Benefits of Using Tuna Can Sealing Machines

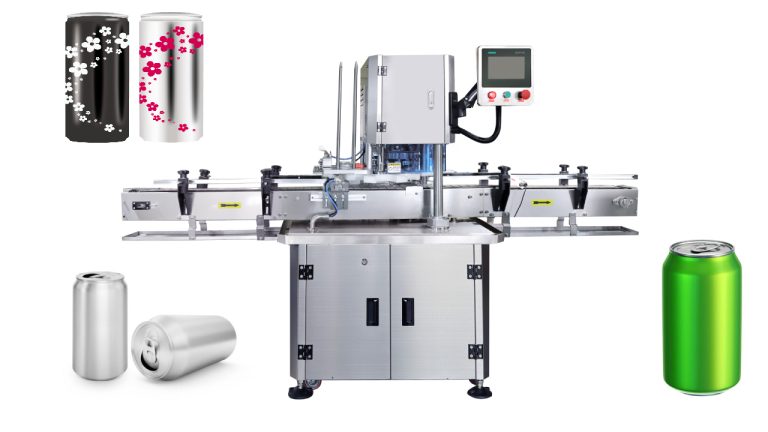

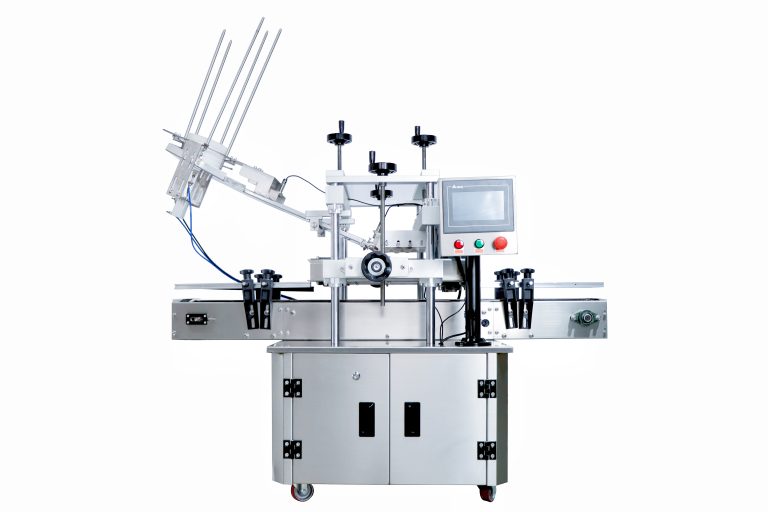

Tuna can sealing machines are an essential tool for any food processing facility that deals with canned tuna products. These machines offer a wide range of benefits that can help improve efficiency and productivity in the production process. In this article, we will explore some of the key advantages of using tuna can sealing machines and how they can help streamline operations.

One of the primary benefits of using tuna can sealing machines is the speed at which they can seal cans. These machines are designed to quickly and efficiently seal cans, allowing for a high volume of production in a short amount of time. This can help reduce bottlenecks in the production process and ensure that products are sealed and ready for distribution in a timely manner.

In addition to speed, tuna can sealing machines also offer a high level of accuracy and consistency in the sealing process. This helps to ensure that each can is properly sealed, reducing the risk of contamination or spoilage. By maintaining a consistent seal on each can, these machines can help improve the overall quality of the product and reduce the likelihood of product recalls due to faulty seals.

Another key benefit of using tuna can sealing machines is the reduction in labor costs. These machines are designed to automate the sealing process, eliminating the need for manual labor to seal cans. This can help reduce labor costs and free up employees to focus on other tasks within the production process. Additionally, the automation provided by these machines can help reduce the risk of human error in the sealing process, further improving the overall quality of the product.

Tuna can sealing machines are also designed to be easy to use and maintain. These machines are typically equipped with user-friendly interfaces that make them easy to operate, even for employees with minimal training. Additionally, many machines are designed to be easily cleaned and maintained, helping to ensure that they continue to operate at peak efficiency over time.

In addition to these benefits, tuna can sealing machines can also help improve overall safety in the production process. By automating the sealing process, these machines help reduce the risk of injuries that can occur when manually sealing cans. Additionally, the consistent and accurate sealing provided by these machines helps to reduce the risk of contamination or spoilage, ensuring that products are safe for consumption.

Overall, tuna can sealing machines offer a wide range of benefits that can help improve efficiency and productivity in the production process. From increased speed and accuracy to reduced labor costs and improved safety, these machines are an essential tool for any food processing facility that deals with canned tuna products. By investing in a high-quality tuna can sealing machine, businesses can streamline their operations and ensure that their products are sealed and ready for distribution in a timely and efficient manner.