In the dynamic world of packaging, glass bottle vacuum capping machines are constantly evolving. These innovations are driven by the need for greater efficiency, enhanced product quality, and the ability to meet the diverse demands of various industries. Here are some of the latest advancements in this field.

Table of Contents

Advanced Vacuum Technology

Precision Vacuum Control

Modern glass bottle vacuum capping machines now feature highly precise vacuum control systems. These systems can accurately adjust the vacuum level inside the bottle according to the specific requirements of the product. For example, in the packaging of delicate beverages like champagne or fine wines, the machine can create a gentle vacuum to prevent excessive foaming or loss of carbonation. This precision is achieved through the use of advanced sensors and control algorithms that continuously monitor and adjust the vacuum pressure.

Faster Vacuum Generation

Newer machines are equipped with more powerful vacuum pumps that can generate the required vacuum in a much shorter time. This not only speeds up the capping process but also allows for higher production rates. For instance, in high – volume production lines for bottled sauces or condiments, the ability to quickly evacuate the air from the bottle and apply the cap is crucial for maintaining efficiency.

Intelligent Capping Mechanisms

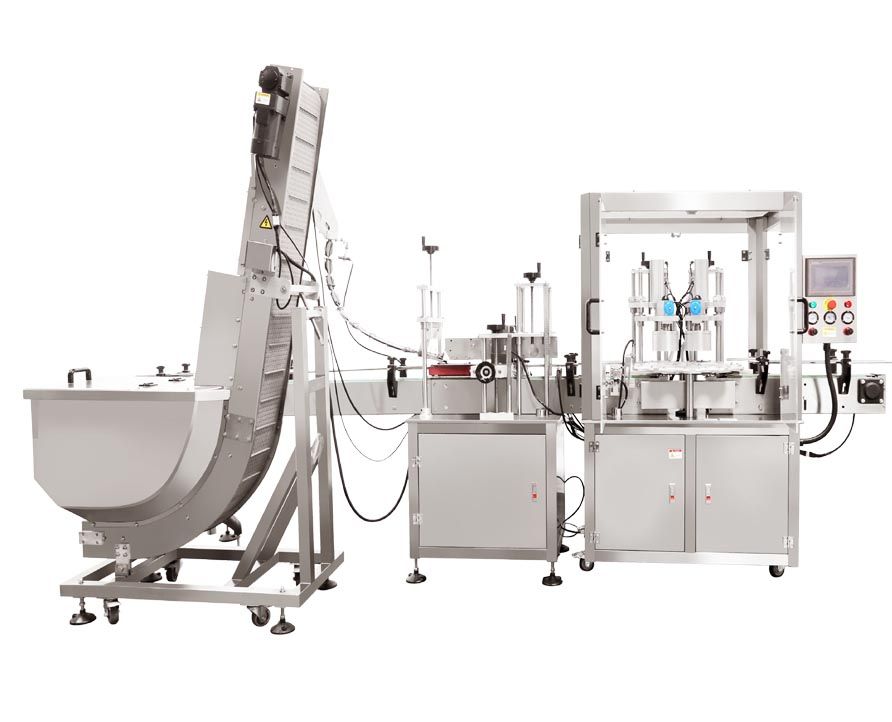

Adaptive Cap Placement

Innovative capping mechanisms can now adapt to different bottle and cap sizes and shapes. Using advanced vision systems and robotic arms, the machine can precisely position the cap on the bottle neck. This is particularly useful for companies that produce a wide range of products in various glass bottle formats. For example, a cosmetics manufacturer may use different – sized bottles for creams, lotions, and perfumes, and the capping machine can handle all of them with ease.

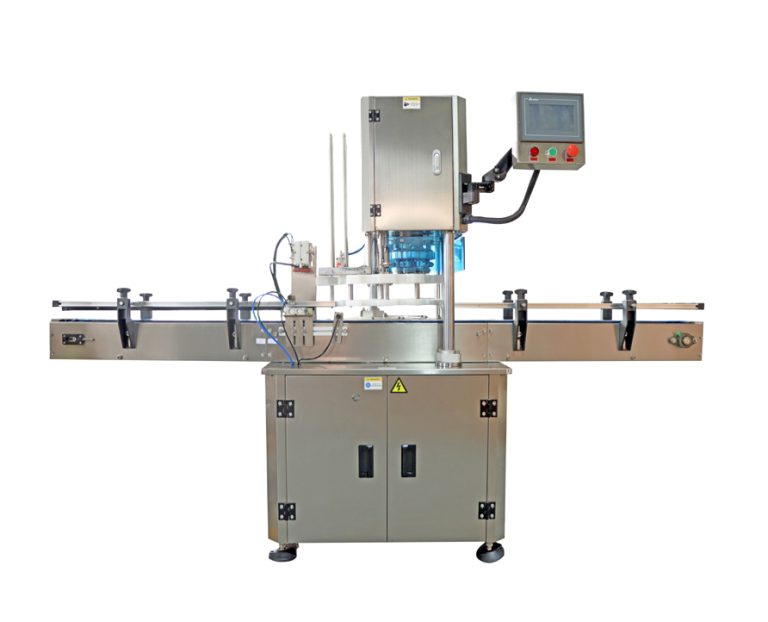

Self – Adjusting Torque

The torque applied during the capping process is critical for ensuring a tight and secure seal. The latest glass bottle vacuum capping machines are designed with self – adjusting torque systems. These systems can detect the type of cap and bottle material and automatically adjust the torque accordingly. This helps to prevent over – tightening, which could damage the bottle or cap, or under – tightening, which could lead to leaks.

Connectivity and Automation

IoT Integration

Many new glass bottle vacuum capping machines are being integrated with the Internet of Things (IoT). This allows the machine to communicate with other devices in the production line, as well as with central management systems. For example, the machine can send real – time data about its performance, such as the number of bottles capped, the vacuum levels achieved, and any error messages, to a cloud – based platform. This data can be accessed by managers and technicians from anywhere, enabling remote monitoring and control of the machine.

Automated Changeovers

To improve flexibility and reduce downtime, modern capping machines are equipped with automated changeover features. These features allow the machine to quickly switch between different bottle and cap sizes without the need for extensive manual adjustments. For example, a machine can be programmed to automatically adjust the height of the capping head, the position of the bottle holders, and the settings for the vacuum system when changing from a small – sized bottle to a large – sized one.

Hygiene and Sustainability

Easy – to – Clean Design

In industries such as food and pharmaceuticals, maintaining high levels of hygiene is essential. The latest glass bottle vacuum capping machines are designed with easy – to – clean surfaces and components. Smooth, rounded edges and removable parts make it easier to clean and sanitize the machine, reducing the risk of contamination.

Energy – Efficient Operation

With the growing focus on sustainability, manufacturers are developing capping machines that are more energy – efficient. These machines use advanced motors and control systems to reduce energy consumption during operation. For example, some machines can automatically adjust their power consumption based on the production volume, saving energy when the production rate is low.

In conclusion, the latest innovations in glass bottle vacuum capping machines are revolutionizing the packaging industry. These advancements are not only improving the efficiency and quality of the capping process but also addressing important issues such as connectivity, hygiene, and sustainability. As technology continues to develop, we can expect even more exciting innovations in the future.

-768x512.jpg)