It seems we can’t find what you’re looking for. Perhaps searching can help.

“The Ultimate Guide to Automatic Dual-Head Servo Can Seaming Machines”

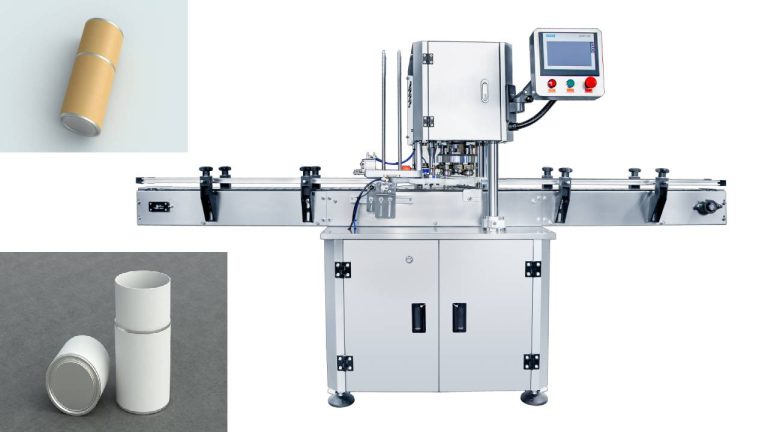

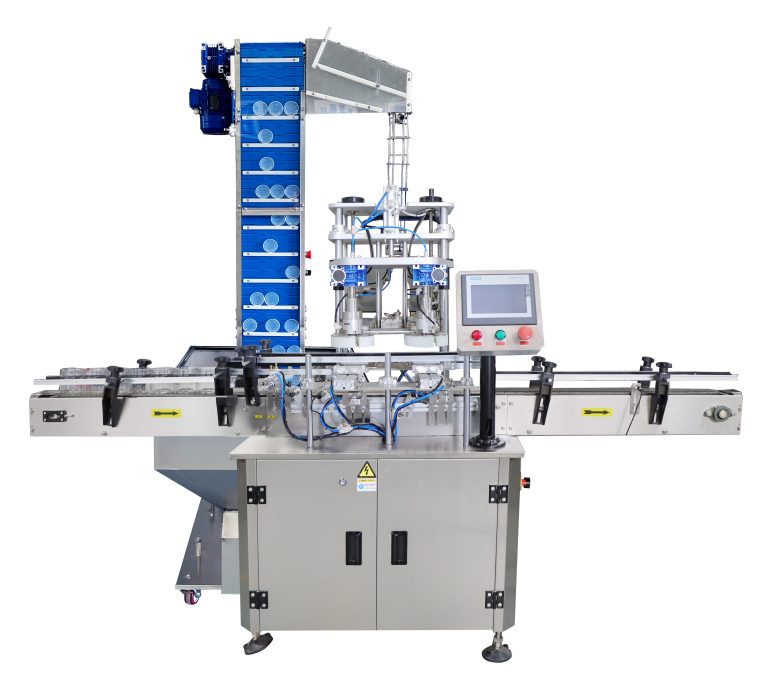

Automatic dual-head servo can seaming machines are essential in the packaging industry, offering efficient and high-quality can sealing. This ultimate guide will take you through everything you need to know about them. Let’s start with the basic structure and components. These machines typically consist of two seaming heads, a feeding…