Table of Contents

Benefits of Using an Automatic Can Seamer Machine

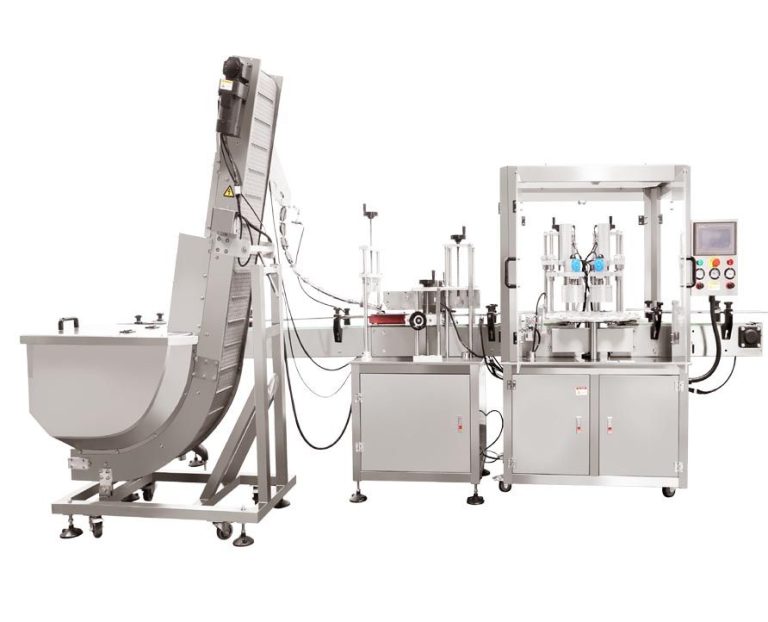

An automatic can seamer machine is a valuable piece of equipment for businesses in the food and beverage industry. This machine is designed to seal cans quickly and efficiently, saving time and labor costs. By automating the can sealing process, businesses can increase their production capacity and ensure a consistent seal on every can.

One of the key benefits of using an automatic can seamer machine is its speed. These machines are capable of sealing hundreds of cans per minute, far surpassing the output of manual sealing methods. This increased speed allows businesses to meet high demand and fulfill orders in a timely manner. Additionally, the consistent sealing provided by an automatic can seamer machine ensures that every can is properly sealed, reducing the risk of leaks or contamination.

Another benefit of using an automatic can seamer machine is its ease of use. These machines are designed to be user-friendly, with simple controls and settings that can be adjusted to accommodate different can sizes. This makes it easy for operators to set up the machine and start sealing cans quickly. Additionally, automatic can seamer machines are equipped with safety features to protect operators and prevent accidents.

In addition to speed and ease of use, automatic can seamer machines offer a high level of precision. These machines are designed to seal cans with a consistent and tight seal, ensuring that the contents remain fresh and protected from outside contaminants. This precision is essential for businesses that produce perishable goods or products that require a long shelf life.

Furthermore, automatic can seamer machines are highly efficient, reducing waste and increasing productivity. By automating the can sealing process, businesses can minimize the risk of human error and ensure that every can is sealed correctly. This efficiency not only saves time and labor costs but also reduces the likelihood of product spoilage due to improperly sealed cans.

Overall, the benefits of using an automatic can seamer machine are numerous. From increased speed and efficiency to precision and ease of use, these machines offer businesses a cost-effective solution for sealing cans. By investing in an automatic can seamer machine, businesses can streamline their production process, improve product quality, and ultimately increase their bottom line.

In conclusion, automatic can seamer machines are a valuable asset for businesses in the food and beverage industry. With their speed, precision, and efficiency, these machines offer a cost-effective solution for sealing cans and increasing production capacity. By investing in an automatic can seamer machine, businesses can improve their operations and ensure that every can is properly sealed and protected.

Step-by-Step Guide on Operating an Automatic Can Seamer Machine

Operating an automatic can seamer machine may seem like a daunting task at first, but with the right knowledge and guidance, it can be a straightforward process. In this step-by-step guide, we will walk you through the process of running an automatic can seamer machine efficiently and effectively.

First and foremost, it is essential to familiarize yourself with the machine and its components. Take the time to read the user manual thoroughly and understand how each part of the machine functions. This will help you operate the machine safely and prevent any potential accidents or damage.

Once you have a good understanding of the machine, the next step is to prepare the cans for sealing. Make sure the cans are clean and free of any debris or contaminants that could affect the sealing process. Additionally, ensure that the lids are properly aligned and ready to be sealed onto the cans.

Before starting the machine, it is crucial to adjust the settings according to the size of the cans and lids being used. This includes adjusting the seaming rollers, pressure settings, and speed of the machine to ensure a tight and secure seal. Take the time to make these adjustments carefully to avoid any issues during the sealing process.

Once the machine is set up and ready to go, it is time to start the can seaming process. Place the cans and lids onto the machine’s conveyor belt, making sure they are properly aligned and positioned for sealing. Press the start button to begin the sealing process, and monitor the machine closely to ensure everything is running smoothly.

As the cans move through the machine, pay attention to any potential issues such as misaligned lids or improper sealing. If you notice any problems, stop the machine immediately and make the necessary adjustments before continuing. It is essential to address any issues promptly to prevent any damage to the cans or the machine itself.

Once the sealing process is complete, carefully remove the sealed cans from the machine and inspect them for any defects or imperfections. Check the seals to ensure they are tight and secure, and make any necessary adjustments if needed. Properly sealed cans are essential to maintaining the quality and freshness of the products inside.

After the cans have been inspected and deemed satisfactory, it is important to clean and maintain the machine properly. Regular cleaning and maintenance will help prolong the life of the machine and ensure it continues to operate efficiently. Follow the manufacturer’s guidelines for cleaning and maintenance to keep the machine in optimal condition.

In conclusion, operating an automatic can seamer machine requires careful attention to detail and proper maintenance. By following this step-by-step guide, you can effectively run the machine and produce high-quality sealed cans for your products. Remember to familiarize yourself with the machine, prepare the cans properly, adjust the settings accordingly, monitor the sealing process, inspect the sealed cans, and maintain the machine regularly. With practice and diligence, you can master the art of operating an automatic can seamer machine and produce top-notch sealed cans every time.