Table of Contents

Benefits of Using a Fully Automatic Pineapple Juice Tin Can Sealing Machine

In the food and beverage industry, efficiency and consistency are key factors in ensuring the quality of products. One important aspect of this process is the sealing of tin cans, which helps to preserve the freshness and flavor of the contents inside. Fully automatic pineapple juice tin can sealing machines are a valuable tool in this process, offering a range of benefits that can help businesses streamline their operations and improve the overall quality of their products.

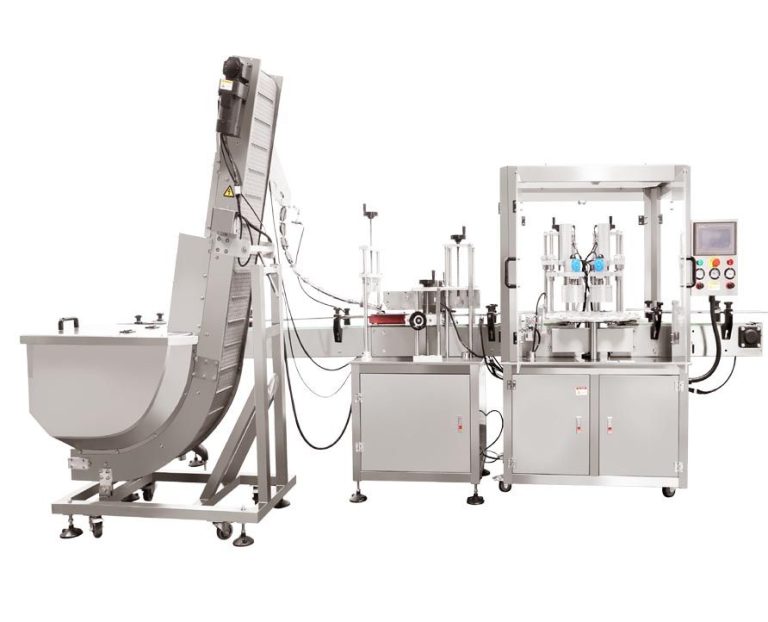

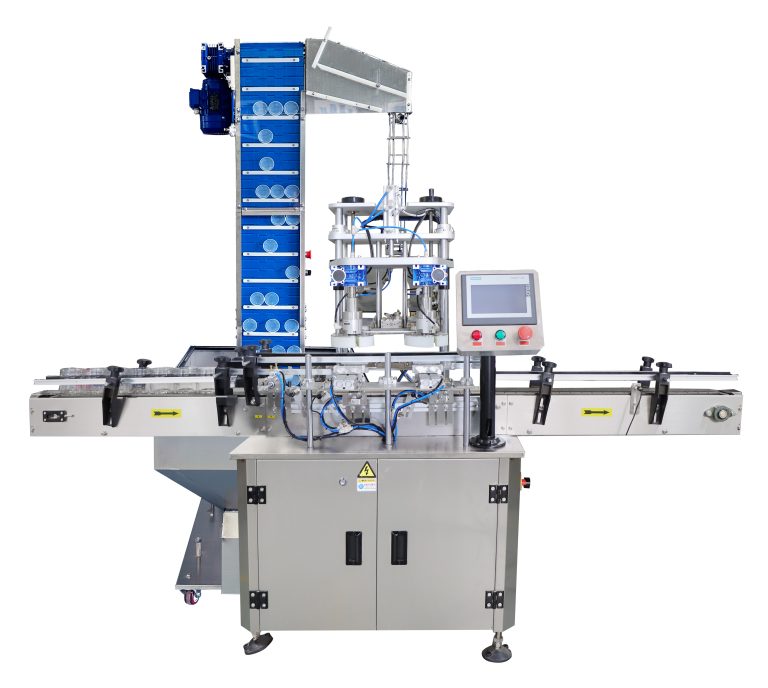

One of the primary benefits of using a fully automatic pineapple juice tin can sealing machine is the speed and efficiency it offers. These machines are designed to seal cans quickly and accurately, reducing the time and labor required for this task. This can help businesses increase their production output and meet the demands of a fast-paced market.

In addition to speed, fully automatic pineapple juice tin can sealing machines also offer a high level of consistency and precision. These machines are programmed to seal cans with a tight and secure seal every time, ensuring that the contents are properly preserved and protected from contamination. This level of consistency is essential for maintaining the quality and integrity of the product, which can help businesses build a strong reputation for reliability and excellence.

Another benefit of using a fully automatic pineapple juice tin can sealing machine is the reduction of human error. Manual sealing processes can be prone to mistakes, such as improper sealing or contamination of the contents. By automating this process, businesses can minimize the risk of errors and ensure that each can is sealed correctly every time. This can help to improve the overall quality of the product and reduce the likelihood of costly recalls or customer complaints.

Fully automatic pineapple juice tin can sealing machines are also designed to be easy to operate and maintain. These machines are equipped with user-friendly interfaces and controls, making them accessible to operators of all skill levels. Additionally, many models are equipped with self-cleaning and maintenance features, reducing the time and effort required to keep the machine running smoothly. This can help businesses save time and resources, allowing them to focus on other aspects of their operations.

In conclusion, fully automatic pineapple juice tin can sealing machines offer a range of benefits that can help businesses improve their efficiency, consistency, and overall product quality. By investing in one of these machines, businesses can streamline their operations, reduce the risk of errors, and build a strong reputation for reliability and excellence. With their speed, precision, and ease of use, fully automatic pineapple juice tin can sealing machines are a valuable asset for any food and beverage business looking to enhance their production processes.

How to Choose the Right Fully Automatic Pineapple Juice Tin Can Sealing Machine for Your Business

In the food and beverage industry, efficiency and quality are key factors in ensuring the success of a business. When it comes to packaging products such as pineapple juice, having the right equipment can make a significant difference in the overall production process. One essential piece of equipment for packaging pineapple juice is a fully automatic tin can sealing machine. These machines are designed to seal tin cans quickly and efficiently, ensuring that the product is properly sealed and preserved for consumption.

When choosing a fully automatic pineapple juice tin can sealing machine for your business, there are several factors to consider. The first factor to consider is the size and capacity of the machine. Depending on the volume of pineapple juice that your business produces, you will need to choose a machine that can handle the required capacity. It is important to select a machine that can keep up with the demand of your production line to avoid any bottlenecks in the packaging process.

Another important factor to consider when choosing a fully automatic tin can sealing machine is the sealing mechanism. There are different types of sealing mechanisms available, including vacuum sealing, hot sealing, and cold sealing. Each type of sealing mechanism has its own advantages and disadvantages, so it is important to choose a machine that is best suited for the specific requirements of packaging pineapple juice. Vacuum sealing, for example, is ideal for preserving the freshness and flavor of the juice, while hot sealing is more suitable for sealing cans quickly and efficiently.

In addition to the size, capacity, and sealing mechanism, it is also important to consider the overall quality and durability of the machine. A fully automatic pineapple juice tin can sealing machine is a significant investment for any business, so it is important to choose a machine that is built to last and can withstand the rigors of daily use. Look for machines that are made from high-quality materials and have a reputation for reliability and longevity.

When researching different models of fully automatic tin can sealing machines, it is also important to consider the ease of maintenance and operation. Look for machines that are easy to clean and maintain, as this will help to prolong the life of the machine and ensure that it continues to operate efficiently. Additionally, choose a machine that is user-friendly and easy to operate, as this will help to streamline the packaging process and reduce the risk of errors or downtime.

In conclusion, choosing the right fully automatic pineapple juice tin can sealing machine for your business is a crucial decision that can have a significant impact on the efficiency and quality of your production process. Consider factors such as size, capacity, sealing mechanism, quality, durability, maintenance, and operation when selecting a machine that is best suited for packaging pineapple juice. By investing in a high-quality and reliable machine, you can ensure that your pineapple juice is properly sealed and preserved, helping to maintain the freshness and flavor of the product for your customers.

Maintenance Tips for Ensuring the Longevity of Your Fully Automatic Pineapple Juice Tin Can Sealing Machine

Maintaining a fully automatic pineapple juice tin can sealing machine is essential to ensure its longevity and optimal performance. Regular maintenance not only extends the lifespan of the machine but also helps prevent breakdowns and costly repairs. In this article, we will discuss some maintenance tips to help you keep your fully automatic pineapple juice tin can sealing machine in top condition.

One of the most important maintenance tasks for your sealing machine is regular cleaning. Over time, residue from pineapple juice and other liquids can build up on the machine’s components, leading to decreased efficiency and potential malfunctions. To prevent this, it is recommended to clean the machine thoroughly after each use. Use a mild detergent and warm water to clean the surfaces and components of the machine, paying special attention to areas where residue tends to accumulate.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear and tear. Check the seals, gaskets, and other components for any damage or deterioration. Replace any worn-out parts immediately to prevent leaks and ensure a tight seal on the cans. Regular inspections can help you catch potential issues early on and prevent more serious problems down the line.

Another important maintenance tip is to lubricate the moving parts of the machine regularly. Proper lubrication helps reduce friction and wear on the components, ensuring smooth operation and extending the lifespan of the machine. Use a food-grade lubricant recommended by the manufacturer to lubricate the moving parts, such as the conveyor belts, rollers, and gears. Be sure to follow the manufacturer’s guidelines for lubrication frequency and amount to avoid over-lubrication.

In addition to cleaning, inspecting, and lubricating the machine, it is also important to calibrate the machine regularly. Calibration ensures that the machine is operating at the correct settings and producing consistent results. Follow the manufacturer’s instructions for calibration and make any necessary adjustments to ensure the machine is sealing cans properly. Regular calibration can help maintain the quality of your pineapple juice products and prevent issues with sealing.

Lastly, it is important to train your staff on proper machine operation and maintenance procedures. Ensure that your employees are familiar with the machine’s functions, safety protocols, and maintenance requirements. Provide training on how to clean, inspect, lubricate, and calibrate the machine to ensure it is being properly maintained. Regular training can help prevent operator errors and ensure the longevity of your fully automatic pineapple juice tin can sealing machine.

In conclusion, regular maintenance is key to ensuring the longevity and optimal performance of your fully automatic pineapple juice tin can sealing machine. By following these maintenance tips, you can keep your machine in top condition and prevent costly repairs. Remember to clean the machine regularly, inspect for wear and tear, lubricate moving parts, calibrate the machine, and train your staff on proper maintenance procedures. With proper care and maintenance, your sealing machine will continue to seal cans efficiently and produce high-quality pineapple juice products for years to come.