Table of Contents

Benefits of Using Nutritional Powder Paper Can Packing Machine Line

In the fast-paced world of food production, efficiency and accuracy are key factors in ensuring that products are packaged and delivered in a timely manner. One of the most important aspects of this process is the packaging of nutritional powder products, which require careful handling to maintain their quality and freshness. This is where a nutritional powder paper can packing machine line comes into play, offering a range of benefits that can help streamline the packaging process and improve overall productivity.

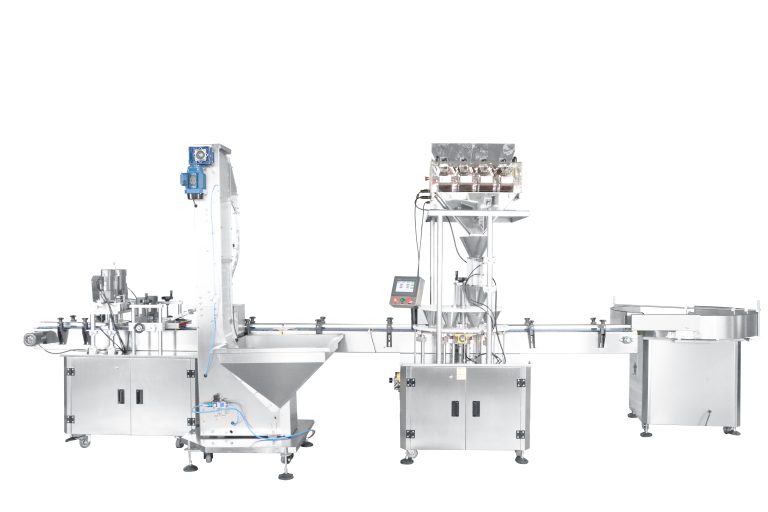

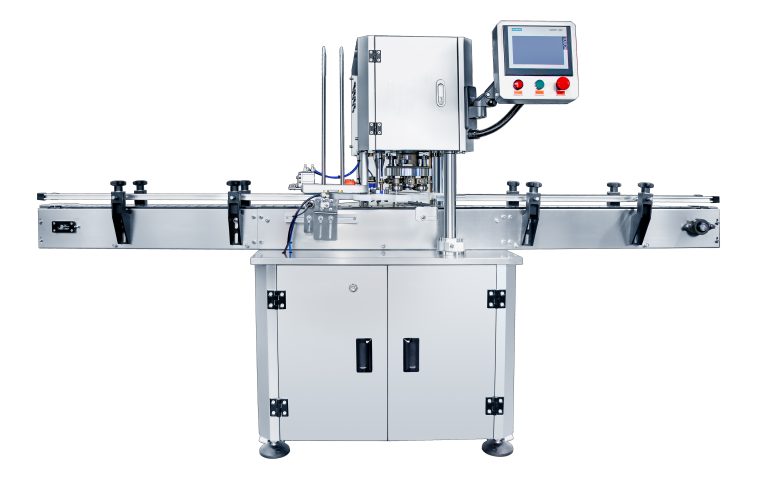

One of the primary benefits of using a nutritional powder paper can packing machine line is the level of automation it provides. These machines are designed to handle the entire packaging process from start to finish, including filling, sealing, and labeling the cans. This automation not only reduces the need for manual labor, but also ensures a consistent and uniform packaging process, resulting in a higher quality end product.

Additionally, nutritional powder paper can packing machine lines are equipped with advanced technology that allows for precise measurement and filling of the cans. This ensures that each can is filled to the exact specifications, reducing waste and ensuring that customers receive the correct amount of product every time. This level of accuracy is crucial in the food industry, where even small variations in product weight can have a significant impact on quality and customer satisfaction.

Another key benefit of using a nutritional powder paper can packing machine line is the speed at which it can operate. These machines are capable of packaging a large number of cans in a relatively short amount of time, significantly increasing production output and reducing bottlenecks in the packaging process. This can be especially beneficial for companies that have high demand for their products and need to meet tight deadlines for delivery.

In addition to improving efficiency and accuracy, nutritional powder paper can packing machine lines also offer a range of other benefits. For example, these machines are designed to be easy to clean and maintain, reducing downtime and ensuring that they can operate at peak performance for extended periods of time. This can help companies save money on maintenance costs and avoid costly production delays.

Furthermore, nutritional powder paper can packing machine lines are versatile and can be customized to meet the specific needs of different products and packaging requirements. Whether companies are packaging powders, granules, or other types of nutritional products, these machines can be adjusted to accommodate a wide range of product sizes and packaging materials. This flexibility allows companies to adapt to changing market demands and stay ahead of the competition.

Overall, the benefits of using a nutritional powder paper can packing machine line are clear. From improved efficiency and accuracy to increased production output and versatility, these machines offer a range of advantages that can help companies streamline their packaging process and deliver high-quality products to customers. By investing in this technology, companies can stay competitive in the fast-paced world of food production and ensure that their products are packaged and delivered with precision and care.

How to Choose the Right Nutritional Powder Paper Can Packing Machine Line for Your Business

In the world of packaging machinery, there are many options available for businesses looking to streamline their production processes. One popular choice for companies in the food and beverage industry is the nutritional powder paper can packing machine line. This type of equipment is designed to efficiently package powdered nutritional supplements, protein powders, and other similar products into paper cans for retail sale.

When choosing the right nutritional powder paper can packing machine line for your business, there are several factors to consider. First and foremost, you’ll want to think about the size and capacity of the machine. Depending on the volume of product you need to package, you may need a machine with a higher output capacity. It’s important to choose a machine that can keep up with your production demands without causing bottlenecks in your workflow.

Another important consideration when selecting a nutritional powder paper can packing machine line is the level of automation it offers. Some machines are fully automated, meaning they can handle the entire packaging process from start to finish with minimal human intervention. This can help increase efficiency and reduce the risk of errors in the packaging process. However, fully automated machines tend to be more expensive than semi-automated or manual machines, so you’ll need to weigh the cost against the benefits of automation for your business.

In addition to capacity and automation, you’ll also want to consider the flexibility of the machine. Can it handle different sizes of paper cans? Can it accommodate different types of nutritional powders, such as whey protein, plant-based protein, or meal replacement powders? A machine that offers flexibility in terms of packaging options can help you adapt to changing market demands and expand your product offerings in the future.

When evaluating different nutritional powder paper can packing machine lines, it’s also important to consider the level of customization and support offered by the manufacturer. Look for a company that can tailor the machine to your specific needs and provide ongoing support and maintenance to keep your equipment running smoothly. A reliable manufacturer will also offer training for your staff to ensure they can operate the machine safely and efficiently.

Finally, don’t forget to consider the overall cost of the machine, including installation, maintenance, and operating costs. While it’s important to invest in quality equipment that will help your business grow, you’ll also need to ensure that the machine fits within your budget constraints. Compare quotes from different manufacturers and consider the long-term return on investment when making your decision.

In conclusion, choosing the right nutritional powder paper can packing machine line for your business is a crucial decision that can impact your production efficiency and bottom line. By considering factors such as capacity, automation, flexibility, customization, and cost, you can select a machine that meets your specific needs and helps your business thrive in the competitive food and beverage market. Take the time to research different options and consult with industry experts to make an informed decision that will benefit your business for years to come.

Tips for Maintaining and Cleaning Nutritional Powder Paper Can Packing Machine Line

Nutritional powder paper can packing machines are essential equipment in the food packaging industry. They are used to efficiently pack nutritional powder into paper cans, ensuring that the product remains fresh and protected from external contaminants. To ensure the smooth operation of these machines and maintain the quality of the packed products, regular maintenance and cleaning are crucial.

One of the most important tips for maintaining a nutritional powder paper can packing machine line is to follow the manufacturer’s guidelines for maintenance. This includes regular inspections, lubrication of moving parts, and replacement of worn-out components. By following these guidelines, you can prevent breakdowns and ensure that the machine operates at its optimal efficiency.

In addition to following the manufacturer’s guidelines, it is also important to establish a regular maintenance schedule for the machine line. This can include daily, weekly, and monthly maintenance tasks to keep the machine in top condition. Regular maintenance not only prolongs the lifespan of the machine but also helps to prevent costly repairs and downtime.

When it comes to cleaning the nutritional powder paper can packing machine line, it is important to use the right cleaning agents and techniques. The machine should be cleaned regularly to remove any residue or buildup that can affect the quality of the packed products. It is recommended to use food-grade cleaning agents and sanitizers to ensure that the machine is free from contaminants.

Another important tip for maintaining and cleaning the machine line is to pay attention to the seals and gaskets. These components play a crucial role in preventing leaks and ensuring that the packed products remain fresh. Regularly inspecting and replacing worn-out seals and gaskets can help to prevent product contamination and ensure the integrity of the packaging.

Proper storage of the machine line is also essential for maintaining its quality and performance. The machine should be stored in a clean and dry environment to prevent rust and corrosion. It is also important to cover the machine when not in use to protect it from dust and debris.

Regular training of operators is another important aspect of maintaining a nutritional powder paper can packing machine line. Operators should be trained on how to operate the machine safely and efficiently, as well as how to perform basic maintenance tasks. By investing in training for operators, you can ensure that the machine is used correctly and that any issues are addressed promptly.

In conclusion, maintaining and cleaning a nutritional powder paper can packing machine line is essential for ensuring the quality of the packed products and prolonging the lifespan of the equipment. By following the manufacturer’s guidelines, establishing a regular maintenance schedule, using the right cleaning agents, and training operators, you can keep your machine line in top condition. With proper maintenance and cleaning, you can ensure that your nutritional powder paper can packing machine line operates smoothly and efficiently, delivering high-quality products to your customers.