Table of Contents

Benefits of Using Semi-Automatic Tape Sealing Machine for Rectangle Box

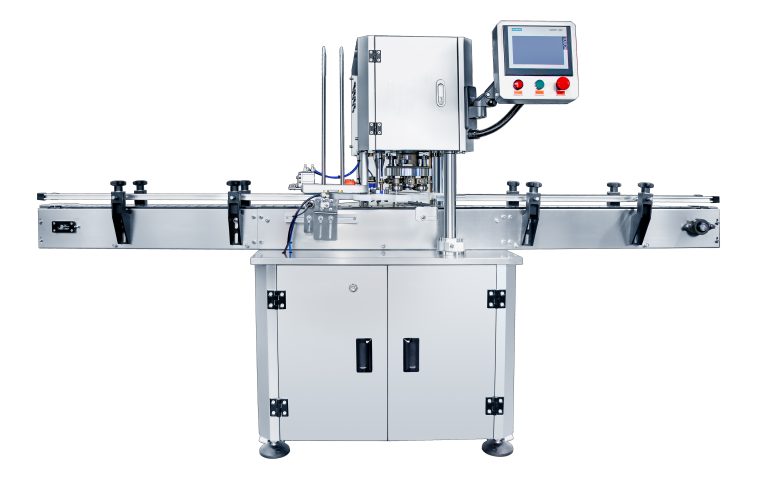

In the world of packaging and shipping, efficiency and accuracy are key factors in ensuring that products reach their destination safely and securely. One important tool that can help streamline the packaging process is the semi-automatic tape sealing machine for rectangle boxes. This machine offers a range of benefits that can make a significant difference in the packaging process for businesses of all sizes.

One of the primary benefits of using a semi-automatic tape sealing machine for rectangle boxes is the time-saving aspect. By automating the process of sealing boxes with tape, this machine can significantly reduce the amount of time it takes to prepare products for shipping. This can be especially beneficial for businesses that have a high volume of orders to fulfill on a daily basis. With a semi-automatic tape sealing machine, workers can seal boxes quickly and efficiently, allowing them to focus on other important tasks.

In addition to saving time, a semi-automatic tape sealing machine can also help improve the overall quality of packaging. By using a machine to seal boxes, businesses can ensure that each box is sealed securely and evenly, reducing the risk of damage during transit. This can help businesses maintain a positive reputation with customers by delivering products that are well-packaged and protected.

Another benefit of using a semi-automatic tape sealing machine for rectangle boxes is the cost-saving aspect. While there is an initial investment required to purchase the machine, the long-term savings can be significant. By reducing the amount of time and labor required to seal boxes, businesses can save money on labor costs and increase overall efficiency. Additionally, using a machine to seal boxes can help reduce the amount of tape used, further lowering packaging costs.

Furthermore, a semi-automatic tape sealing machine can also help improve workplace safety. Manual sealing of boxes with tape can be a repetitive and physically demanding task, which can lead to injuries such as repetitive strain injuries. By using a machine to seal boxes, businesses can reduce the risk of injuries to workers and create a safer work environment.

Overall, the benefits of using a semi-automatic tape sealing machine for rectangle boxes are clear. From saving time and improving packaging quality to reducing costs and enhancing workplace safety, this machine offers a range of advantages that can make a significant impact on businesses of all sizes. By investing in a semi-automatic tape sealing machine, businesses can streamline their packaging process and improve overall efficiency, ultimately leading to a more successful and profitable operation.

How to Choose the Right Semi-Automatic Tape Sealing Machine for Your Packaging Needs

When it comes to packaging products, efficiency and reliability are key factors to consider. One essential piece of equipment that can help streamline your packaging process is a semi-automatic tape sealing machine. These machines are designed to quickly and securely seal boxes with tape, saving you time and ensuring that your products are properly packaged for shipping or storage.

When choosing a semi-automatic tape sealing machine for rectangle boxes, there are several factors to consider. The first thing to think about is the size of the boxes you will be sealing. Make sure to choose a machine that can accommodate the dimensions of your boxes, as using a machine that is too small or too large can lead to inefficiencies and potential damage to your packaging.

Another important factor to consider is the type of tape that the machine is compatible with. Most semi-automatic tape sealing machines are designed to work with standard packaging tape, but some may be compatible with specialty tapes or reinforced tapes for added strength. Make sure to choose a machine that can handle the type of tape you will be using to ensure a secure seal on your boxes.

In addition to size and tape compatibility, it is also important to consider the speed and efficiency of the machine. Look for a machine that can seal boxes quickly and consistently, as this will help you increase productivity and meet your packaging deadlines. Some machines may also offer adjustable speed settings, allowing you to customize the sealing process to meet your specific needs.

Durability and reliability are also key factors to consider when choosing a semi-automatic tape sealing machine. Look for a machine that is made from high-quality materials and has a solid construction to ensure that it can withstand the rigors of daily use. Additionally, consider the reputation of the manufacturer and read reviews from other users to ensure that the machine is reliable and will perform consistently over time.

Finally, consider any additional features or accessories that may be beneficial for your packaging needs. Some semi-automatic tape sealing machines may offer features such as automatic tape dispensers, adjustable pressure settings, or safety features to protect operators during use. These additional features can help improve efficiency and safety in your packaging process.

In conclusion, choosing the right semi-automatic tape sealing machine for rectangle boxes is an important decision that can have a significant impact on your packaging process. Consider factors such as box size, tape compatibility, speed and efficiency, durability and reliability, and additional features when making your decision. By selecting a machine that meets your specific needs and requirements, you can streamline your packaging process and ensure that your products are securely sealed and ready for shipping or storage.

Maintenance Tips for Ensuring Longevity and Efficiency of Semi-Automatic Tape Sealing Machine

In the world of packaging and shipping, efficiency and reliability are key factors in ensuring that products reach their destination safely and securely. One essential piece of equipment that plays a crucial role in this process is the semi-automatic tape sealing machine for rectangle boxes. These machines are designed to streamline the packaging process by quickly and efficiently sealing boxes with tape, saving time and labor costs for businesses.

To ensure that your semi-automatic tape sealing machine continues to operate at peak performance, regular maintenance is essential. By following a few simple tips, you can help prolong the longevity and efficiency of your machine, ultimately saving time and money in the long run.

One of the most important maintenance tasks for a semi-automatic tape sealing machine is keeping it clean. Dust, dirt, and debris can build up over time and cause the machine to malfunction. Regularly cleaning the machine with a soft cloth and mild detergent can help prevent this buildup and keep the machine running smoothly.

In addition to keeping the machine clean, it is also important to regularly inspect and replace any worn or damaged parts. Over time, parts such as the tape dispenser, cutting blade, and rollers can become worn out and affect the machine’s performance. By inspecting these parts regularly and replacing them as needed, you can help ensure that your machine continues to operate efficiently.

Another important maintenance tip for a semi-automatic tape sealing machine is to regularly lubricate moving parts. Lubrication helps reduce friction and wear on the machine’s components, prolonging their lifespan and ensuring smooth operation. Be sure to use a lubricant that is recommended by the manufacturer and follow their guidelines for application.

In addition to regular cleaning, inspection, and lubrication, it is also important to calibrate the machine periodically. Calibration ensures that the machine is operating at the correct settings and can help prevent issues such as uneven tape application or sealing. Consult the manufacturer’s guidelines for calibration procedures and frequency to ensure that your machine is always operating at peak performance.

Finally, it is important to train your staff on proper machine operation and maintenance. By educating your employees on how to use the machine correctly and perform basic maintenance tasks, you can help prevent issues and prolong the lifespan of the machine. Encourage your staff to report any issues or concerns with the machine promptly so that they can be addressed before they escalate.

In conclusion, regular maintenance is essential for ensuring the longevity and efficiency of a semi-automatic tape sealing machine for rectangle boxes. By keeping the machine clean, inspecting and replacing worn parts, lubricating moving components, calibrating the machine, and training your staff on proper maintenance procedures, you can help prolong the lifespan of your machine and ensure that it continues to operate at peak performance. By following these simple tips, you can save time and money in the long run and keep your packaging process running smoothly.