In the world of tomato paste production, the tomato paste tin can filling and seaming machine is a crucial piece of equipment.

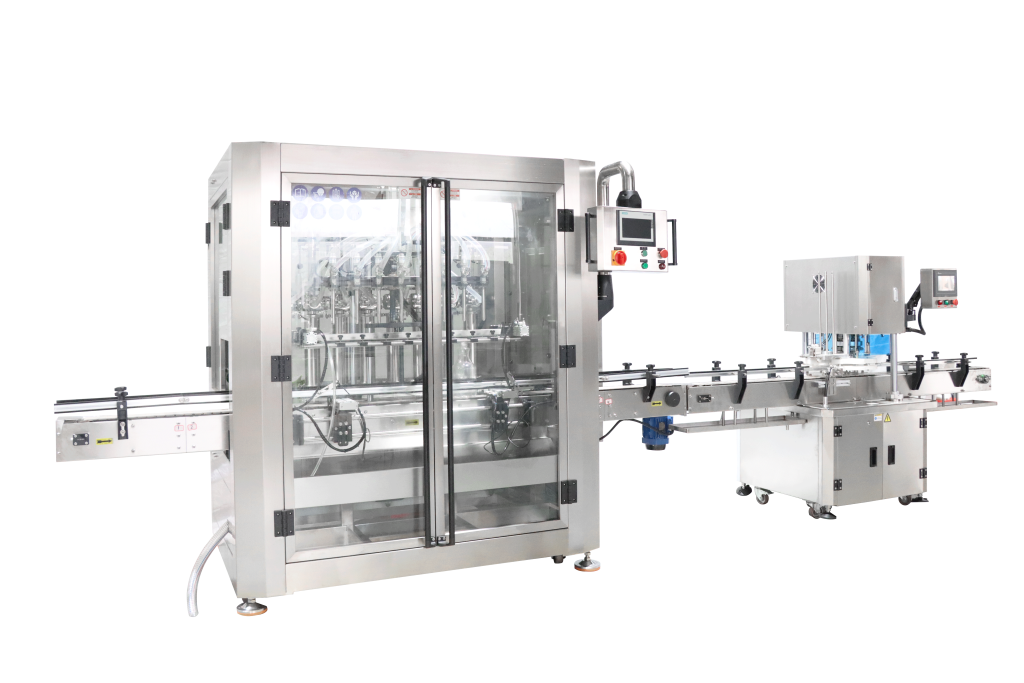

This specialized machine plays a vital role in ensuring the quality and shelf life of tomato paste. The filling process is designed with precision to accurately measure and deposit the right amount of paste into each tin can, minimizing waste and ensuring consistent product quantities.

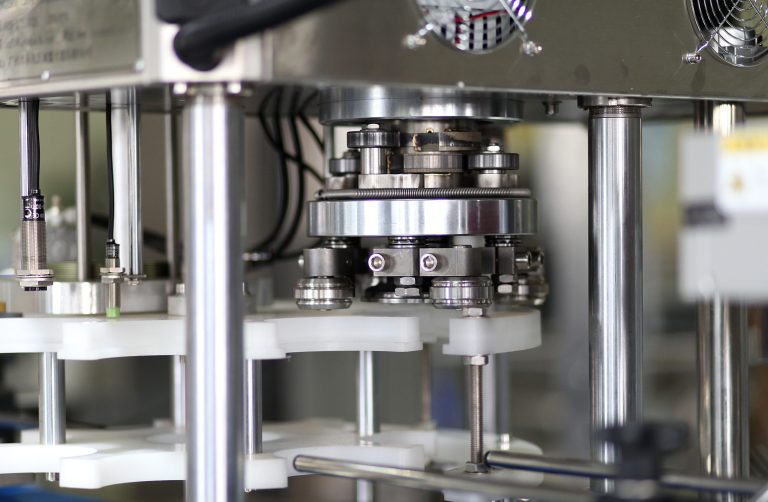

The seaming function is equally important as it creates a tight and secure seal that protects the tomato paste from air, moisture, and contaminants. This helps to maintain the freshness, flavor, and nutritional value of the paste for an extended period.

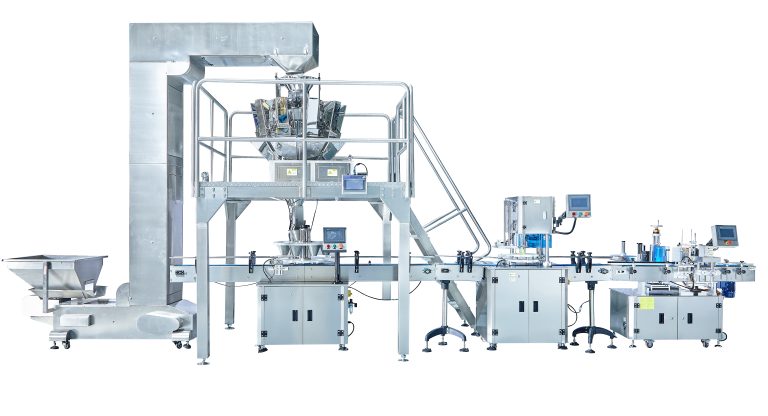

One of the significant advantages of this machine is its speed and productivity. It can handle a large volume of tin cans in a relatively short time, meeting the demands of both small-scale artisanal producers and large industrial operations.

The machine is also engineered to maintain hygiene and safety standards. It is constructed with materials that are easy to clean and sanitize, reducing the risk of contamination and ensuring that the tomato paste meets strict quality regulations.

In addition, it offers flexibility in terms of can sizes and types, allowing producers to adapt to different market requirements and packaging preferences.

The automated nature of the filling and seaming process reduces the reliance on manual labor, minimizing the potential for human error and increasing overall operational efficiency.

Regular maintenance and calibration of the machine are essential to ensure its continued accurate performance and longevity.

Overall, the tomato paste tin can filling and seaming machine is an indispensable tool in the tomato processing industry, contributing to the delivery of high-quality tomato paste to consumers.

Stay tuned to our blogs for more detailed insights into the latest advancements and best practices in food packaging machinery!

-768x622.jpg)