Table of Contents

Benefits of Using a Fully Automatic Screw Capping Machine for Glass Jars

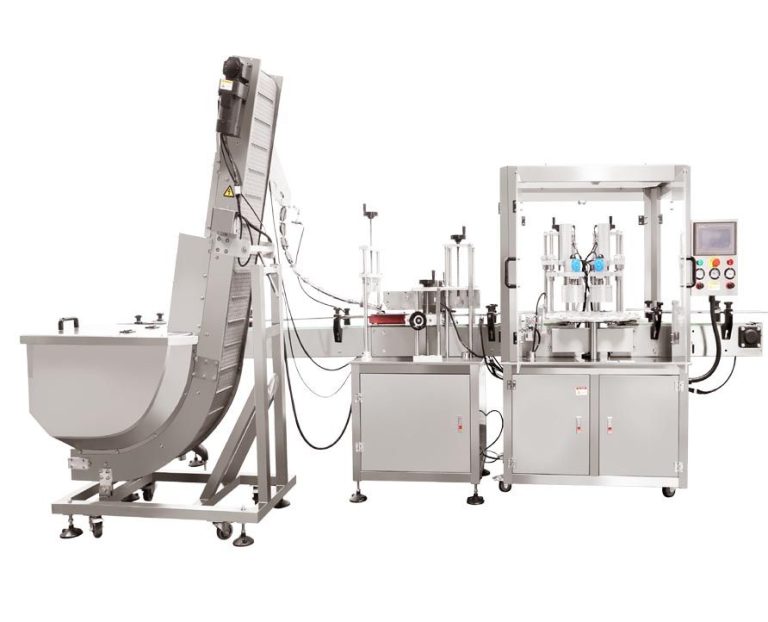

Glass jars are a popular choice for packaging various products, from food items like jams and sauces to beauty products like creams and lotions. One of the key components of a glass jar is its cap, which not only seals the contents inside but also plays a crucial role in maintaining the product’s freshness and quality. In recent years, fully automatic screw capping machines have become increasingly popular for sealing glass jars efficiently and effectively.

One of the main benefits of using a fully automatic screw capping machine for glass jars is its speed and efficiency. These machines are designed to cap jars quickly and accurately, significantly reducing the time and labor required for the packaging process. With a fully automatic screw capping machine, manufacturers can cap hundreds of jars per minute, increasing production output and overall efficiency.

In addition to speed, fully automatic screw capping machines also offer consistent and precise capping results. These machines are equipped with advanced technology that ensures each jar is capped with the right amount of torque, preventing leaks and ensuring a tight seal. This level of precision is crucial for maintaining the quality and integrity of the product inside the jar, as well as for meeting industry standards and regulations.

Furthermore, fully automatic screw capping machines are versatile and can be easily adjusted to accommodate different jar sizes and cap types. This flexibility allows manufacturers to use the same machine for a variety of products, saving time and resources that would otherwise be spent on switching between different machines. Additionally, these machines are easy to operate and require minimal training, making them a cost-effective solution for businesses of all sizes.

Another key benefit of using a fully automatic screw capping machine for glass jars is its reliability and durability. These machines are built to withstand the rigors of continuous use in a production environment, ensuring consistent performance and minimal downtime. With regular maintenance and proper care, a fully automatic screw capping machine can last for years, providing a reliable and efficient solution for sealing glass jars.

In conclusion, fully automatic screw capping machines offer a range of benefits for businesses that package products in glass jars. From increased speed and efficiency to precise and consistent capping results, these machines are a valuable investment for manufacturers looking to streamline their packaging process and improve overall productivity. With their versatility, reliability, and durability, fully automatic screw capping machines are an essential tool for businesses looking to stay competitive in today’s fast-paced market.

How to Choose the Right Fully Automatic Screw Capping Machine for Your Glass Jar Packaging Line

When it comes to packaging products in glass jars, having the right equipment is essential to ensure efficiency and consistency in the packaging process. One key piece of equipment that can greatly improve the efficiency of your glass jar packaging line is a fully automatic screw capping machine. These machines are designed to quickly and accurately apply screw caps to glass jars, saving time and labor costs while ensuring a secure seal on each jar.

When choosing a fully automatic screw capping machine for your glass jar packaging line, there are several factors to consider to ensure you select the right machine for your specific needs. One of the first things to consider is the speed and capacity of the machine. Depending on the volume of jars you need to cap per hour, you will want to choose a machine that can keep up with your production demands. Look for a machine that offers a high speed and can handle the capacity you require to keep your packaging line running smoothly.

Another important factor to consider when choosing a fully automatic screw capping machine is the size and shape of the jars you will be capping. Some machines are designed to handle a specific range of jar sizes and shapes, so it is important to choose a machine that is compatible with the jars you will be using in your packaging line. Make sure to consider the diameter and height of the jars, as well as any unique features such as handles or ridges that may affect the capping process.

In addition to speed and compatibility with jar sizes, it is also important to consider the level of automation and customization options available with the machine. Fully automatic screw capping machines come in a range of configurations, from basic models that require minimal operator intervention to more advanced models that offer features such as automatic cap sorting and feeding, torque adjustment, and cap inspection systems. Consider the level of automation you require for your packaging line and choose a machine that offers the right balance of automation and customization options to meet your specific needs.

When researching fully automatic screw capping machines, be sure to consider the reputation and reliability of the manufacturer. Look for a manufacturer with a proven track record of producing high-quality machines that are built to last. Read customer reviews and testimonials to get an idea of the machine’s performance and reliability in real-world packaging environments. Choosing a machine from a reputable manufacturer will help ensure that you are investing in a reliable piece of equipment that will provide years of trouble-free operation.

In conclusion, choosing the right fully automatic screw capping machine for your glass jar packaging line is essential to ensure efficiency, consistency, and reliability in the packaging process. Consider factors such as speed, compatibility with jar sizes, level of automation, and manufacturer reputation when selecting a machine for your packaging line. By taking the time to research and choose the right machine for your specific needs, you can improve the efficiency and quality of your glass jar packaging process.