Table of Contents

Benefits of Using Single Head Milk Powder Metal Can Filling Machine

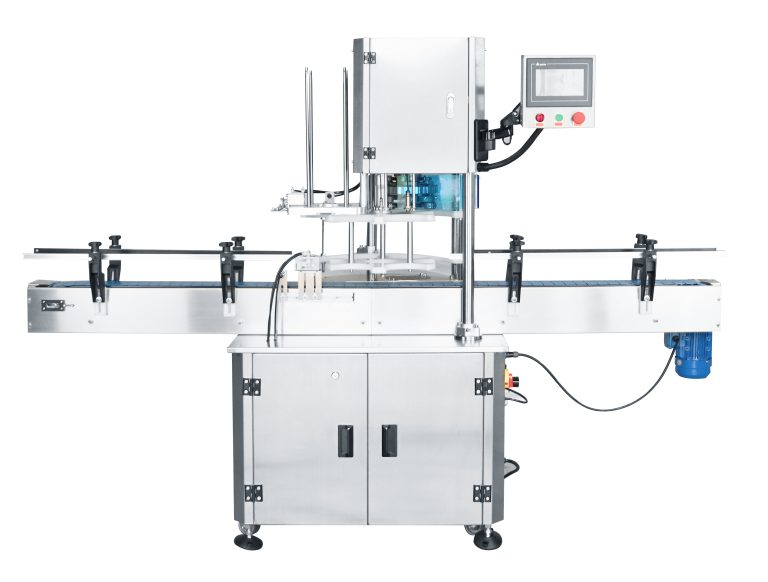

In the food and beverage industry, efficiency and accuracy are key factors in ensuring the quality of products. When it comes to filling metal cans with milk powder, using a single head milk powder metal can filling machine can offer numerous benefits. This article will explore the advantages of using this type of machine in the production process.

One of the main benefits of using a single head milk powder metal can filling machine is its ability to accurately fill cans with the desired amount of milk powder. These machines are equipped with advanced technology that allows for precise measurements, ensuring that each can is filled to the correct weight. This level of accuracy is essential in maintaining consistency in product quality and meeting regulatory standards.

Additionally, single head milk powder metal can filling machines are designed to operate at high speeds, increasing the overall efficiency of the production process. With the ability to fill multiple cans in a short amount of time, these machines can help manufacturers meet high demand and maximize output. This can result in cost savings and increased profitability for businesses.

Another advantage of using a single head milk powder metal can filling machine is its versatility. These machines can be easily adjusted to accommodate different can sizes and fill volumes, making them suitable for a variety of production needs. This flexibility allows manufacturers to adapt to changing market demands and produce a wide range of products with ease.

Furthermore, single head milk powder metal can filling machines are designed with hygiene and safety in mind. These machines are constructed from high-quality materials that are easy to clean and maintain, reducing the risk of contamination and ensuring product safety. Additionally, many machines are equipped with features such as automatic cleaning systems and sanitary design elements to further enhance food safety standards.

In addition to the benefits mentioned above, using a single head milk powder metal can filling machine can also improve overall production efficiency. These machines are equipped with advanced control systems that monitor and adjust filling parameters in real-time, reducing the risk of errors and minimizing product waste. This level of automation can streamline the production process and improve overall workflow.

Overall, the use of a single head milk powder metal can filling machine offers numerous benefits for manufacturers in the food and beverage industry. From increased accuracy and efficiency to versatility and safety, these machines are an essential tool for ensuring high-quality products and meeting production demands. By investing in this type of equipment, businesses can improve their operations and stay competitive in the market.

How to Choose the Right Single Head Milk Powder Metal Can Filling Machine for Your Business

When it comes to packaging milk powder in metal cans, having the right filling machine is crucial for ensuring efficiency and accuracy in your production process. A single head milk powder metal can filling machine is a popular choice for many businesses due to its simplicity and ease of use. However, with so many options available on the market, it can be overwhelming to choose the right one for your specific needs. In this article, we will discuss some key factors to consider when selecting a single head milk powder metal can filling machine for your business.

First and foremost, it is important to consider the capacity of the filling machine. The capacity of the machine will determine how many cans it can fill in a given amount of time. If you have a high-volume production line, you will need a machine with a larger capacity to keep up with demand. On the other hand, if you have a smaller operation, a machine with a lower capacity may be more suitable. It is important to carefully assess your production needs and choose a machine that can meet those requirements.

Another important factor to consider is the accuracy of the filling machine. Precision is key when filling metal cans with milk powder, as even a small deviation in the amount of powder can affect the quality of the final product. Look for a machine that offers precise control over the filling process, such as adjustable filling speeds and accurate measurement systems. This will help ensure that each can is filled with the correct amount of powder, leading to consistent and high-quality products.

In addition to capacity and accuracy, it is also important to consider the ease of use and maintenance of the filling machine. A machine that is easy to operate and maintain will save you time and effort in the long run. Look for features such as intuitive controls, easy-to-clean components, and quick changeover capabilities. This will help streamline your production process and minimize downtime due to maintenance or repairs.

Furthermore, consider the overall build quality and durability of the filling machine. A machine that is built to last will provide you with years of reliable service, saving you money on repairs and replacements in the future. Look for machines made from high-quality materials, such as stainless steel, that can withstand the rigors of daily use in a production environment. Additionally, consider the reputation of the manufacturer and read reviews from other customers to ensure that you are investing in a reliable and well-built machine.

In conclusion, choosing the right single head milk powder metal can filling machine for your business is a decision that should not be taken lightly. Consider factors such as capacity, accuracy, ease of use, maintenance, and build quality when making your decision. By carefully assessing your production needs and researching different options, you can select a machine that will help streamline your production process and ensure consistent and high-quality products. Investing in a quality filling machine is an investment in the success of your business.

Maintenance Tips for Single Head Milk Powder Metal Can Filling Machine

Maintaining a single head milk powder metal can filling machine is essential to ensure its optimal performance and longevity. Regular maintenance not only helps prevent breakdowns and costly repairs but also ensures the quality and safety of the milk powder being filled. In this article, we will discuss some important maintenance tips for a single head milk powder metal can filling machine.

First and foremost, it is crucial to clean the machine regularly. Milk powder can leave residue and build-up on the machine’s components, which can affect its performance and contaminate the product. Use a mild detergent and warm water to clean the machine thoroughly, paying special attention to areas where milk powder tends to accumulate. Make sure to rinse the machine thoroughly after cleaning to remove any detergent residue.

In addition to regular cleaning, it is important to lubricate the machine’s moving parts to prevent friction and wear. Use a food-grade lubricant recommended by the manufacturer and apply it to the machine’s bearings, gears, and other moving parts according to the manufacturer’s instructions. Over-lubrication can attract dust and debris, so be sure to use the right amount of lubricant.

Inspect the machine’s seals and gaskets regularly for signs of wear or damage. Damaged seals and gaskets can lead to leaks and contamination of the milk powder. Replace any worn or damaged seals and gaskets promptly to prevent issues down the line. It is also important to check the machine’s belts and chains for wear and tension. Loose or worn belts and chains can affect the machine’s performance and lead to breakdowns.

Regularly check the machine’s sensors and controls to ensure they are functioning properly. Sensors play a crucial role in ensuring the accurate filling of milk powder into cans. Clean the sensors regularly to prevent dust and debris from interfering with their operation. Test the machine’s controls to make sure they are responding correctly and calibrate them if necessary.

Inspect the machine’s electrical components for signs of wear or damage. Loose connections, frayed wires, or damaged components can pose a safety hazard and affect the machine’s performance. Replace any damaged electrical components promptly and tighten any loose connections to prevent issues.

Finally, it is important to keep a record of the machine’s maintenance schedule and any repairs or replacements that have been done. This will help you track the machine’s performance over time and identify any recurring issues that need to be addressed. Regular maintenance and record-keeping are key to ensuring the longevity and optimal performance of a single head milk powder metal can filling machine.

In conclusion, maintaining a single head milk powder metal can filling machine is essential to ensure its optimal performance and longevity. Regular cleaning, lubrication, inspection of seals and gaskets, checking sensors and controls, inspecting belts and chains, and monitoring electrical components are all important aspects of machine maintenance. By following these maintenance tips, you can ensure the quality and safety of the milk powder being filled and prevent breakdowns and costly repairs.