Milk Powder Filling Process: A Comprehensive Guide

Milk powder is a popular dairy product that is used in a variety of food and beverage applications. From baking to cooking to making beverages, milk powder is a versatile ingredient that is in high demand. But have you ever wondered how milk powder is filled into containers? In this comprehensive guide, we will take a closer look at the milk powder filling process.

The milk powder filling process begins with the preparation of the milk powder itself. The milk powder is typically produced by evaporating milk to remove the moisture content, resulting in a dry powder that can be easily stored and transported. Once the milk powder is ready, it is then transferred to a filling machine.

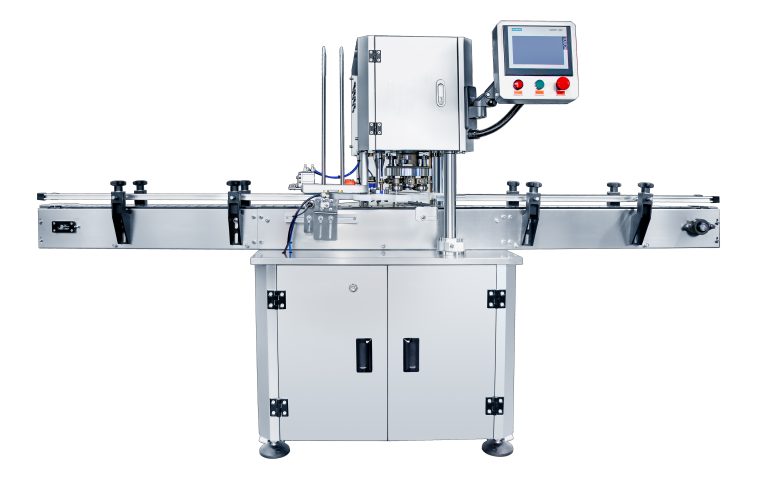

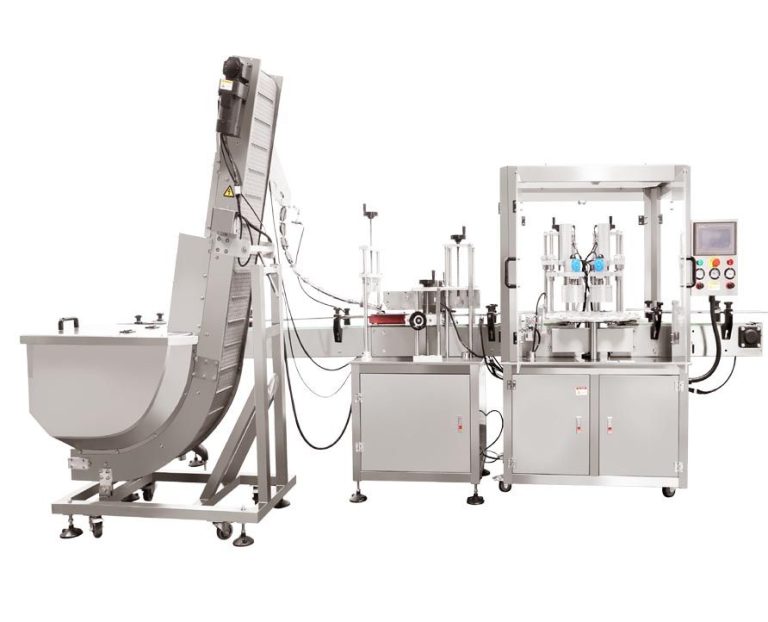

Filling machines are used to accurately fill containers with a specific amount of milk powder. These machines come in a variety of sizes and configurations, depending on the volume of milk powder that needs to be filled. The milk powder is fed into the filling machine, which then dispenses the powder into containers at a precise rate.

One of the key components of the milk powder filling process is the filling nozzle. The filling nozzle is responsible for dispensing the milk powder into containers with accuracy and precision. The size and shape of the filling nozzle can be adjusted to accommodate different container sizes and shapes, ensuring that the milk powder is filled evenly and consistently.

In addition to the filling nozzle, the filling machine also includes a conveyor system that moves containers through the filling process. The conveyor system ensures that containers are filled efficiently and without spillage. Once the containers are filled with milk powder, they are then sealed to prevent contamination and ensure product freshness.

The milk powder filling process is a highly automated and efficient process that can fill hundreds of containers per minute. This high-speed filling capability is essential for meeting the demands of the food and beverage industry, where large quantities of milk powder are required for production.

In addition to speed and accuracy, the milk powder filling process also prioritizes hygiene and cleanliness. The filling machine and all components that come into contact with the milk powder are made from food-grade materials that are easy to clean and sanitize. This ensures that the milk powder remains safe for consumption and free from contaminants.

Overall, the milk powder filling process is a complex and precise operation that requires specialized equipment and expertise. By understanding how milk powder is filled into containers, we can appreciate the level of technology and innovation that goes into producing this essential dairy product.

In conclusion, the milk powder filling process is a critical step in the production of milk powder. From the preparation of the milk powder to the filling machine to the sealing of containers, every aspect of the process is carefully controlled to ensure quality and consistency. Next time you enjoy a glass of milk or bake a batch of cookies, take a moment to appreciate the intricate process that goes into filling containers with milk powder.