Table of Contents

Increased Efficiency in Snack Packaging with Automatic Double Heads Capping Machine

In the fast-paced world of snack packaging, efficiency is key. With consumers demanding convenience and quick access to their favorite treats, snack manufacturers are constantly looking for ways to streamline their production processes. One solution that has gained popularity in recent years is the automatic double heads capping machine.

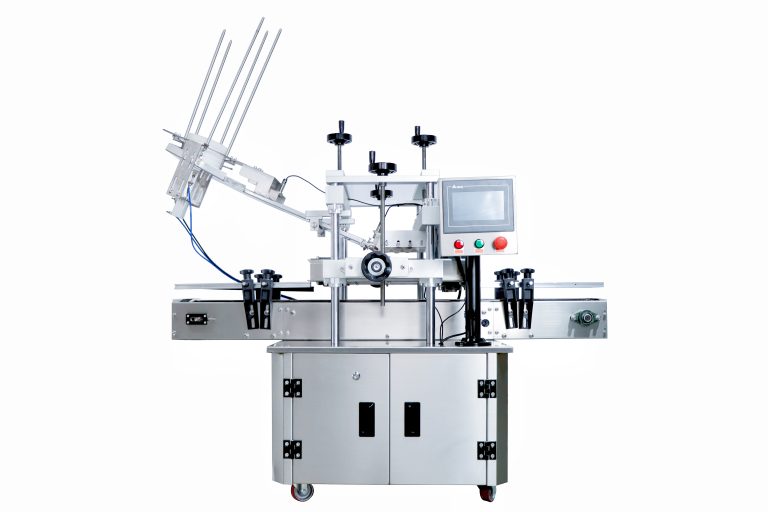

This innovative piece of equipment is designed to cap snack cans with precision and speed, allowing manufacturers to increase their output and meet the growing demand for their products. By automating the capping process, companies can reduce the risk of human error and ensure that each can is sealed properly before it is shipped out to retailers.

One of the key benefits of the automatic double heads capping machine is its ability to cap multiple cans simultaneously. This means that manufacturers can cap twice as many cans in the same amount of time, effectively doubling their production capacity. This increased efficiency allows companies to meet tight deadlines and fulfill large orders without sacrificing quality.

In addition to its speed and precision, the automatic double heads capping machine also offers a high level of flexibility. Manufacturers can easily adjust the machine to accommodate different can sizes and shapes, making it suitable for a wide range of snack products. This versatility allows companies to switch between different packaging formats quickly and efficiently, saving time and reducing downtime.

Another advantage of the automatic double heads capping machine is its ease of use. With intuitive controls and a user-friendly interface, operators can quickly learn how to operate the machine and make adjustments as needed. This reduces the need for extensive training and allows companies to get up and running with the machine in no time.

Furthermore, the automatic double heads capping machine is designed to be durable and reliable. Built to withstand the rigors of continuous use, this machine is a long-term investment that can help companies improve their production processes for years to come. With regular maintenance and proper care, manufacturers can expect the machine to perform consistently and reliably, ensuring that their snack packaging operations run smoothly.

Overall, the automatic double heads capping machine is a valuable tool for snack manufacturers looking to increase efficiency and streamline their production processes. By automating the capping process, companies can save time, reduce costs, and improve the quality of their products. With its speed, precision, flexibility, ease of use, and durability, this machine is a smart investment for any company looking to stay ahead in the competitive snack packaging industry.

How Automatic Snack Cans Capping Machine Improves Productivity and Quality Control

In the fast-paced world of snack production, efficiency and quality control are paramount. One way to streamline the packaging process and ensure consistency in product sealing is through the use of automatic snack cans double heads capping machines. These machines are designed to cap snack cans quickly and accurately, reducing the risk of human error and improving overall productivity.

One of the key benefits of using an automatic snack cans capping machine is the speed at which it can cap cans. With two heads working simultaneously, these machines can cap a large number of cans in a short amount of time, significantly increasing production output. This is especially important in industries where demand for snack products is high and production needs to be efficient to keep up with consumer demand.

In addition to speed, automatic capping machines also offer improved quality control. By automating the capping process, manufacturers can ensure that each can is sealed properly and consistently. This reduces the risk of leaks or contamination, which can lead to product spoilage and customer dissatisfaction. With precise torque control and adjustable capping pressure, these machines can be customized to meet the specific requirements of different snack products, ensuring a tight and secure seal every time.

Furthermore, automatic capping machines are easy to operate and require minimal training. This means that manufacturers can quickly integrate these machines into their production line without the need for extensive downtime or retraining of staff. The user-friendly interface allows operators to adjust settings and monitor the capping process with ease, making it simple to maintain consistent quality control standards.

Another advantage of automatic snack cans capping machines is their versatility. These machines can cap a wide range of can sizes and shapes, making them suitable for use in various snack production facilities. Whether manufacturers are packaging nuts, chips, or other snack items, these machines can be adapted to meet the specific requirements of different products. This flexibility allows manufacturers to streamline their packaging process and improve overall efficiency.

In conclusion, automatic snack cans double heads capping machines offer a range of benefits for snack manufacturers looking to improve productivity and quality control. By automating the capping process, these machines can cap cans quickly and accurately, reducing the risk of human error and ensuring consistent sealing. With easy operation, versatility, and customizable settings, these machines are a valuable addition to any snack production line. By investing in automatic capping machines, manufacturers can increase production output, reduce waste, and maintain high-quality standards, ultimately improving their bottom line.

The Future of Snack Packaging: Advantages of Investing in Automatic Double Heads Capping Machine

In the fast-paced world of snack packaging, efficiency and speed are key factors in meeting consumer demands. As technology continues to advance, the use of automatic double heads capping machines is becoming increasingly popular in the snack industry. These machines offer a range of advantages that can greatly benefit snack manufacturers looking to streamline their packaging processes and improve overall productivity.

One of the main advantages of investing in an automatic double heads capping machine is the significant increase in production speed. These machines are designed to cap multiple snack cans simultaneously, reducing the time it takes to complete the packaging process. This not only allows manufacturers to meet tight production deadlines but also ensures a consistent and uniform capping process, resulting in a higher quality end product.

Furthermore, automatic double heads capping machines are equipped with advanced technology that allows for precise and accurate capping. This ensures that each snack can is securely sealed, preventing any leaks or contamination. The use of these machines also reduces the risk of human error, as the capping process is automated and controlled by the machine’s software. This results in a more reliable and efficient packaging process, ultimately leading to cost savings for manufacturers.

In addition to increased production speed and accuracy, automatic double heads capping machines also offer versatility in terms of the types of snack cans they can cap. These machines are designed to accommodate a wide range of can sizes and shapes, making them suitable for various snack products. This flexibility allows manufacturers to easily switch between different packaging formats without the need for extensive retooling or adjustments, saving time and resources.

Another key advantage of investing in an automatic double heads capping machine is the reduction in labor costs. By automating the capping process, manufacturers can significantly reduce the need for manual labor, freeing up employees to focus on other tasks within the production line. This not only improves overall efficiency but also minimizes the risk of injuries or accidents associated with manual capping processes.

Furthermore, automatic double heads capping machines are designed to be user-friendly and easy to operate. Manufacturers can easily program the machine to meet their specific capping requirements, and the intuitive interface allows for quick adjustments and troubleshooting. This ensures that operators can quickly adapt to changing production needs and maintain a smooth and efficient packaging process.

Overall, investing in an automatic double heads capping machine offers numerous advantages for snack manufacturers looking to improve their packaging processes. From increased production speed and accuracy to reduced labor costs and improved versatility, these machines are a valuable asset for any snack packaging operation. As technology continues to advance, the use of automated packaging equipment will become increasingly essential in meeting the demands of the modern snack industry. By investing in these machines, manufacturers can stay ahead of the competition and ensure the success of their snack products in the market.