Table of Contents

Benefits of Using an Automatic Table Salt Glass Bottle Linear Type Screw Capping Machine

In the food and beverage industry, packaging plays a crucial role in ensuring the quality and safety of products. One essential aspect of packaging is the sealing of containers, such as glass bottles, to prevent contamination and maintain product freshness. Manual capping can be time-consuming and prone to human error, which is why many companies are turning to automatic capping machines for efficiency and consistency.

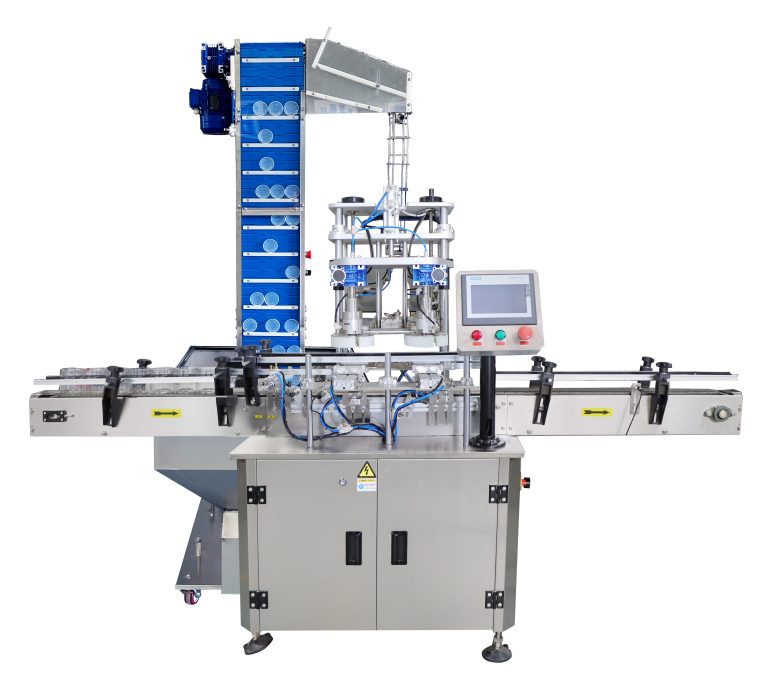

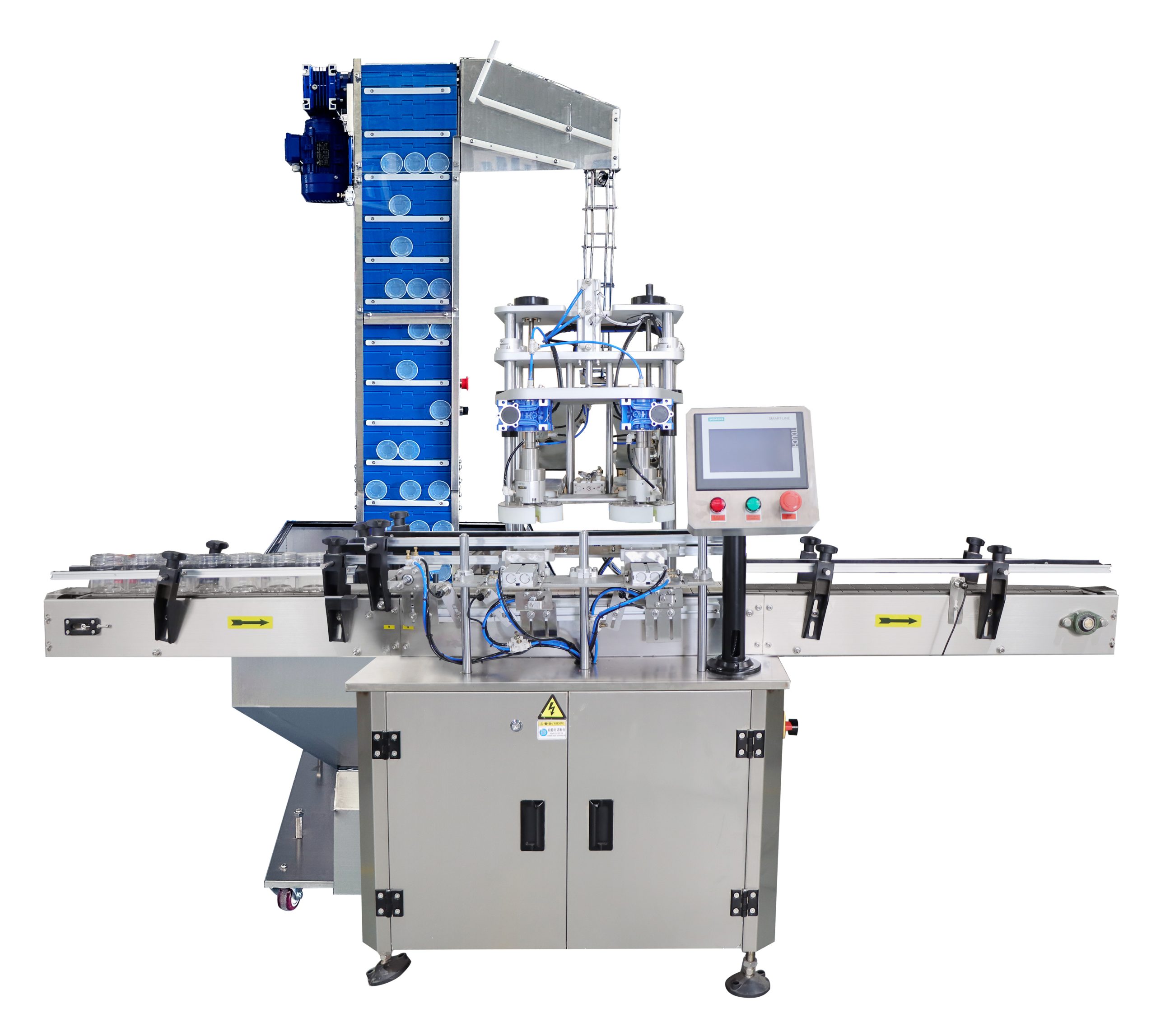

One popular type of automatic capping machine is the linear type screw capping machine, specifically designed for sealing glass bottles containing table salt. This machine offers numerous benefits that can greatly improve the packaging process and overall product quality.

One of the key advantages of using an automatic table salt glass bottle linear type screw capping machine is its speed and efficiency. These machines are capable of capping hundreds of bottles per minute, significantly increasing production output compared to manual capping. This high-speed operation allows companies to meet customer demands and deadlines more effectively, ultimately improving overall productivity.

In addition to speed, automatic capping machines also offer a high level of precision and consistency. The linear type screw capping machine is designed to apply the correct amount of torque to each bottle cap, ensuring a secure seal without over-tightening or damaging the cap. This level of precision helps to maintain product quality and integrity, reducing the risk of leaks or contamination during storage and transportation.

Furthermore, automatic capping machines are easy to operate and require minimal training for staff. Once the machine is set up and calibrated for a specific bottle size and cap type, it can run continuously with minimal supervision. This not only saves time and labor costs but also reduces the likelihood of human error, resulting in more consistent and reliable capping results.

Another benefit of using an automatic table salt glass bottle linear type screw capping machine is its versatility. These machines can be easily adjusted to accommodate different bottle sizes and cap types, making them suitable for a variety of packaging needs. Whether you are capping small or large bottles, or using different types of caps such as screw caps or snap caps, an automatic capping machine can handle the job efficiently and effectively.

Additionally, automatic capping machines are designed to be durable and long-lasting, requiring minimal maintenance and upkeep. This reliability ensures consistent performance over time, reducing downtime and production interruptions. With proper care and maintenance, an automatic capping machine can provide years of reliable service, making it a cost-effective investment for any packaging operation.

In conclusion, the benefits of using an automatic table salt glass bottle linear type screw capping machine are clear. From increased speed and efficiency to precision and consistency, these machines offer numerous advantages that can greatly improve the packaging process and product quality. With their versatility and durability, automatic capping machines are a valuable asset for any food and beverage company looking to streamline their packaging operations and enhance overall efficiency.

How to Choose the Right Automatic Table Salt Glass Bottle Linear Type Screw Capping Machine for Your Business

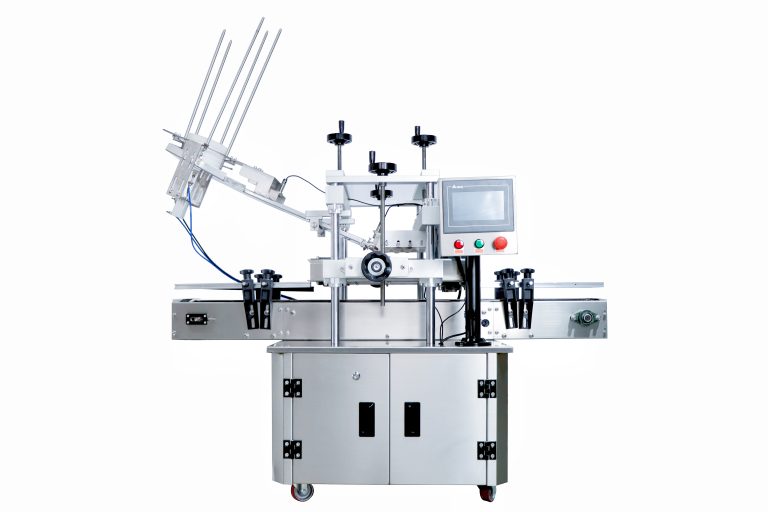

When it comes to packaging products like table salt in glass bottles, having the right capping machine is essential for ensuring efficiency and consistency in the production process. One popular option for this task is the automatic table salt glass bottle linear type screw capping machine. This machine is designed to automatically cap glass bottles with screw caps in a linear fashion, making it ideal for high-volume production lines. If you are considering investing in one of these machines for your business, there are several factors to consider to ensure you choose the right one for your specific needs.

One of the first things to consider when choosing an automatic table salt glass bottle linear type screw capping machine is the speed and capacity of the machine. Different machines have different capacities and speeds, so it is important to choose one that can keep up with the demands of your production line. Consider factors such as the size of your production runs and the speed at which you need to cap bottles to determine the right capacity and speed for your business.

Another important factor to consider is the size and shape of the bottles you will be capping. Automatic table salt glass bottle linear type screw capping machines come in a variety of sizes and configurations to accommodate different bottle sizes and shapes. Make sure to choose a machine that is compatible with the bottles you will be using to ensure a proper fit and consistent capping results.

In addition to size and capacity, it is also important to consider the level of automation and customization options available with the machine. Some machines offer more advanced automation features, such as automatic cap feeding and bottle positioning, which can help streamline the production process and improve efficiency. Additionally, some machines offer customization options for adjusting capping pressure and torque to ensure a secure and consistent seal on each bottle.

When choosing an automatic table salt glass bottle linear type screw capping machine, it is also important to consider the overall build quality and reliability of the machine. Look for machines that are made from durable materials and have a reputation for reliability and longevity. Investing in a high-quality machine may require a larger upfront investment, but it can save you money in the long run by reducing downtime and maintenance costs.

Finally, consider the level of support and service offered by the manufacturer of the capping machine. Look for a company that offers comprehensive training and support services to help you get the most out of your investment. Additionally, consider factors such as warranty coverage and availability of replacement parts to ensure that you can keep your machine running smoothly for years to come.

In conclusion, choosing the right automatic table salt glass bottle linear type screw capping machine for your business requires careful consideration of factors such as speed, capacity, bottle compatibility, automation features, build quality, and support services. By taking the time to research and evaluate your options, you can find a machine that meets your specific needs and helps you streamline your production process for maximum efficiency and consistency.