process, reducing the risk of human error and ensuring that each container is filled with the correct amount of medication.

In the agricultural industry, granules multi heads filling canning lines have also proven to be a valuable asset. Seed manufacturers, for example, rely on these machines to quickly and accurately fill seed packets with a variety of different seeds. By using a granules multi heads filling canning line, these manufacturers have been able to increase their production capacity and meet the growing demand for their products.

One of the key benefits of granules multi heads filling canning lines is their versatility. These machines can be easily adjusted to accommodate different container sizes and fill weights, making them suitable for a wide range of products and industries. This flexibility allows manufacturers to quickly adapt to changing market demands and maintain a competitive edge in their industry.

Furthermore, granules multi heads filling canning lines are designed to be user-friendly and easy to maintain. With intuitive controls and minimal downtime for maintenance, these machines are a cost-effective solution for manufacturers looking to improve their production processes. Additionally, many granules multi heads filling canning lines are equipped with advanced technology such as automatic weighing systems and quality control sensors, further enhancing their efficiency and accuracy.

Overall, the successful implementation of granules multi heads filling canning lines in various industries highlights the importance of investing in advanced packaging technology. These machines offer a range of benefits, from increased productivity and efficiency to improved accuracy and consistency in packaging. As industries continue to evolve and grow, granules multi heads filling canning lines will undoubtedly play a crucial role in helping manufacturers meet the demands of the market and stay ahead of the competition.