Table of Contents

Benefits of Using High Volume Fully Auto Round Can Sealing Machine

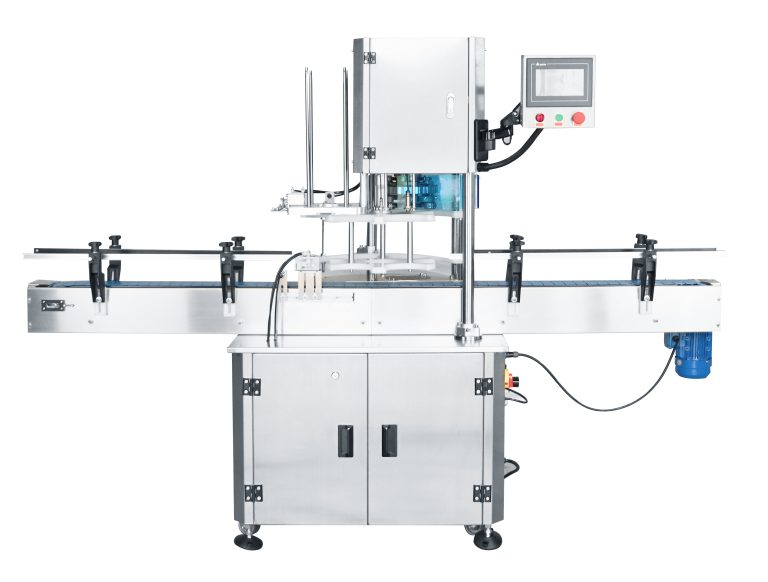

In the world of manufacturing and packaging, efficiency is key. Companies are constantly looking for ways to streamline their processes and increase productivity. One way to achieve this is by investing in high volume fully auto round can sealing machines. These machines are designed to quickly and efficiently seal cans of various sizes, making them an essential tool for businesses that deal with large quantities of canned goods.

One of the main benefits of using a high volume fully auto round can sealing machine is the speed at which it operates. These machines are capable of sealing hundreds of cans per minute, significantly reducing the time it takes to package products. This increased speed allows companies to meet tight deadlines and fulfill orders in a timely manner, ultimately improving customer satisfaction.

In addition to speed, high volume fully auto round can sealing machines also offer a high level of precision. These machines are equipped with advanced technology that ensures each can is sealed with precision and accuracy. This helps to minimize the risk of leaks or contamination, ensuring that products remain fresh and safe for consumption.

Another benefit of using a high volume fully auto round can sealing machine is the cost savings it provides. By automating the sealing process, companies can reduce the need for manual labor, ultimately lowering labor costs. Additionally, these machines are designed to be highly efficient, reducing waste and maximizing productivity. This results in overall cost savings for businesses, making the investment in a high volume fully auto round can sealing machine a smart financial decision.

Furthermore, high volume fully auto round can sealing machines are incredibly versatile. These machines are capable of sealing cans of various sizes and materials, making them suitable for a wide range of products. Whether you are packaging food, beverages, or other goods, a high volume fully auto round can sealing machine can accommodate your needs.

In addition to their versatility, high volume fully auto round can sealing machines are also easy to operate and maintain. These machines are designed with user-friendly interfaces and intuitive controls, making them easy for operators to learn and use. Additionally, these machines are built to withstand the rigors of continuous use, requiring minimal maintenance and upkeep.

Overall, the benefits of using a high volume fully auto round can sealing machine are clear. From increased speed and precision to cost savings and versatility, these machines offer a wide range of advantages for businesses looking to streamline their packaging processes. By investing in a high volume fully auto round can sealing machine, companies can improve efficiency, reduce costs, and ultimately enhance their overall productivity.

How to Choose the Right High Volume Fully Auto Round Can Sealing Machine for Your Business

When it comes to choosing the right high volume fully auto round can sealing machine for your business, there are several factors to consider. These machines are essential for businesses that need to seal a large number of cans quickly and efficiently. With so many options available on the market, it can be overwhelming to decide which machine is the best fit for your specific needs.

One of the first things to consider when choosing a high volume fully auto round can sealing machine is the speed at which it can operate. These machines are designed to seal cans at a rapid pace, so it is important to choose a machine that can keep up with the demands of your business. Look for a machine that has a high sealing speed and can handle a large volume of cans per hour.

In addition to speed, it is also important to consider the size and capacity of the machine. Make sure to choose a machine that can accommodate the size of cans that you will be sealing. Some machines are designed to seal cans of a specific size, while others are more versatile and can handle a range of can sizes. Consider the volume of cans that you will be sealing on a daily basis and choose a machine that can meet your production needs.

Another important factor to consider when choosing a high volume fully auto round can sealing machine is the level of automation that is offered. Fully automatic machines are designed to operate with minimal human intervention, which can help to increase efficiency and reduce labor costs. Look for a machine that offers features such as automatic lid feeding, can feeding, and sealing to streamline the sealing process.

It is also important to consider the durability and reliability of the machine. Choose a machine that is built to last and can withstand the demands of a high-volume production environment. Look for a machine that is made from high-quality materials and has a reputation for reliability. It is also a good idea to choose a machine that comes with a warranty to protect your investment.

When choosing a high volume fully auto round can sealing machine, it is also important to consider the ease of maintenance and servicing. Look for a machine that is easy to clean and maintain, as this will help to prolong the life of the machine and ensure that it continues to operate at peak performance. Choose a machine that comes with clear instructions for maintenance and servicing, and consider purchasing a machine from a manufacturer that offers ongoing support and service.

In conclusion, choosing the right high volume fully auto round can sealing machine for your business is a crucial decision that can have a significant impact on your production efficiency and overall success. Consider factors such as speed, size, capacity, automation, durability, and maintenance when making your decision. By taking the time to research and compare different machines, you can find the perfect machine to meet your specific needs and help your business thrive.

Maintenance Tips for High Volume Fully Auto Round Can Sealing Machine

Maintaining a high volume fully automatic round can sealing machine is crucial to ensure its optimal performance and longevity. Regular maintenance not only prevents breakdowns and costly repairs but also helps in maintaining the quality of the sealed cans. In this article, we will discuss some essential maintenance tips for a high volume fully automatic round can sealing machine.

First and foremost, it is important to regularly clean the machine to prevent any build-up of debris or residue that can affect its performance. Use a mild detergent and water solution to clean the exterior and interior of the machine, paying special attention to the sealing components. Make sure to dry the machine thoroughly before using it again to prevent any water damage.

Inspect the sealing components regularly for any signs of wear and tear. Replace any damaged or worn parts immediately to prevent any leaks or improper sealing of the cans. It is also important to lubricate the moving parts of the machine regularly to ensure smooth operation. Use a food-grade lubricant to prevent any contamination of the sealed cans.

Calibrating the machine is another important maintenance task that should be done regularly. Check the pressure settings and adjust them as needed to ensure a proper seal on the cans. It is also important to check the temperature settings to ensure that the cans are sealed at the correct temperature. Improper calibration can result in leaks or improperly sealed cans.

Regularly inspect the electrical components of the machine for any signs of damage or wear. Check the wiring and connections for any loose or frayed wires and replace them if necessary. It is also important to check the sensors and switches to ensure they are functioning properly. Any malfunctioning electrical components should be replaced immediately to prevent any safety hazards.

In addition to regular maintenance tasks, it is important to follow the manufacturer’s guidelines for operating the machine. Avoid overloading the machine beyond its capacity as this can cause damage to the components. It is also important to use the correct size and type of cans for sealing to prevent any issues with the sealing process.

Lastly, it is important to keep a record of all maintenance tasks performed on the machine. This will help in tracking the maintenance schedule and identifying any recurring issues that need to be addressed. Keeping a maintenance log will also help in identifying any patterns of wear and tear on specific components that may need to be replaced.

In conclusion, maintaining a high volume fully automatic round can sealing machine is essential to ensure its optimal performance and longevity. By following these maintenance tips and guidelines, you can prevent breakdowns, costly repairs, and ensure the quality of the sealed cans. Regular cleaning, inspection, calibration, and following the manufacturer’s guidelines are key to keeping the machine in top condition. Remember to keep a record of all maintenance tasks performed to track the machine’s maintenance schedule and address any recurring issues promptly.