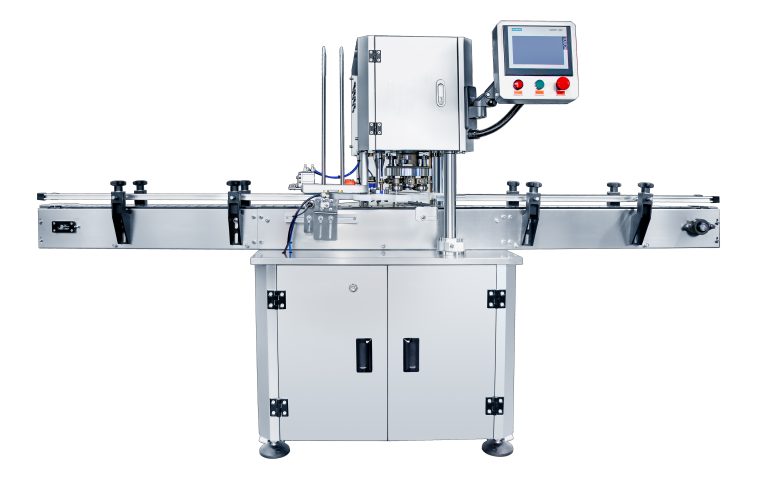

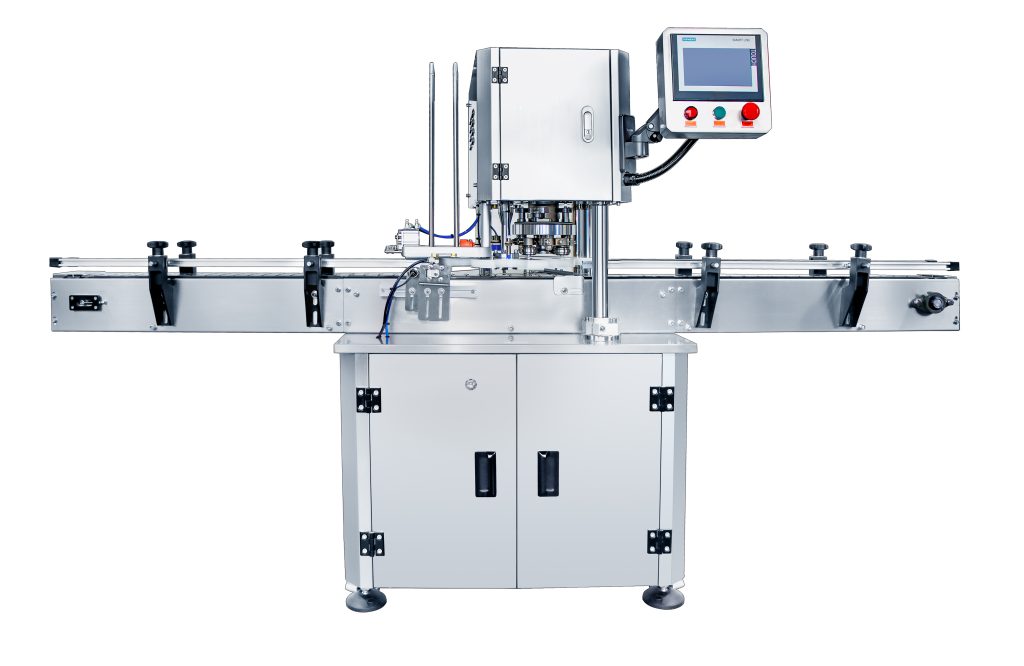

In the realm of can closing technology, Automatic Servo Can Closers stand out for their unrivaled precision. These advanced machines have raised the bar when it comes to achieving flawless and consistent closures.

The level of accuracy offered by Automatic Servo Can Closers is truly remarkable. Every movement, every application of force is precisely controlled and calibrated to ensure that each can is sealed with absolute perfection. This means no leaks, no weak seals, and a product that is protected from the elements and ready for the market.

The key to this precision lies in the sophisticated servo technology incorporated into these closers. The ability to fine-tune the closing parameters allows for customization based on the specific requirements of different can types and contents. Whether it’s a delicate food product or a hazardous chemical, the Automatic Servo Can Closer can be adjusted to provide the ideal seal.

Not only does this precision enhance the quality and safety of the packaged goods, but it also boosts the efficiency of the production line. With fewer rejects and less need for rework, manufacturers can save time and resources, increasing overall productivity.

Moreover, the consistent precision delivered by these closers helps build trust among consumers. A well-sealed can gives the impression of a high-quality product, which in turn leads to customer satisfaction and brand loyalty.

In summary, Automatic Servo Can Closers represent the pinnacle of precision in the world of can closing. Their ability to provide exact and reliable seals makes them an indispensable tool for industries that rely on can packaging to deliver their products safely and effectively.