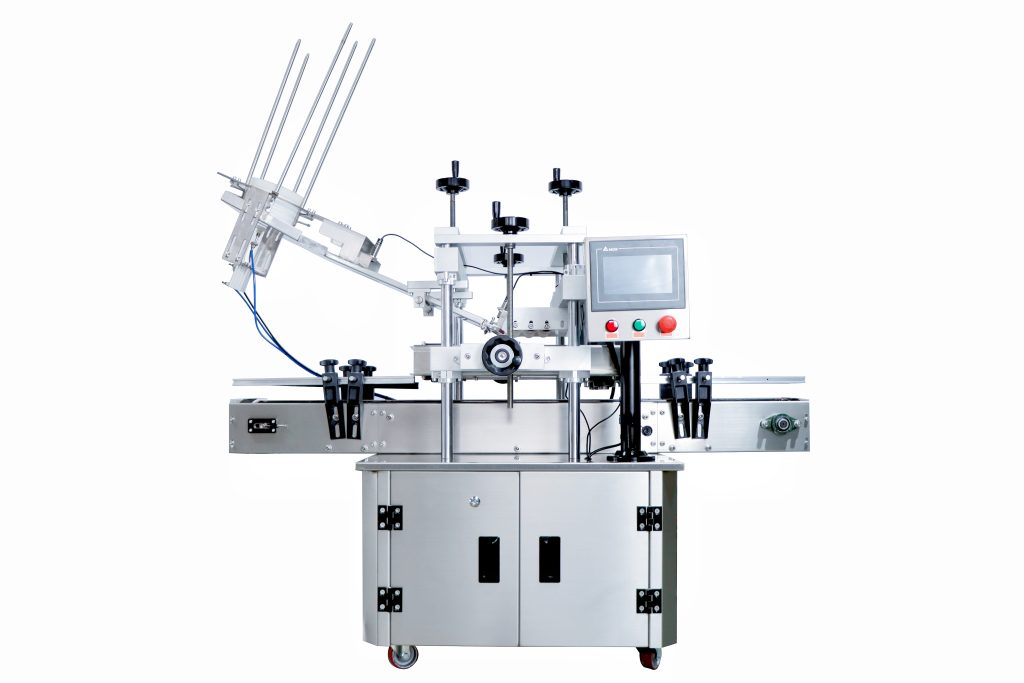

In the world of packaging, the automatic snap lid press capping machine is a remarkable piece of equipment that is transforming the way products are capped and sealed. This blog explores the features and benefits of this advanced machinery.

One of the standout features of the automatic snap lid press capping machine is its speed and efficiency. It can cap a large number of containers in a short period, significantly increasing production output. This is especially crucial in industries where high-volume packaging is the norm.

The precision with which it applies the snap lids is another key advantage. The machine ensures a tight and secure fit, minimizing the risk of leaks or loose lids. This not only protects the contents of the containers but also enhances the overall presentation of the packaged products.

The adaptability of the automatic snap lid press capping machine is impressive. It can handle various container shapes and sizes, as well as different types of snap lids. This flexibility allows manufacturers to switch between different products and packaging styles with ease.

The machine is often equipped with advanced control systems that enable operators to monitor and adjust settings for optimal performance. This ensures consistent capping quality and reduces the potential for errors.

Maintenance of the equipment is relatively straightforward. Regular inspections and servicing of key components can keep the machine running smoothly, minimizing downtime and maximizing its lifespan.

In conclusion, the automatic snap lid press capping machine is a game-changer in the packaging industry. Its ability to combine speed, precision, adaptability, and ease of maintenance makes it an indispensable tool for businesses looking to enhance their packaging processes and meet the demands of the market.

Stay tuned to our blogs for more detailed insights and updates on the latest advancements in packaging machinery!