Single-head servo capping machines offer several ways to enhance packaging efficiency.

Firstly, their advanced servo technology ensures rapid and consistent capping actions. The machine can operate at high speeds without sacrificing the quality of the capping, allowing for a greater number of containers to be capped in a shorter period.

The precise control provided by the servo system means less time is wasted on redoing caps that aren’t properly sealed. This reduces the overall processing time and boosts productivity.

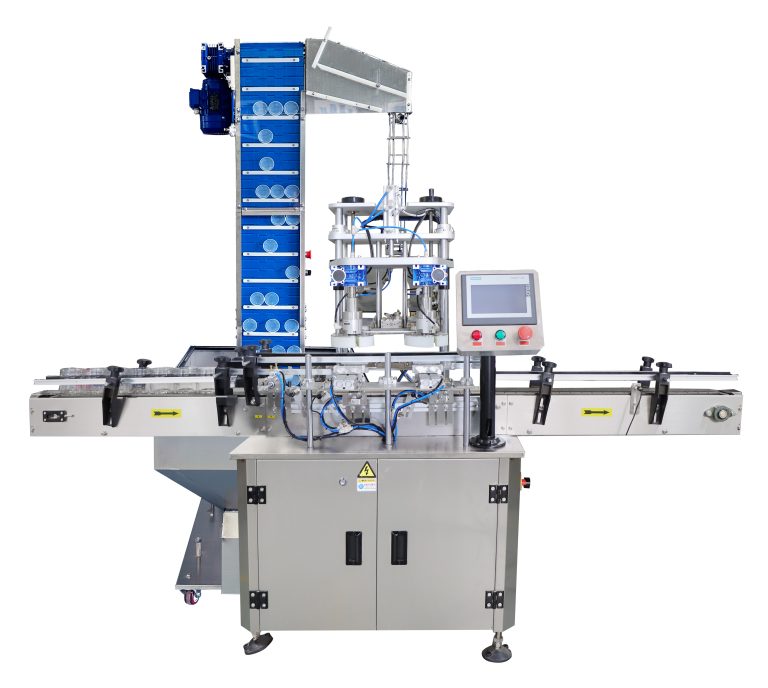

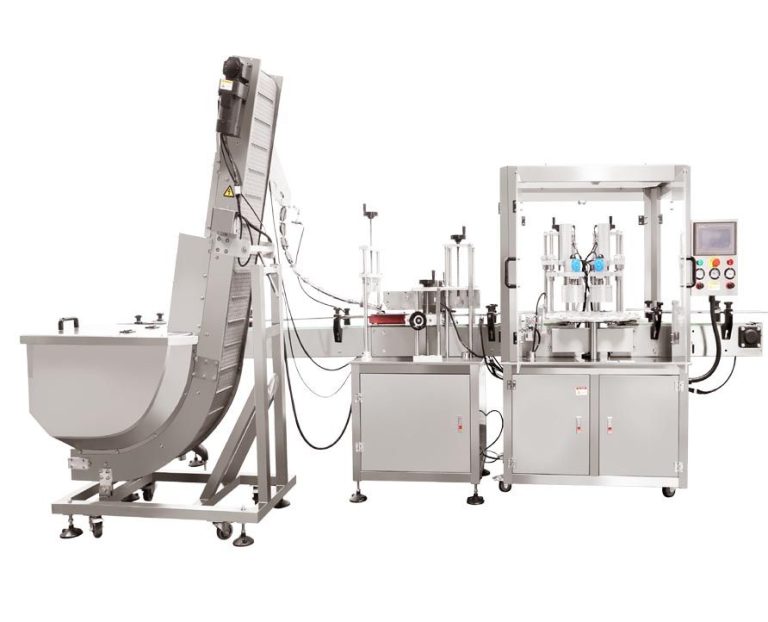

These machines are often designed with easy-to-load cap feeding systems, minimizing the time spent on preparing the caps for application.

Single-head servo capping machines can be seamlessly integrated into existing packaging lines. This smooth integration avoids disruptions and ensures a continuous flow of the packaging process, maximizing efficiency.

They are also equipped with intelligent sensors and control systems that can automatically detect and adjust for variations in container size or cap type. This eliminates the need for manual adjustments and keeps the capping process running smoothly without delays.

The reliability and low maintenance requirements of these machines mean less downtime for repairs or servicing, allowing for more consistent and efficient operation.

In conclusion, the combination of speed, precision, ease of use, integration capabilities, and reliability makes single-head servo capping machines a valuable asset in improving the efficiency of the packaging process.