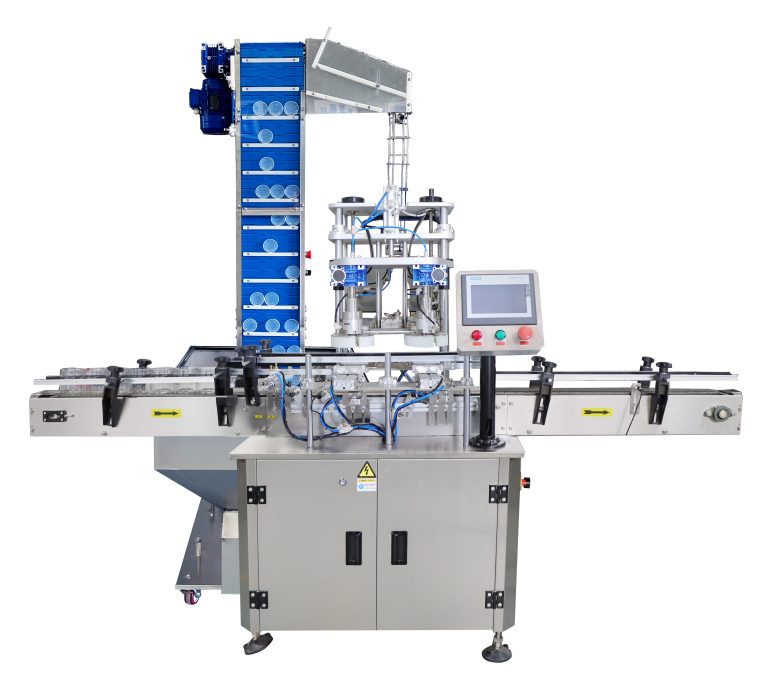

In the world of confectionery packaging, the automatic candy container taping around sealing machine is a remarkable innovation. This advanced piece of equipment is dedicated to ensuring the secure and attractive packaging of candies.

One of the key features of this machine is its speed and efficiency. It can seal a large number of candy containers in a short period, meeting the high production demands of the candy industry. This rapid sealing process helps manufacturers keep up with market demands and maintain a smooth supply chain.

The precision of the taping around sealing is impressive. It ensures a tight and uniform seal, protecting the candies from air, moisture, and other external factors that could affect their quality and freshness. The consistent sealing also gives the packaging a professional and appealing look, making the candies more attractive to consumers.

The automatic candy container taping around sealing machine is designed to handle various types and sizes of candy containers, offering flexibility to manufacturers. Whether it’s small individual packs or larger containers for bulk candies, this sealing machine can adapt and provide a perfect seal every time.

The automatic operation reduces the reliance on manual labor, minimizing the risk of human error and ensuring consistent quality across all sealed containers. This not only saves time but also improves the overall productivity and efficiency of the packaging process.

Maintenance of the automatic candy container taping around sealing machinee is relatively straightforward. Regular cleaning and inspection of key components, along with proper lubrication, can keep the machine running smoothly and extend its lifespan.

In summary, the automatic candy container taping around sealing machine is a vital tool for the confectionery industry. It combines speed, precision, and flexibility to provide secure and visually appealing packaging for candies, contributing to the success of candy brands in the marketplace.

Stay tuned for more insights and updates on the latest advancements in packaging machinery!